インダクトサーモ炉は、金属を非常に高い温度まで加熱し、完全に溶かすことができる特殊な機械の一種です。これらは自動車や航空業界など、さまざまな産業で使用され、金属製品を作り出しています。このクールな装置について、その仕組みや、なぜ現代の金属鋳造にインダクトサーモ炉が最適なのかをさらに学んでください。

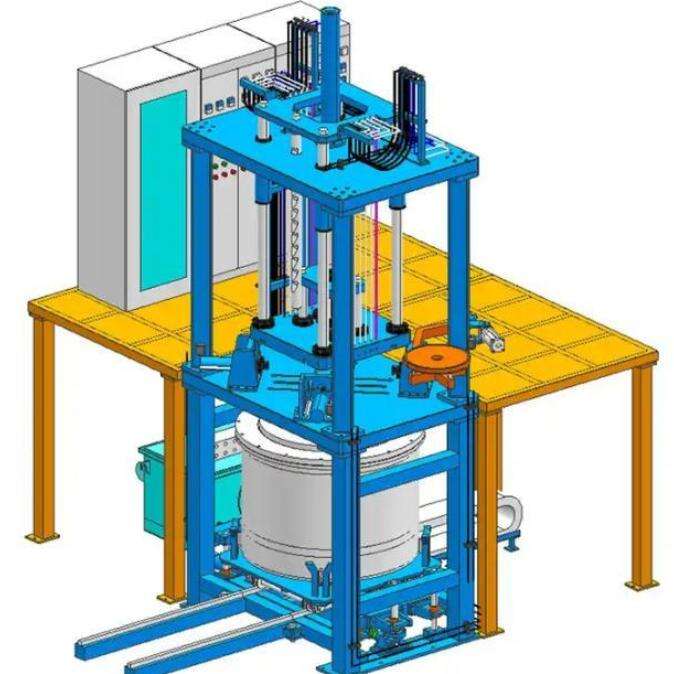

このボキアオ 重力ダイカスト機 は世界クラスのインダクトサーモ炉で、電磁波を使って金属を加熱します。これを誘導加熱と呼びます。炉の中には銅線コイルがあり、これが加熱プロセスにおいて重要な電場を生成します。これらの電磁波は、金属を炉に入れると、金属内の小さな粒子である分子を非常に高速に動かし、金属を加熱します。手を素早くこすると暖かくなるのと同じ原理ですが、これは大規模でさらに高温になります!

インダクトサーモ炉で発生する熱は高出力であり、金属を急速に融解温度に達させます。したがって、これは他の従来のプロセスと比較して、金属を迅速にさまざまな形状に成形することができます。このボキョウ 低圧ダイカスト機 この能力こそが、インダクトサーモ炉を他の多くの種類の炉から区別するものであり、いかなる金属もこのような高い効率で加熱するという並外れた能力を持っています

インダクトサーモ炉は、さまざまな産業の要件に対応するために、多くの形状やサイズで製造されています。他のものは小さく、鋳造所と呼ばれる工場で金属のかけらを溶かします。これらの小型炉は、小型金属製品の生産に理想的です。それとは対照的に、一度に100トンの金属を加熱できる大型のインダクトサーモ炉もあります。これまでに稼働した最大のインダクトサーモ炉は、驚異的な600トンの容量を持っています!そのため、大量の金属を一度に溶かす必要がある大規模プロジェクトには、これが最適な金属溶解機です。

これらの炉はさまざまなサイズがあり、異なる用途に使用できます。小さな作業場にも見られますが、工業プラントでも使用されます。大規模な例として、ボチャオがあります。 BQ溶融炉 それぞれの炉は、金属生産の異なるプロセスで役立ちます。

その装置を使用して材料を処理することで、すべての金属製品を作る未来は確実に明るくなってきています。金属をさまざまな形状に成型するプロセスは「金属鋳造」と呼ばれ、自動車(車)、航空宇宙(飛行機)、医療機器などの様々な産業に影響を与えています。溶解に関しては、Inductotherm炉が他のいかなるシステムよりも下流の競合手法よりもはるかに効率的な金属精錬を行います。この BQ淬火炉 速度と効率こそが、これらの分野における企業にとって大きな資産となる理由です。

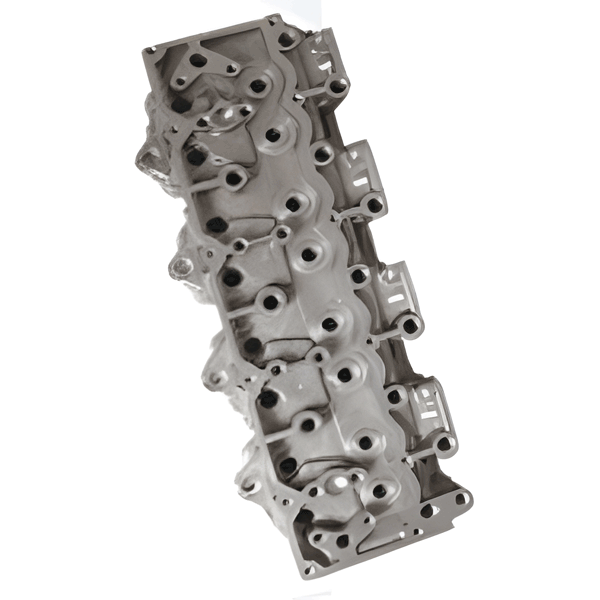

将来において、Inductotherm炉のさらに素晴らしい応用例が見られるかもしれません。例えば、再生可能エネルギーからエネルギーを生成する新しいタイプのデバイスを作成するために役立つ可能性があります。宇宙探査もまた、 アルミニウム鋳造部品 上述のすべての分野と同様に、大気圏外でのミッション中に必要に応じて補充部品や救命用の部品・道具を作り出すために、この技術が有用であることが期待されます。

南京博橋機械有限公司(Nanjing BoQiao Machinery Co., Ltd)は、各種鋳造機械、インダクソサーミック炉(Inductotherm furnace)および産業用炉の設計・製造・販売を専門とするメーカーです。現在、重力鋳造機、低圧鋳造機、溶解炉、焼鈍炉、焼入れ炉、時効処理炉、横磁界炉など、計18種類・約100種類の仕様を持つ製品ラインナップを展開しています。当社では、技術支援、設備選定および製造工程の検討、設計、教育訓練、操業支援を含むトータルソリューションを提供しています。当社製品は、お客様に価値を創出します。当社製品は、電力金具、オートバイ部品、自動車部品、新エネルギー、電子・電気機器、高圧スイッチ、建設機械、航空宇宙用鋳物、ファン、家庭用電化製品など、多様な専門鋳造生産企業で広く採用されています。

当社のインダクソサーミック炉は、1999年以降、累計2,000台以上を販売・製造してきました。信頼性の高い品質と優れたサービスにより、当社は顧客の間で非常に高い評価を獲得しています。国内では、すべての都市および省をカバーする販売網を有しており、さらに東南アジア、アフリカ、南アメリカ、中東など世界各地にも製品を輸出しており、いずれの地域でも顧客から大変好評をいただいております。相互に利益を得る「ウィンウィン」の協力関係、誠実さと正直さを基本理念として、ボーチャオ(BoQiao)は今後も専門性を高める道を一貫して歩み続け、製品およびサービスの継続的な向上を通じて、お客様のニーズにより的確にお応えしてまいります。そして、お客様がより多くの価値を創出できるよう、全力で支援してまいります。

ボーチャオ・インダクソサーミック炉は、コンパクトな構造で設計されており、さまざまな製造環境に最適な選択肢となります。最高品質の性能により、効率的かつ高精度な鋳造が保証され、使いやすいインターフェースによって生産プロセスが簡素化され、ユーザーは最小限の訓練で最良の結果を得ることができます。この多機能マシンは、オートバイ部品、自動車部品、電力設備用金具、および建設機械など、複数の業界で広く利用されています。低コストでありながら長寿命であるという特長から、堅牢な鋳造ソリューションを求める企業にとって優れた選択肢です。顧客は、この機械の安定した品質と、操作・保守の容易さを高く評価しており、これによりダウンタイムが削減され、生産性が向上します。

インダクソサーミ炉社の炉において、当社は鋳鉄分野への参入を、鋳造部品の販売から始めました。これが当社の市場における知識と存在感の出発点でした。長年にわたり、高品質な製品と優れたサービスを提供することで、顧客との長期にわたる信頼関係を築いてまいりました。1997年には、産業用電気炉の製造事業へと事業領域を拡大しました。この戦略的展開により、顧客に対してより包括的なソリューションを提供し、信頼性・効率性の高い加熱設備に対するニーズの高まりにも応えることが可能となりました。この時期における当社の革新への取り組みおよび最高水準の品質へのこだわりは、競合他社とは一線を画す明確な特徴でした。2002年にはさらに事業を拡大し、鋳造設備の製造分野へ参入しました。これにより、機械から材料に至るまで多様な鋳造ソリューションを包括的に提供できる体制が整い、顧客が鋳造に関するあらゆる要件を当社に一括してお任せいただけるようになりました。当社が蓄積してきた豊富な経験と業界に対する包括的な理解は、高品質な鋳造設備およびサービスを求める企業にとって信頼される企業であるという地位を確立しています。長い歴史を通じて、当社は継続的な改善と顧客満足への献身を貫き、変化する市場環境に柔軟に対応し、成長を続けています。