×

×

An interesting new innovation in casting is what they are doing with computers to create 3D models. Then they can use computer programs to make a digital drawing with hidden lines of the object that will be made. They simply take the digital model and use casting tools to cast a physical replica of the object. This Gravity die casting machines is a major boon for hospitals and other health care facilities. Medics could employ 3D printed models for fabricate unique parts such as prosthetics servicing people requiring them. That Boqiao gives every object the ability to be personalized, which is extremely important aspect for health and well being. Background Effect in Casting Technology Another amazing progress came when various sorts of metals have been blended inside the semi-solidified state, which we name metal compounds. This is used in the titanium aluminide to create materials significantly stronger than standard metals by alloying other elements. It is very useful in constructions, as buildings and other construction-related things require solid materials that will last long periods of time (to be sturdy against different climates). It contributes to the smoother functioning of industries where these heavy materials are used and guarantees that those structures remain intact which is how it keeps all inhabitants out there safe.

It is also useful to know that different materials require somewhat differently casting. One of the Boqiao most popular motivations for investing in aluminium casting is that metals are ostensibly easier to looks after than plastics when it comes time to maintenance or cleaning. Therefore, it Low Pressure die cast machines is necessary to be prepared on how the material you are using will behave best cast. I recommend that you do a little reading to learn which methods are most effective with each different material yourself.

Finally, you will need to opt for quality when it comes to buying assembling tools. Cheap tools might seem a significant cost saving, however good-quality tools will last longer and perform much better. Various equipment costs a considerable amount of money, so for it to stop working in such less time calls for us to shell out more cash on its replacement.

There Boqiao are several jobs in a number of industries where casting tools play a vital role. In the BQ melting furnace automotive industry, casting is heavily utilized in manufacturing automobile parts such as engine blocks and other essential car components. It would be impossible to manufacture most of these components accurately and without the use of casting.

Casting is a process used in the jewelry making industry to fashion detail and quality designs that otherwise would not be possible when using conventional techniques. The casting gives a route to create many beautiful pieces of jewelry that we can see today. This BQ quenching furnace means it helps to take your creative visions from concept stages to reality in a way that other approaches just cannot.

Casting is also employed in the medical industry to build special contraptions for patients. And these medical devices need to be customized to the requirements of every individual. This Aluminum casting parts ability to customize all of these features relates back to casting and the higher-quality care that patients get. Casting for example can be used to cast a perfect fitting and still largely seamless prosthetic limb for the wearer.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Casting apparatus customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

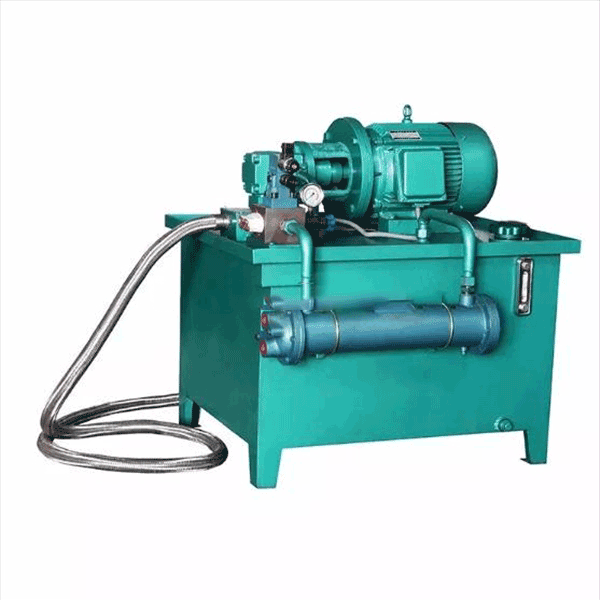

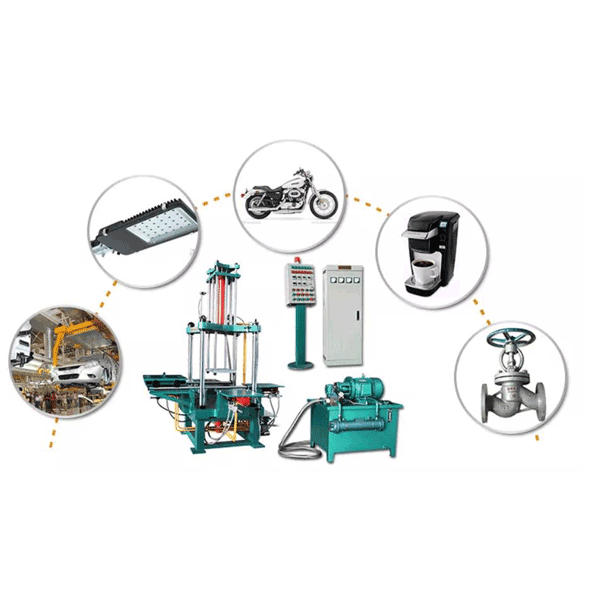

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various Casting apparatus, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer customers all kinds of overall solutions and turnkey project services, such as technical consultation, equipment selection, mold manufacturing design, process development as well as operation training and much more. We are confident that our products will create value to our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

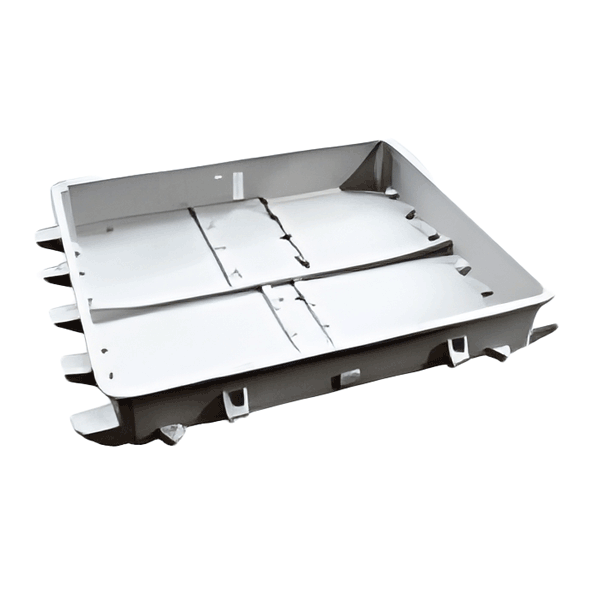

BoQiao's gravity cast machine is a compact design, which makes it a good choice for a range of manufacturing settings. The Casting apparatus of the machine ensures accurate and efficient casting while its user-friendly system simplifies the production process, which allows users to get the best outcomes with only minimal training. This multi-purpose machine is used in a variety of industries, such as motorcycle parts automobile parts and electric power fittings as well as engineering equipment. The durability and affordability are a great investment for businesses seeking solid casting solutions. The machine is highly regarded by customers for its consistent high-quality, simple operating and maintenance, and the increased production.

Our journey into the casting industry started in 1979 with sales of casting materials creating a Casting apparatus for our experience and market presence We have built lasting relations with our clients throughout time by providing high-end products as well as providing outstanding customer service In 1997 we began to include the manufacturing of industrial electric heaters This was a smart move that enabled us to offer a wider range of solutions to our clients addressing their growing demands for efficient and reliable heating equipment Our commitment to innovation and the highest quality in this period stood us out in the competitive landscape By 2002 we further broadened our offerings of products by joining the casting equipment manufacturing sector We could offer an array of options to casting encompassing materials and machines This enabled us to be a one-stop store for our customers with casting needs Our years of experience and profound knowledge of the industry has positioned us as a trusted partner for businesses seeking top-notch casting equipment and support In all our years we've always been dedicated to continuous improvement and client satisfaction which has driven us to change and evolve to the ever-changing marketplace