×

×

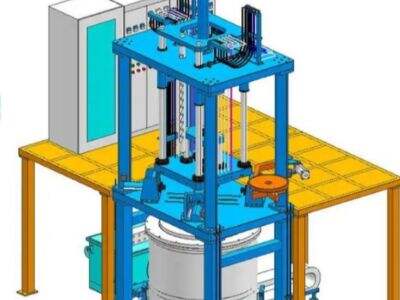

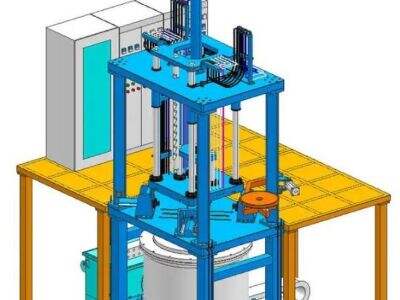

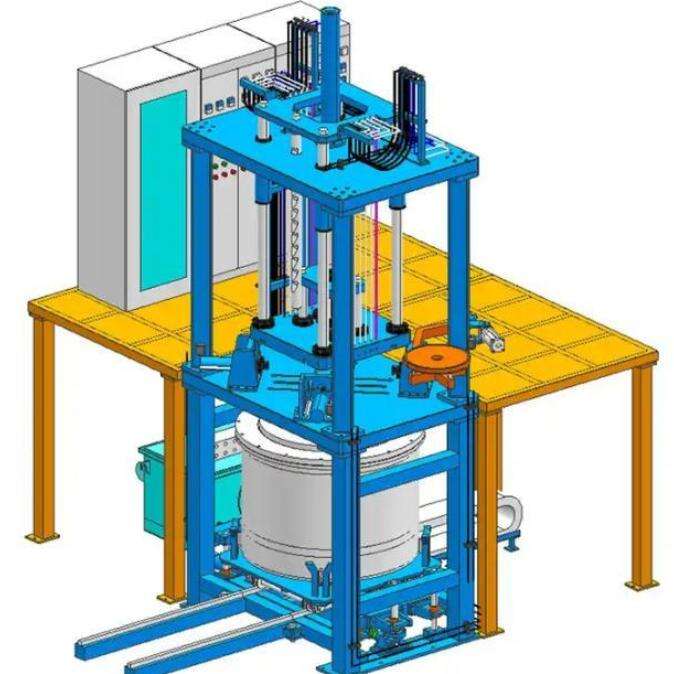

Rotational casting machines are transforming the way aluminum parts are made. These machines rotate molds very slowly while molten aluminum is poured into them. This rotation evenly distributes the metal, so that hollow forms have countryside-swept w...

VIEW MORE

Sustainable manufacturing is booming fast because people want to make stuff in ways that don’t bode destruction for the planet. One way to accomplish this is by employing rotational casting machines to create aluminum components. Aluminum is relative...

VIEW MORE

Big aluminum cans housings Big-diameter aluminum housings are key parts for many fail machines and instruments. Manufacturing these large parts is hard, because aluminum is strong but has to be light and in just the right shape. At Boqiao, we have de...

VIEW MORE

Aluminum is difficult and expensive to work with on a large scale, but rotational casting machines can make it much easier and cheaper. These machines are used to form aluminum by slowly rotating a mold while filled with molten metal that coats the i...

VIEW MORE

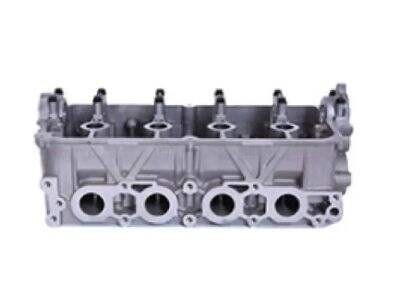

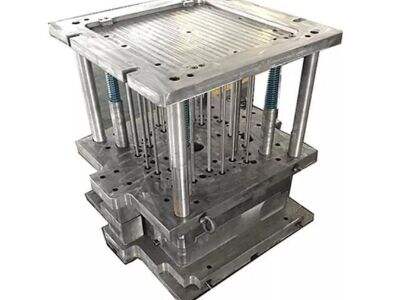

Low pressure die casting is a special process for making items, like car and truck engine parts out of metal. This process is crucial to create high quality parts with less material. At Boqiao, our attention is on delivering materials that are strong...

VIEW MORE

Parts made of aluminum can warp or bend after being heated and cooled too quickly. That problem, known as distortion, renders the parts less useful or even unusable in machines. Boqiao has discovered ways to aid in this effort by employing a unique p...

VIEW MORE

In car making, speed and correctness of parts is very important. There are numerous ways to reach this goal, and one of such is gravity casting. This is wherein liquid metal is poured into a cast with the shape of the molded part. Automation of ...

VIEW MORE

Energy use is a substantial part of how aluminum becomes stronger and excited to do various kinds of jobs. This material can be altered by the process of heat treatment, which involves carefully heating and cooling the metal. This process requires a ...

VIEW MORE

If the aluminum alloy is required to be strong and reliable product, it will certainly require that same hardness of its surface remains. This is where sealed quench furnaces enter in. These special furnaces regulate the heat and cooling of aluminum ...

VIEW MORE

When aluminum parts must be made stronger or more durable, hardening is often the process of choice. But in the course of doing so, aluminum can readily react with oxygen from the air and create a problem known as oxidation. Oxidation makes for a rou...

VIEW MORE

At Boqiao, we allow for the engine blocks to be made better with a little something called low pressure die casting. This is a process that makes the aluminum stronger and last longer. The process involves pressing hot aluminum into a mold using low ...

VIEW MORE

Low pressure die casting is a process that involves injecting melted metal into a cast very slowly. It can help produce strong, lightweight parts. But to ensure these parts emerge crack- and-hole-free, clever monitoring systems are extremely useful. ...

VIEW MORE