×

×

Did you know that dies are important equipment used in the production and manufacturing of a wide range of items? They are used to cut, trim and shape materials such as metals, plastics or paper; in many different sizes. It makes these factories and other industries that engage in manufacture highly relevant. However, how are they made? This time we will discuss the process of making these useful tools by a professional top die maker.

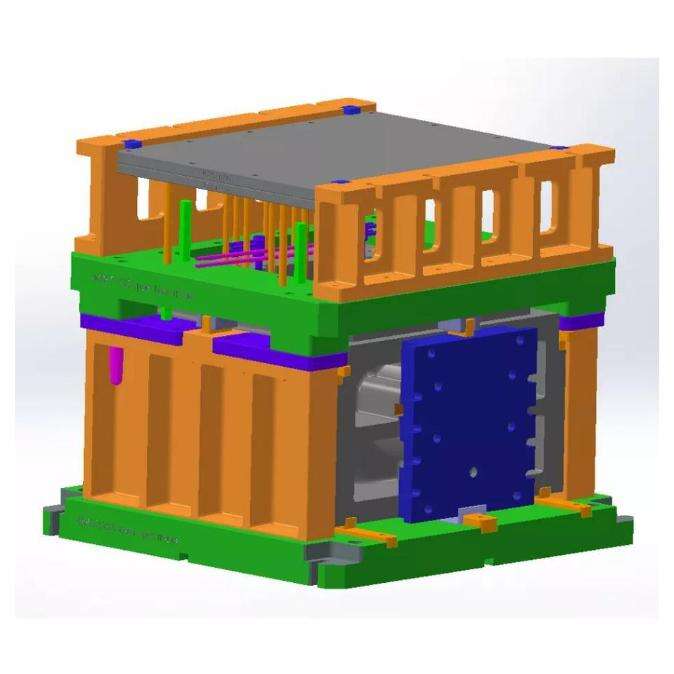

After you have created the design of a die, the next step is to make it. Die designing—Engineers drawing 3D Models of them through their Computers Based on that Professional. The next stage is when the engineers will use some computer applications to draw a plan on how they will make our die. One major thing with them is that these drawings are made for a particular reason which helps them see if it’s correct or not. If necessary, they can study the design in detail and make corrections before building it. When they have finished designing and approved this, then test panel die cut follows suit. By employing the latest technology known as 3D printing. The way the Boqiao die casting manufacturer has designed its casting moulds for testing purposes may expose other potential problem zones where some dimensions might also be affected by these gaps in the alloy structure of such materials.

After finalizing the design and testing its quality, we are now able to manufacture those dies using a variety of ways. Employing a CNC machine is just one of many methods that make a die. It happens with its computer-programmed cutter system which cuts material into shape as per given coordinates. In addition, it is very accurate enabling it to develop very delicate and fine cuts. Another way of making a die would be on wire EDM machine. With this problem, there exists an electrical wire that is also tiny enough for such precise cutting. This means that the dies will be made correctly and meet all the required standards.

They then choose the appropriate die material at this stage. This step is critical since the material must be strong enough for its intended use. Moreover, Boqiao die manufacturer also considers how their surface’s looks like before they can start producing them in mass amounts. If while being embossed, their aluminum surfaces possess some open pores, these little closed regions turn into open ones; therefore, allowing small bubbles of air to form right on top of a label thereon somewhere else again. Without having acceptable surface finish levels, the life span of this particular die would have been so short compared to others

Such tests come after the die is made, to ensure that it is working well. This includes weighing, measuring and examining lines to make sure they are correct. They can also test this against different materials so as to tell if it will break or become damaged when subjected to the most likely jobs for the model. These measures are vital for ensuring that all required standards are met.

Some of us have been in this business for a long time; we know what we are doing. Within our team, there are capable engineers and workers who are best at their work. Our advantage lies in making definitely good dies. When manufacturing, we always employ materials of highest quality and tools which move forward by decades on innovation scale – this ensures our dies would stay straight for years. We focused on quality so that these all could be sent correctly according to customer’s needs on record as perfect being delivered within.”

We not only want to create a good product, but also offer our customers the highest quality service. Boqiao die manufacturers have been on the market for several years and engage closely with their customers to translate their own desires into reality from project initiation to completion. We update our clients regularly about how far we have gone with their paper, as well as addressing any issues they might have raised. This communications goes a long way into creating trust and enhancing a positive experience for all involved parties.

Our Dies manufacturer in the field of casting began in 1979, with the sales of casting materials, laying a strong foundation for our expertise and market presence. We've built long-lasting relationships with our clients over the years by offering high-quality products, and offering exceptional customer service. In 1997, we expanded to include the production of industrial electric heaters. This strategic move enabled us to provide more complete solutions for our customers, which met their increasing demand for reliable and efficient heating equipment. In this phase, our commitment to quality and innovative thinking made us stand out from the competitors. In 2002, we'd diversified our offerings by introducing the production of casting equipment. We could offer an array of options to casting, encompassing materials as well as machinery. This enabled us to serve as a one-stop store for our customers' casting needs. We have earned the reputation of a reliable business partner due to our vast experience and knowledge in the casting business. In all our years we've been committed to continual improvement and customer satisfaction, which drives us to adapt and grow in an ever-changing market.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Dies manufacturer customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

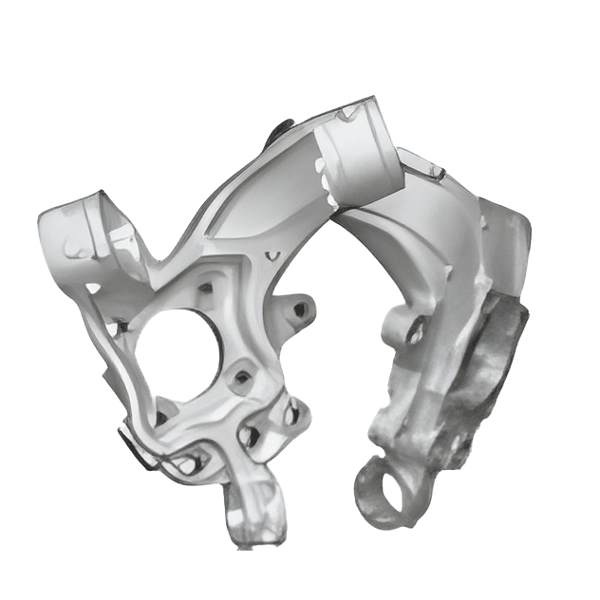

BoQiao's gravity-casting machine Dies manufacturer small dimensions, which makes it a good choice for many manufacturing settings. The BoQiao gravity cast machine's compact design and top-quality performance make it an ideal option for a variety of manufacturing settings. Its low cost and long-lasting capabilities make it an excellent investment for companies looking for solid casting solutions. The machine is highly regarded by its customers due to its constant high-quality, simple operation and maintenance and increased efficiency.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, Dies manufacturer manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We are able to provide customers with all kinds of overall solutions and turnkey projects including technical consultation, equipment selection, mold manufacturing and process development, operation training and so on. Let our products add the value our customers need. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.