×

×

Housing casting is the chief process of producing and creating some long-lasting products that we use in our home as well as many other places. Process of manufacturing these items is quite a long list but housing casting takes the lead when all other process are concerned. So in this article, we understand what is housing Boqiao Aluminum casting parts and the working procedure of it step by steps.

Casting of housing — filling the mold with molten liquid metal or plastic. The use of the mold is to produce some other part or product. Materials such as sand, wax or silicone — which is a pliable and bouncy material for molds. Then, the mold is placed in a corner where it can harden (although not entirely) over time. After it has completely turned solid we take off the mold and voila, we see what all our efforts have prepared in front of ourselves!

Let us go through a few pros and cons of different ways you can cast housing. Methods that are often used include sand casting, die casting and investment casting. Each of these methods allow us to produce different types of products, so depending on what we are trying to make this is the way in which we choose our method. Sand casting, for instance is better to use when creating large and simple types of shapes whereas die-casting can be more cost-effective if small or detailed components need manufacturing.

We will first outline the product that we wish to make. We are starting in on our housing casting process. This is a critical first step to how we envision shaping the product both in terms of layout (design) and functionally. Either by drawing our design on paper with pencil, or using special programs like Computer-Aided Design (CAD) software. After we are done with the design and make sure it is perfect, next step is to create a mold properly using rituals materials with Boqiao Gravity die casting machines.

In order to form the mold, we will use a block of material (such as sand or wax), and carefully carve it until it fits our configuration. This Boqiao Low Pressure die cast machines is the shaping part of it all, big picture thinking which ultimately will decide how what we make finally looks like. Once we have our mold, it is filled with liquid hot metal or plastic. The hot material is poured into the mold are cooled down to solidify. Once it completely cools and hardens, we remove the mold — and now our product is ready for use!

Steel Housing casting is better than different processes of constructing products Fabrication. This is where 3D printing really shines, because it lets us fabricate complex shapes and designs that would be notably difficult — or impossible — to achieve by another process. That means, we can offer unique and exciting products. Housing casting can be made on a large circuit is its low cost, this is the second major reason why housing castings are becoming increasingly popular. It also allows us to create a huge range of products with low unit costs which means that we can afford to make large quantities quickly and economically.

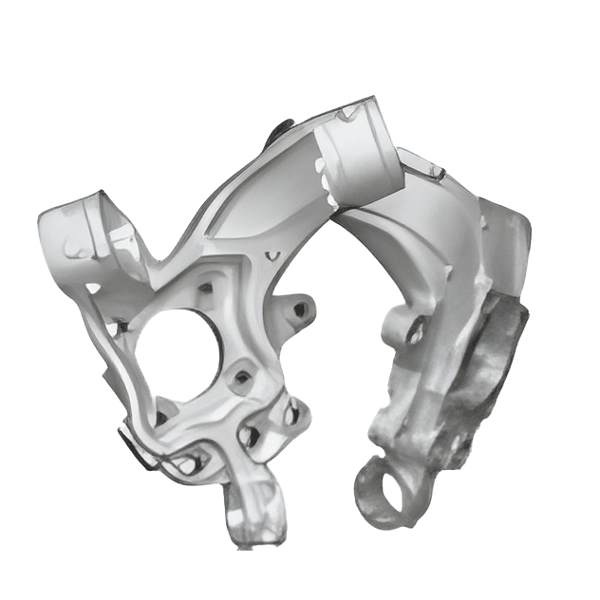

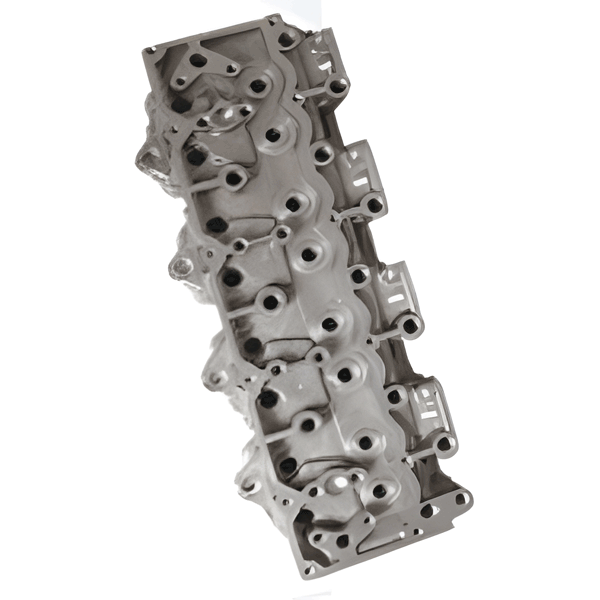

Housing casting is used across many industries and, indeed all types of products we come in contact with everyday. For example, it is widely used for the creation of parts that go in vehicles to include cars and trucks as well as machinery found on factory floors. Besides, we all know that housing casting is frequently employed in manufacturing these mundane products which can be found right at our homes everyday such as kitchen appliances and instruments. It is also found in stylish things like jewelry, desks and other attempted pieces that people admire.

Our company has sold and made over Housing casting units since 1999. Excellent service and reliable quality make our company have a good reputation with its customers. The company has sold its products to Southeast Asia and Africa South America as well as the Middle East. Customers have also been satisfied with the service and quality. Customers should be encouraged to create more value.

BoQiao's gravity-casting machine features small dimensions, which makes it a great choice for a variety of Housing casting. The BoQiao gravity cast machine's compact design and high-performance make it an ideal choice for various manufacturing environments. Its reliability and value make it a valuable investment for companies looking for reliable casting solutions. It is praised by clients for its consistency in quality, easy operation and maintenance and increased productivity.

Our Housing casting in the field of casting began in 1979, with the sales of casting materials, laying a strong foundation for our expertise and market presence. We've built long-lasting relationships with our clients over the years by offering high-quality products, and offering exceptional customer service. In 1997, we expanded to include the production of industrial electric heaters. This strategic move enabled us to provide more complete solutions for our customers, which met their increasing demand for reliable and efficient heating equipment. In this phase, our commitment to quality and innovative thinking made us stand out from the competitors. In 2002, we'd diversified our offerings by introducing the production of casting equipment. We could offer an array of options to casting, encompassing materials as well as machinery. This enabled us to serve as a one-stop store for our customers' casting needs. We have earned the reputation of a reliable business partner due to our vast experience and knowledge in the casting business. In all our years we've been committed to continual improvement and customer satisfaction, which drives us to adapt and grow in an ever-changing market.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, Housing casting manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We are able to provide customers with all kinds of overall solutions and turnkey projects including technical consultation, equipment selection, mold manufacturing and process development, operation training and so on. Let our products add the value our customers need. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.