×

×

An Inductotherm furnace is one such special kind of machine that can heat metal to extremely high temperatures until it gets melted completely. These are used in many industries to make various products play with metal like cars, airlines and so on[]. Read on to study more about this cool device, how it works and why Inductotherm furnaces are the best for metal casting in present time

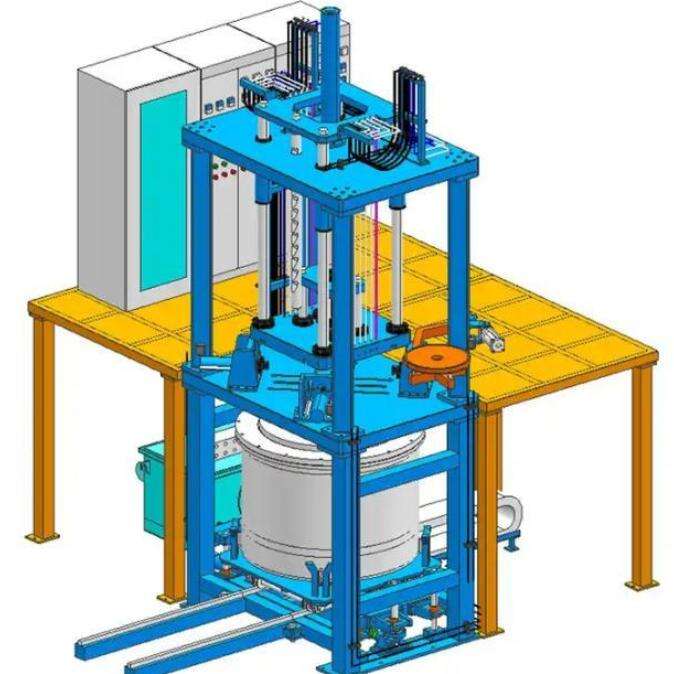

This Boqiao Gravity die casting machines is the world-class Inductotherm furnace that heats metal through electromagnetic waves. It is called induction heating. There is a copper coil inside the furnace. This coil produces an electric field, which is key in the heating process. These electromagnetic waves heat the metal, when we put them in to our furnace and they make fastest movements of those tiny particles called molecules on metals. It's like if you rub your hands together very quickly, how they become warm; however this large scale and on a hotter side!

The heat generated in a Inductotherm furnace is high powered, enabling the metal to reach its melting temperature rapidly. So this allows the metal to be shaped fast into different shapes as compared with other conventional processes. This Boqiao Low Pressure die cast machines capability is what separates the Inductotherm furnace from many other types of furnaces, as it has an unparalleled ability to heat any metal at such high efficiency levels

Inductotherm furnaces are manufactured in numerous shapes and sizes to cater for the requirements of various industries. Others are small and melt bits of metal in factories called foundries. These small furnaces are ideal for the production of small metal products. In comparison to these are the large Inductotherm furnaces which can heat up 100 tons of metal in one go. The largest Inductotherm furnace ever put in operation is rated at a whopping capacity of 600 tons! That is why this is the best metal melting machine for big projects, where they require a lot of metals to reach their melting temp at once.

These furnaces come in different sizes and can therefore be used for various applications. They can be found in small workshops or used for industrial plants. On a large scale, Boqiao BQ melting furnace each furnace is useful in different processes of metal production.

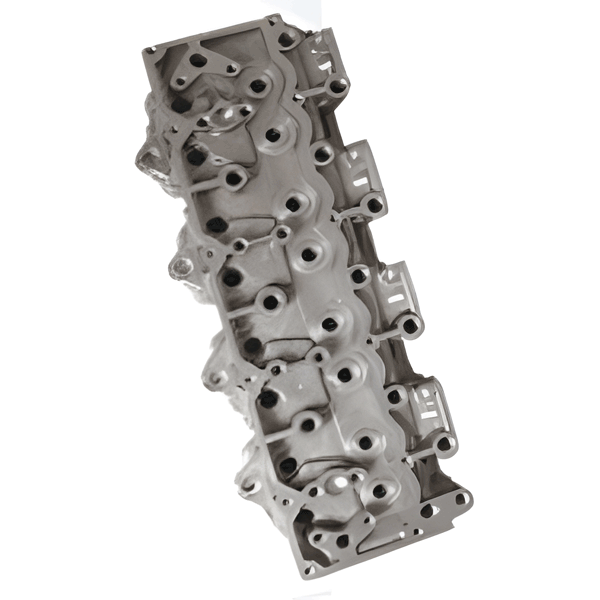

Processing materials using that thing, the future of creating all things metal is definitely looking up. The shaping of metal into different forms is a process known as Metal casting, and it impacts various industries ( including automotive(cars), aerospace(airplanes), medical equipment). In terms of melting, the Inductotherm furnace is far more efficient at metal smelting than any downstream competitive methods over any other systems. It is this BQ quenching furnace speed and efficiency that makes it a great asset for businesses in these sectors.

Maybe in the future, we will get to see more great application for Inductotherm furnace. That could be useful in, for instance, building new types of devices that produce energy from renewable sources. Space exploration, Aluminum casting parts similarly to all the above mentioned fields may also find this technology useful for creating some supplemental (or even life-saving) parts and tools on demand during missions outside our atmosphere.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, Inductotherm furnace and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include the technical support, selection of equipment and manufacturing processes, design, training and operations. Our products can create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our Inductotherm furnace has sold and manufactured over 2, 000 units from 1999. Reliable quality and excellent service make our company enjoy a great reputation among customers. In addition to sales in every city and province across the country Our products have also been offered to Southeast Asia, Africa South America, Middle East and other regions, and have been a great success by customers. Based on the premise of win-win and cooperation, sincerity and honesty, BoQiao will continue to pursue the path of professional development and continuously improve products and services to better meet the demands of customers. The need to assist customers in creating more value.

The BoQiao Inductotherm furnace is designed with a compact structure which makes it a great option for various manufacturing environments. Its top-quality performance guarantees efficient and precise casting, and its user-friendly interface makes the process of production, allowing users to get the best results with little training. This multifaceted machine is widely utilized across multiple sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its low cost and long-lasting capabilities make it an excellent choice for companies that are looking for solid casting solutions. Customers appreciate the machine's consistent quality and the convenience of its operation and maintenance that reduces downtime and enhances productivity.

In Inductotherm furnace, we began our journey in the field of cast iron through the selling of casting components. This was the beginning of our knowledge and presence on the market. Through the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service. In 1997, we widened our business to include manufacturing of industrial electric furnaces. This strategic move enabled us to provide more comprehensive solutions to our customers and meet their growing demand for reliable, efficient heating equipment. Our commitment to innovation as well as the highest quality in this period was a distinct feature from the rest of the competition landscape. By 2002, we further expanded our product range by joining the casting equipment manufacturing sector. This expanded our capabilities to provide a comprehensive array of casting options, from machinery to materials making sure that our customers could count on us for all their casting requirements. Our vast experience and comprehensive understanding of the industry have positioned us as a trusted company for companies looking for top-quality casting equipment and services. Through our long history, we have remained dedicated to continual improvement and customer satisfaction, which has driven us to adapt and grow to a changing marketplace.