×

×

Many of the machines we use each day are made using machine castings. It may not be readily apparent, but these part-castings play a vital role in enabling everything to perform efficiently. These casting: It becomes machine castings It requires pouring the metal — drained liquid from a melting process— in hot condition into an enclosure of suitable shape. The level of hardness attained by the cooling liquid metal. Once the metal is fully cooled (it has to be completely cool), it can be removed from that mold and this will now represent a machine casting.

Next, we will cover some of the benefits that machine castings can offer you when it comes to making machines. One of the main connected with machine castings is power. That is why they can build machines which will carry a lot of weight, and have enough resilience. What makes Boqiao machine casting so fantastic is that because they can be in nearly any form and shape, this in turn means that manufacturers have the flexibility to enable machines with high detail and sensitivity (high resolution), a necessary characteristic for correct machine function.

Machine Castings largely needs lot of skill and expatriation. The process starts with the creation of a mold. The mold needs to be produced with important carefulness and properly formed in order data the mold accurately. Once the mold is prepared, the hot metal into a fluid state is poured in. Many skills are needed to accomplish this so that the metal flows properly into the mold. The last step in the process is to dude a solidify and chill down preceding mounting Furthermore, cooling the alloy about x-y% with respect to plasticity is quite painful, because you must ensure that it cools evenly in order for it not to split or break.

The casting of machines has very important considerations for manufacturing a machine. These are employed to manufacture a variety of devices such as engines, turbines and other machinery. Machine castings are beneficial because they provide strength and reliability which is a guarantee that the Boqiao casting machine on ground will work perfectly. Machine casting has reached milestones and changed the course of history – every machine that exists today, some way or another includes a variety of castings in its configuration-machinery without which our lives wouldn't exist as we know them.

Successful Practice: The complete range in castings will allow you to enter into different vertical markets like Mining, Fertilizers and more concatenating further the same point; Wide product mix is necessary" meaning – If u are a machinery manufacturing company 'HIGH CLASS' casting is very imp; for spoilt material quality results your machine as attested. For example, creating awareness among queue at work place employment. The best investment castings are made from the highest quality materials by highly trained and skilled workers that know what they're doing. With these top class castings, your machines can perform superior and ultimate longer. For any manufacturer, this is a wise deviation route to ensure the survival of their machines.

Good quality castings also improve the performance on your machines to a great extent. It is also appreciated for making high end castings with note-to be the best size because help in providing exact fitting to machine as well allow it accurate and work flawlessly. Boqiao die cast machines provide the best performance which in turn can save you a lot of banners and time spent re running ads. In those ways, when they function properly like that on this autolaunchmechanism.com you get help in doing things faster and more efficiently.

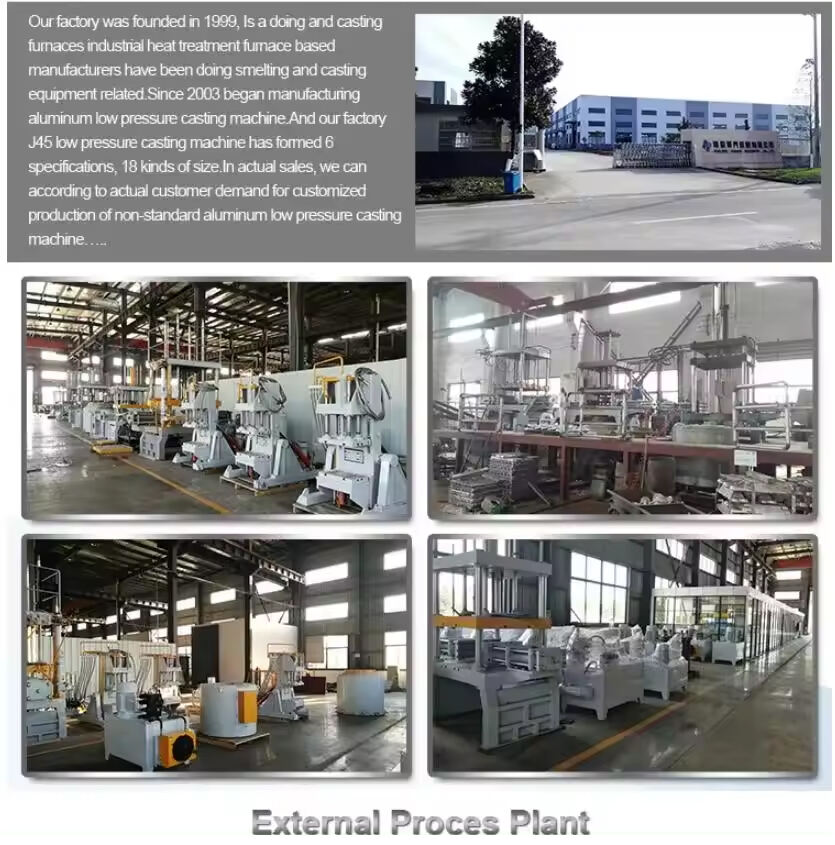

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, Machine castings and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include the technical support, selection of equipment and manufacturing processes, design, training and operations. Our products can create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our journey in the field of casting started in 1979 with sale of casting materials and laying the foundation to our industry expertise and market presence Over the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service In 1997 we widened our operations to include the manufacturing of industrial electric furnaces This strategic move allowed us to provide more complete solutions to our customers meeting their growing demands for efficient and reliable heating equipment Our dedication to innovation and quality during this time made us stand out from the rest of the competition landscape By 2002 we expanded our product range by moving into the manufacturing of casting equipment sector This expanded our capabilities to offer a wide range of casting solutions from materials to machinery making sure that our customers could count on us for every aspect of casting We're a trusted business partner due to our extensive experience and knowledge in the Machine castings Since our beginning we have remained dedicated to continuous improvement and customer satisfaction which has driven us to evolve and adapt in an ever-changing market

BoQiao's Gravity Casting Machine has a compact design, which makes it a good choice for many manufacturing settings. Its superior performance ensures efficient and precise casting, and its user-friendly interface makes the production process, allowing operators to achieve optimal results with little training. This multifaceted machine is widely used in a variety of industries, including motorcycle components auto parts, auto parts, Machine castings, and engineering machinery. The durability and affordability make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by its customers due to its constant quality, ease of operating and maintenance, and the increased efficiency.

Our Machine castings has sold and manufactured over 2, 000 units from 1999. Reliable quality and excellent service make our company enjoy a great reputation among customers. In addition to sales in every city and province across the country Our products have also been offered to Southeast Asia, Africa South America, Middle East and other regions, and have been a great success by customers. Based on the premise of win-win and cooperation, sincerity and honesty, BoQiao will continue to pursue the path of professional development and continuously improve products and services to better meet the demands of customers. The need to assist customers in creating more value.