×

×

Have you ever thought that how do people make those wonderful metal objects which use to be a sword or Jeweler item? It all starts with a process called melting metal Unlike most other metal turnkey plant builder, Boqiao we own are melting forge is a solid custom not liquid indeed. Visualize the Kiln to be like a mega oven. So like a melting forge, only above it all. Boqiao Gravity die casting machines Melting it down to a warm viscous pool, which our artist can fashion into anything they want. This is the first step in amazing metal art pieces

No matter if we want to make the next sexy new thing, it has an origin in there as raw metal. Raw metal is the unprocessed, form of a material generally referred to as ore iron ore or copper before it has been fabricated into anything else. These are raw materials directly come from the Earth, like bricks for your projects. We get this raw mettle red hot and turn it into a liquid. This is where the magic really starts! A metal on liquid form can be molded into any kind of shape and design. This Boqiao Low Pressure die cast machines is the point where creativity—whether it be in a dainty bauble or death weapon begins to take shape.

One of the things that we really like it to produce blades for swords, at Boqiao. The sword needs to have the steel melted in a forge. Steel is a category of metal made primarily from iron mixed with carbon. When the wax starts to melt, it gets very fluid and pourable so we can simply cast that into a mold where you have got like blade shape. Then we prepare the blade in a special way to be very thin and extremely sharp at this point. That is A and let me tell you this, because sharpening up the sword as in good blade deserves it's very necessary step right? This Aluminum casting parts is the final handmade sword when melting forge Anonymous swords was gold wow its not only a weapon, it's Art.

This is why it took months of labor and skill for the melting forge. You first have to choose what metal you want melted down for whatever project. This is due to because each type of metal has its properties when we heat and bend it, so that will definitely affect what form our job wants. Certain metals also melt sooner or will maintain a higher signal better as they are cooling. Was also how we heat the metal It matters for breaking Our plan to resist fall through When hot when it should not. Not to the point of super hot, we want our tile not expending like ice or a frozen rubber band and so cannot make use of this wire either. Once the metal is melted, we have to pour it into whatever shape that we require as quickly as possible before the material cools and becomes solid once again.

The forge is the melting that creates space for art to be created. Melted metal can be formed in many ways, allowing us to create things that are harder or impossible with other means. And this is like for example fancy jewelry that can be as detailed and accurate it cannot get. They will draw patterns and designs that you would want to have them on your body as well. We do also custom work for people that want something even more unique.

Our journey into the field of casting began in 1979 with sales of casting materials that laid the groundwork for our experience as well as our market position Over the years we have built lasting relationships with our clients through offering high-quality products and excellent service In 1997 we expanded our services to include manufacturing of electric furnaces for industrial use This move was a strategic one that allowed us to offer more complete solutions for our clients and satisfy their increasing demand for high-quality reliable heating equipment At this point our commitment to quality and innovative thinking made us stand out from the competition In Melting forge we had further expanded into the manufacture of casting machines We were able to provide the full spectrum of solutions for casting including the materials as well as machinery This enabled us to become a one-stop store for our customers with casting needs Our experience and extensive knowledge of the industry has made us a reliable partner for businesses seeking top-notch casting equipment and services We've always been devoted to customer satisfaction and continuous advancement This has driven us to evolve and adapt in a marketplace that is ever-changing

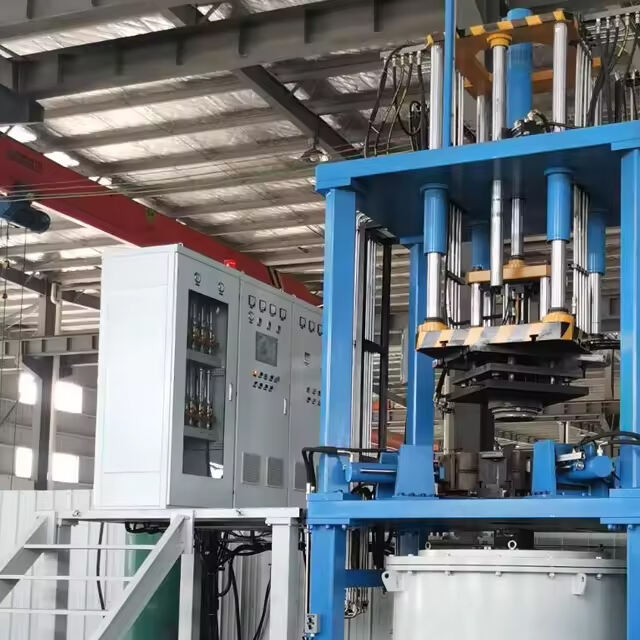

Melting forge gravity cast machine is a compact design, which is a perfect fit to use in a variety of manufacturing settings. Its high-performance makes for an efficient and precise casting while its user-friendly system simplifies the production process, allowing users to get the best outcomes with only minimal training. This multifaceted machine is widely employed in various industries, including motorcycle components automobile parts electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by customers for its dependable quality, simplicity of operation and maintenance, as well as its improved efficiency.

Since 1999 the company has produced and sold more than 2, 000 units. BoQiao has Melting forge a good reputation with customers because of our reliable quality and excellent customer service. Apart from sales in all cities and provinces across the nation Our products have also been sold to Southeast Asia, Africa South America, Middle East and many other locations, and have been a great success by customers. Based on the business ethos of cooperation and win-win, integrity and honesty, BoQiao will continue to follow the path of professional growth and continually improve its products and services to better meet the demands of customers. Customers must be helped to create more value.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, Melting forge and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include the technical support, selection of equipment and manufacturing processes, design, training and operations. Our products can create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.