×

×

Hhow do the engineers make it so precise? One of the special technological processes that can help them here is mold casting. Mold casting: This is the process by which Engineers create a mold, form or shape of an item they want to produce. Once the mold is prepared, they fill it with molten metal or plastic. Like this they are able to create an ideal replication of the item which has been made by all of them. The great thing about Boqiao Gravity die casting machines is that engineers can make things very precisely, so the items they make exactly mimic their original design.

To do Boqiao mold casting is not easy, it requires creativity and science. Engineers must immerse themselves in creativity and imagination part of their brain to find the perfect mold for whatever it is they need. That means considering the aesthetics and functionality of a mould. They also need to understand a lot about the materials and what different material will do when heated up until they melt. It takes a fair amount of time, patience and skill to make a good quality mold. Because, it is just not something that can be done fast.

Mold Casting: There are lots of molds which is use in mold casting, but mostly type save sand casting or investment. Sand Casting A mold is made using sand in the process of sand casting. First, they mold the sand to what they want it shaped like, then pour hot molten metal into the casting. Hot metal is poured into the mold, then cooled to a solid object. Investment casting is a little complex, on the other flip side. First, engineers develop an item model using wax for this method. For the wax model, they put a specifically kind of plaster over it. Another method is to pour plaster around the wax model and when its harden you heat it up, thus melting all the wax. This creates a perfect Low Pressure die cast machines mold that can be filled with the molten metal.

This largely transformed how things are manufactured by mold casting. Prior to the development of this process, engineers had a hard time creating replicas. It involved a lot of manuel work, such as moulding metals or plastics by hand which is time consuming and in most cases hard. After Boqiao mold casting was invented, it allowed people to create reproductions of items quickly, and with accuracy. That way, engineers can mass produce items and keep the business making lots of goods that more people will be able to buy in turn.

Mold casting is quick and enables engineers to make impressive shapes/designs. The things they can produce would be incredibly time-consuming or even impossible to craft by hand. For instance, they are able to fabricate objects with complex patterns or structures that bend in different directions. Achieving all of this design complexity and without compromise has opened new doors for engineers in terms of innovative part concepts, thanks to the power of BQ melting furnace. They could come up with any shape they wanted, which would make their items look nicer as well as more useful.

Since 1999 we have manufactured and sold over 2000 units. Mold casting has earned a good reputation among customers due to our reliability and quality as well as excellent customer service. In addition to sales in all cities across the country Our products have also been shipped to Southeast Asia, Africa South America, Middle East and many other locations and are well-received by customers. Based on the business ethos of cooperation and win-win, sincerity and integrity, BoQiao will continue to pursue the path of professional development and continuously improve products and services that better suit the needs of its customers. Need to help customers create greater value.

Our Mold casting in the field of casting began in 1979, with the sales of casting materials, laying a strong foundation for our expertise and market presence. We've built long-lasting relationships with our clients over the years by offering high-quality products, and offering exceptional customer service. In 1997, we expanded to include the production of industrial electric heaters. This strategic move enabled us to provide more complete solutions for our customers, which met their increasing demand for reliable and efficient heating equipment. In this phase, our commitment to quality and innovative thinking made us stand out from the competitors. In 2002, we'd diversified our offerings by introducing the production of casting equipment. We could offer an array of options to casting, encompassing materials as well as machinery. This enabled us to serve as a one-stop store for our customers' casting needs. We have earned the reputation of a reliable business partner due to our vast experience and knowledge in the casting business. In all our years we've been committed to continual improvement and customer satisfaction, which drives us to adapt and grow in an ever-changing market.

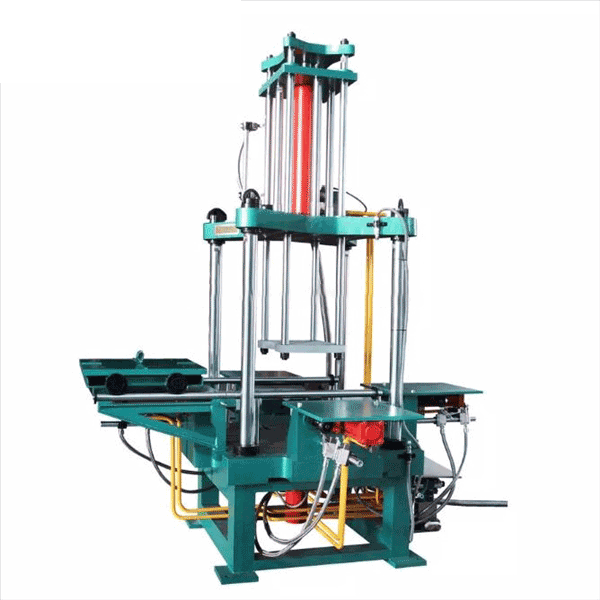

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a wide range of Mold casting that include technical consultation, equipment selection and manufacturing and process design, as well as training, and operation. Let our products add value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

BoQiao's gravity cast machine is a compact design, which makes it a good choice for a range of manufacturing settings. The Mold casting of the machine ensures accurate and efficient casting while its user-friendly system simplifies the production process, which allows users to get the best outcomes with only minimal training. This multi-purpose machine is used in a variety of industries, such as motorcycle parts automobile parts and electric power fittings as well as engineering equipment. The durability and affordability are a great investment for businesses seeking solid casting solutions. The machine is highly regarded by customers for its consistent high-quality, simple operating and maintenance, and the increased production.