×

×

Once upon a time there was this amazing metal called aluminum. It is a very lightweight and strong metal which made of aluminum. You can find it all around us — in cans and even planes! But molding the aluminum into other shapes proved difficult. That, Boqiao Gravity die casting machines was until the neat little trick of sand cast aluminum

It is a kind of special casting method to produce products from aluminum, which are sand castings. The description construct is simply known as "sand cast. Here the hot liquid Al is poured into a sand mold. This mold is identical to the final shape that we want for our finish product. And once the molten aluminum colds, it solid and becomes a very durable product that will last for years or even forever!

The advantage of playing with sillty aluminum sand is that it becomes a lot easier to design. Sand molds can easily be formed into any size or shape that a designer might dream up. By doing this, Boqiao Low Pressure die cast machines it would allow people to make extremely intricate and detail designs that would be almost impossible if done through other means. From a small ink-blot to complex design — in sand (aluminum) it will set you right!

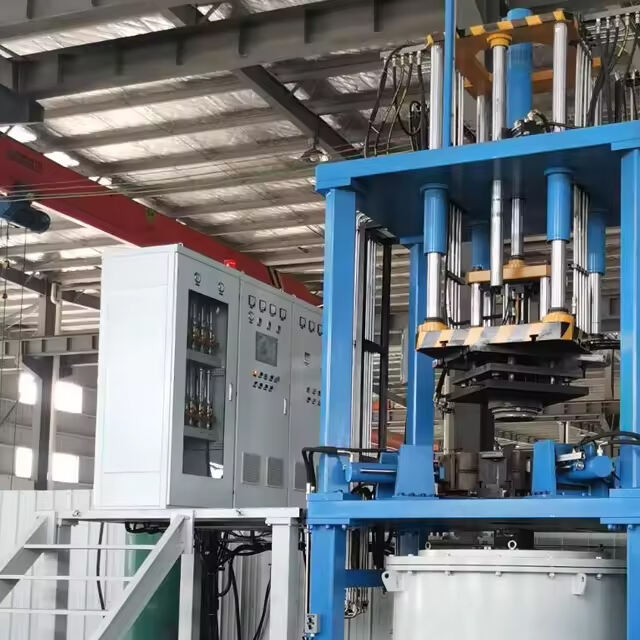

Advantages of Sand Cast Aluminum Intead of that, this is strong as hell and lasts a long time. Because this strength that makes it so oft used for things like airplanes and cars circuits A great advantage of sand cast aluminum is that it's extremely lightweight. It is easy to carry and handle. But best of all, sand cast aluminum does not rust or corrode very easily. This Boqiao BQ melting furnace makes it ideal for things used outdoors, so you do not have to concern yourself with them falling apart over time.

Making some parts of machines was a real problem before the invention of sand cast aluminum. This BQ quenching furnace forced manufacturers to waste time and money trying new ways of producing the parts they required. A few of the methods were more time-consuming and expensive. Sand cast aluminum transformed the world! This new technique made the production of items for different industries very much faster and simpler. It really did change the manner in which stuff was produced, making factory operations more effective.

One more great benefit of sand cast aluminum is that it benefits the planet. SInce it is very strong, you do not have to replace the concrete as a often as other materials. This results in less waste being produced, great for the environment. Furthermore, it is 100% recyclable sand-cast aluminum. In fact, Aluminum casting parts when products made with it reach the end of their life they can be melted down and then used to make new stuff without giving up any of that great material benefit which aluminum provides.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various Sand cast aluminum, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer customers all kinds of overall solutions and turnkey project services, such as technical consultation, equipment selection, mold manufacturing design, process development as well as operation training and much more. We are confident that our products will create value to our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

The BoQiao Sand cast aluminum is designed with a compact structure which makes it a great option for various manufacturing environments. Its top-quality performance guarantees efficient and precise casting, and its user-friendly interface makes the process of production, allowing users to get the best results with little training. This multifaceted machine is widely utilized across multiple sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its low cost and long-lasting capabilities make it an excellent choice for companies that are looking for solid casting solutions. Customers appreciate the machine's consistent quality and the convenience of its operation and maintenance that reduces downtime and enhances productivity.

Our journey in the field of casting started in 1979 with sale of casting materials and laying the foundation to our industry expertise and market presence Over the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service In 1997 we widened our operations to include the manufacturing of industrial electric furnaces This strategic move allowed us to provide more complete solutions to our customers meeting their growing demands for efficient and reliable heating equipment Our dedication to innovation and quality during this time made us stand out from the rest of the competition landscape By 2002 we expanded our product range by moving into the manufacturing of casting equipment sector This expanded our capabilities to offer a wide range of casting solutions from materials to machinery making sure that our customers could count on us for every aspect of casting We're a trusted business partner due to our extensive experience and knowledge in the casting industry Since our beginning we have remained dedicated to continuous improvement and customer satisfaction which has driven us to evolve and adapt in an Sand cast aluminum market

Our company has sold and made over Sand cast aluminum units since 1999. Excellent service and reliable quality make our company have a good reputation with its customers. The company has sold its products to Southeast Asia and Africa South America as well as the Middle East. Customers have also been satisfied with the service and quality. Customers should be encouraged to create more value.