×

×

Casting instruments make able to produce for us many different items: toys, pots and jewelry. That is a huge part of making stuff we can use and enjoy. When you are just starting your journey in casting, one of the most important things that you can do is to learn how to use a proper set of instruments while doing so. Given a bit of practice and some patience, you can create lovely, unique items that will be perfect to show off to your friends

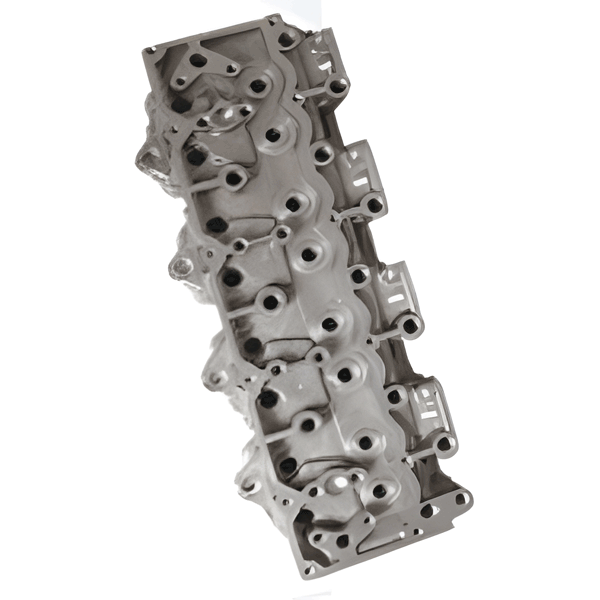

It is a few important tools what are required to start out casting instruments. The first and foremost the tool you require is a mold. These Boqiao Aluminum casting parts molds, which can be of different shapes and sizes are created in materials like silicone or metal. This means that the mold is important if you want to make the object, it forms what your making. You can think of it as a vessel—a tool that guides the material into becoming whatever form you want.

The casting material is one more essential you will require. This material can vary, and may be plaster, resin or metal. What kind of casting material to use for making what. If you are making a toy, for instance, then it might be useful to opt for silicone (nice and bendy) instead. On the other hand, if you are making a jewelry piece then maybe you would stick with metal in order to make whatever it is LAST

We think the following 5 tips will make your use of casting tools that much easier and more successful. The number one thing you can do to avoid over exerting yourself is ensuring that you prepared the right amount of casting material. Using too little material may leave your object weak and brittle; using too much can cause over-extrusion. However, if you overdo the amount of material to be used in the object for Boqiao Gravity die casting machines could end up too heavy or too big which may give a adverse result.

Tip 3: Read the Casting Material Instructions Most casting materials come with a set of instructions to follow, and being thorough in how you use them is crucial. Mix dry times vary from material to material, so please follow these for best results. Boqiao Low Pressure die cast machines will benefit you, in the long run, if you take time to learn how each of them works before getting started.

Selecting an appropriate casting instrument for your project is a crucial part of the overall casting procedure. The next thing you should consider is the material type that will be used Various other casting tools designed for different types of materials. Something like if you want to cast metal, then that will make use of an instrument designed for a different type of material than that used in casting silicone.

One more excellent trick is typically a discharge professional. The release agent is a type of spray or liquid that you use to coat the mold before pouring in casting material. This allows the material to quickly release from the mold when dry. This allows the part to not stick in the mold, which is much easier on you when it fails or doesn't come out!

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various Casting instrument, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer customers all kinds of overall solutions and turnkey project services, such as technical consultation, equipment selection, mold manufacturing design, process development as well as operation training and much more. We are confident that our products will create value to our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our firm has sold and manufactured over 2, 000 units in the last year. Casting instrument and reliability make our company have a good reputation with customers. Apart from sales in every city and province across the country Our products have also been shipped to Southeast Asia, Africa South America, Middle East and many other locations and have been a great success by customers. Based on the business ethos of cooperation and win-win, sincerity and honesty, BoQiao will continue to follow the path of professional growth and continuously improve products and services to meet the demands of customers. The need to assist customers in creating more value.

In 1979 we started our journey in the industry of cast iron with the purchase of casting materials This was the beginning of our experience and our presence on the market We've established lasting relationships with our clients over the years offering top-quality products and offering exceptional customer service In 1997 we expanded to include the manufacturing of industrial electric heaters This move was a strategic one that allowed us to provide more complete solutions to our clients addressing their growing demands for efficient and reliable heating equipment Our determination to provide quality and innovation distinguished us from the competition By 2002 we'd further diversified our offerings by introducing the production of casting machines This expansion allowed us to offer a wide array of casting options from materials to machinery and ensure that our customers could rely on us for all their casting needs Our vast experience and comprehensive understanding of the industry have established us as a trusted company for companies looking for top-quality casting equipment and support Since our beginning we've remained committed to continuous improvement and client satisfaction which drives us to change and evolve to the ever-changing Casting instrument

BoQiao's gravity-casting machine features an Casting instrument that makes it a great choice for many manufacturing environments. Its top-quality performance guarantees the most precise and accurate casting while its user-friendly system simplifies the process of production, allowing operators to produce the best results with minimal training. This multi-purpose machine is used in a variety of industries, such as motorcycle parts auto parts, auto parts electrical power fittings and engineering machinery. The machine's cost-effectiveness and durability makes it a great option for companies seeking solid casting solutions. It is praised by clients for its consistency in quality, simplicity of operating and maintenance, and the increased production.