×

×

Granular molding machines are specific computerized purchase creators that establish metal merchandise. They are extremely crucial in producing the things people bed for their day to day life. Numerous metal objects can be made with the use of these machines in very less time. This is the reason why they are so useful in respectively large production amounts, which can become especially significant when many items need to be processed/manufactured in just a short time

Most sand molding machines are made to create molds. Molds are the key that take metal and turn it into proper shapes. These molds are required for the proper functioning of all sand molding machines. The Boqiao Low Pressure die cast machines machine is loaded with sand, which gets pressed into a mold to shape the metal objects that are made. The sand must also be the correct size and type so as to create a quality end product; getObject applications can describe process specifics best.

Automating sand molds are extremely low crucial for generating metallic shapes that are utilized in a range of items. Then a part spiritual, part skill branch of individuals slot in their respective CAD drawings and information is used by the computers to form flawless shapes allowing better quality metal products with them. From sand mold is made of the precision, then automatic and can skew much more than conventional human powered such as regular hand operated castings. This improved accuracy is able to bode well with the sorts of parts they emerge

Automated Sand Molds These molds are created using computer designed and directed systems. The Boqiao Gravity die casting machines molds are also fine-tuned with the help of computers, to ensure compliance. This technology means that the metal forms are manufactured with fewer mistakes, a huge benefit. Not only are the metal shapes smoother, but their quality is also improved. The purchase price of an automatic sand casting cast is higher than that of a manually made core, but due to the quality and more control offered by automation in certain foundries it will pay off.

This new tech works by way of particular machines which can be used to provide moulds. Machines are very powerful, precise and a mold. Perfect output can be generated. Good molds help the metal shaping process much more by cutting down on mistakes. This Boqiao Aluminum casting parts means the final metal prints are also smoother, and just look better in general. Although this high-tech solution can be quite expensive, it does a fantastic job in ensuring proper product quality for manufacturing.

A custom sand molding machine of this type, works with its own specially made molds. The key is these are forms that will aid when it comes to shaping the metal fast and effectively. What this means is since no need curing time taken so you can produce a number of metal shapes easily and also within the shortest possible time. Although custom sand molding machines can be expensive, they are necessary components to a business's ability to improve production rates.

There are expensive machines which do the advanced level of work and they better be good at it, since all molds come from that. This improves the accuracy and strength of the machine thus improving its molding capability. It shapes the metal with fewer errors resulting in smooth and better shape. Although it is more expensive to be equipped with this advanced sand molding equipment, the better product quality that comes from its use results in a good return on investment for manufacturers.

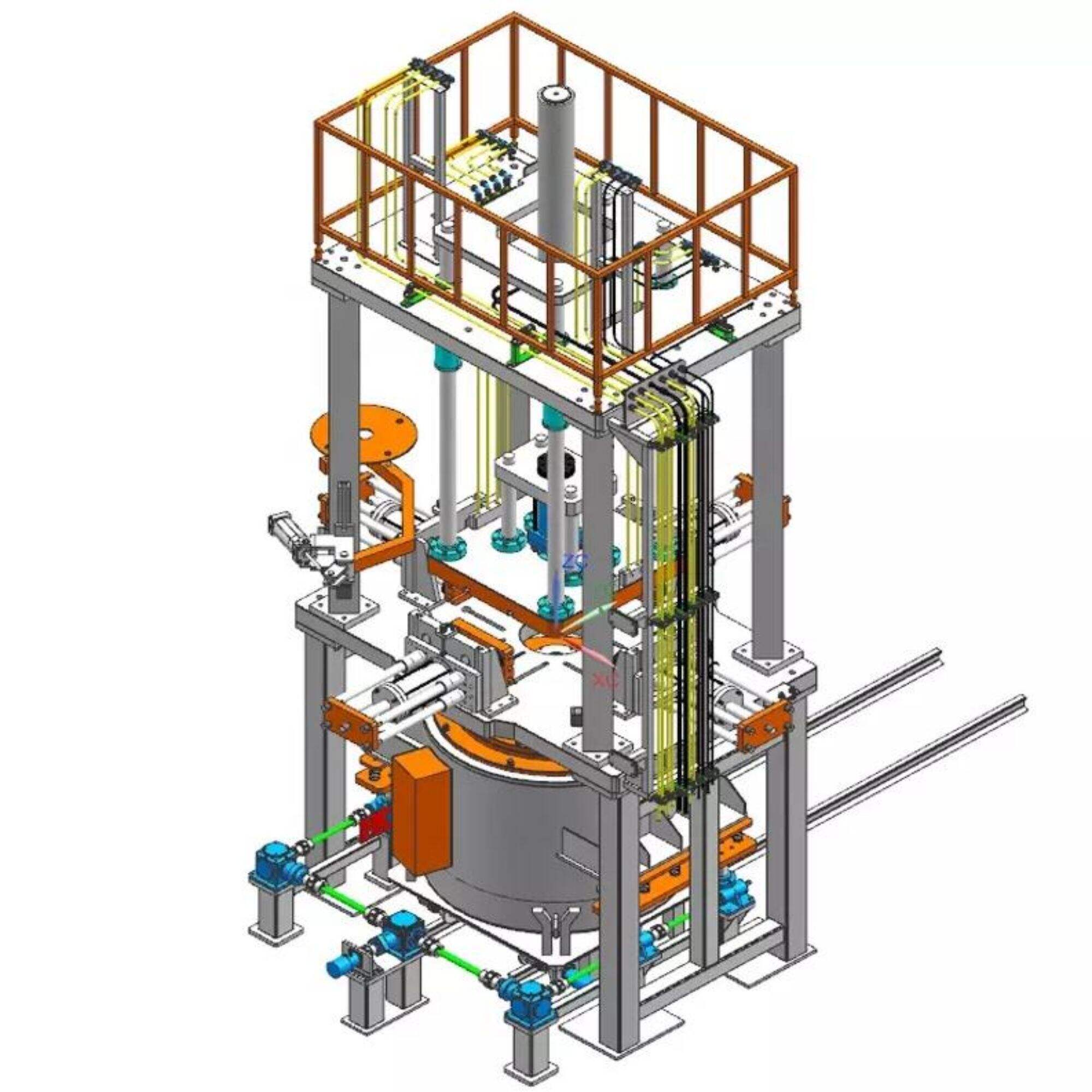

BoQiao's gravity-casting machine features an Sand molding machine that makes it a great choice for many manufacturing environments. Its top-quality performance guarantees the most precise and accurate casting while its user-friendly system simplifies the process of production, allowing operators to produce the best results with minimal training. This multi-purpose machine is used in a variety of industries, such as motorcycle parts auto parts, auto parts electrical power fittings and engineering machinery. The machine's cost-effectiveness and durability makes it a great option for companies seeking solid casting solutions. It is praised by clients for its consistency in quality, simplicity of operating and maintenance, and the increased production.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, Sand molding machine, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We can provide customers with diverse solutions and turnkey projects, including technical consultation, equipment selection, mold manufacturing design, process development operations training and so on. We are confident that our products will create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our journey into the field of casting began in 1979 with sales of casting materials that laid the groundwork for our experience as well as our market position Over the years we have built lasting relationships with our clients through offering high-quality products and excellent service In 1997 we expanded our services to include manufacturing of electric furnaces for industrial use This move was a strategic one that allowed us to offer more complete solutions for our clients and satisfy their increasing demand for high-quality reliable heating equipment At this point our commitment to quality and innovative thinking made us stand out from the competition In Sand molding machine we had further expanded into the manufacture of casting machines We were able to provide the full spectrum of solutions for casting including the materials as well as machinery This enabled us to become a one-stop store for our customers with casting needs Our experience and extensive knowledge of the industry has made us a reliable partner for businesses seeking top-notch casting equipment and services We've always been devoted to customer satisfaction and continuous advancement This has driven us to evolve and adapt in a marketplace that is ever-changing

Since 1999, our company has Sand molding machine and sold over 2000 units. Our company has a stellar reputation among its customers due to our reliability and quality as well as excellent customer service. In addition to selling in all cities and provinces across the nation Our products have also been offered to Southeast Asia, Africa South America, Middle East and many other locations, and have been a great success by customers. Based on the business model of win-win and cooperation, honesty and sincerity, BoQiao will continue to pursue the path of professional development and constantly improve products and services to meet the development of customers. It is essential to help customers create more value.