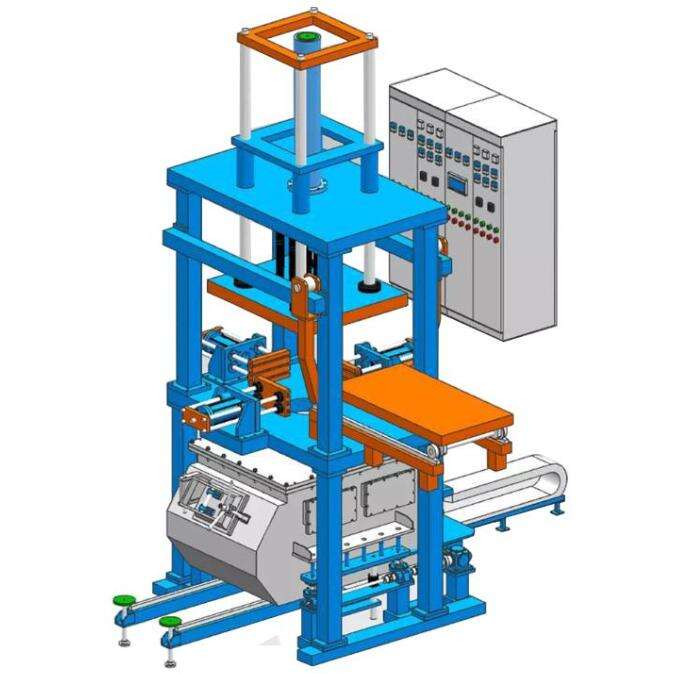

Casting machines are a type of equipment for the manufacture of metal and plastic products in general by casting. They are available in a variety of sizes and shapes, they can be used whenever required as well. These robots are generally utilized in sectors like auto, medical, aerospace and so on. Top 4 Casting Machine manufacturers Top used and the best castings machine manufactures through out world discussing their advantages with innovation and safety features Delivery, & Application How to take free service from them

Benefits of Casting Machines:

There are plenty of advantages to using casting machines First and foremost, they are extremely efficient - able to churn out a large quantity of products quickly and cheaply. Second, they help ensure product measurement accuracy to cut down on production error and waste. They also offer the flexibility for tailoring the item according to most requirements. And finally, casting machines help in automating the process of production hence saving extensive human labour.

New Trend for Casting Machines:

All the casting machines are produced by investing new technology in designing and developing of these machine from manufactures. This innovation enhances the quality of machines as well in final products. Take, for example, that they utilize 3D printing technology to produce high-detail product designs. In addition, they use artificial intelligence to optimize the efficiency and precision of these machines.

The Safety of Casting Machines

Casting machines are dangerous to use given the high temperatures of molten metals and plastics, which can lead to serious burns. For this purpose, manufacturers integrate safeguards to minimize the risks chances of accidents in their machines. Safety features include pressure build up sensors, an automatic shutdown feature if the power is cut and emergency stop button to halt operations swiftly in case of emergencies.

How to Use a Casting Machine:

Operating a casting machine: Insert the mold into the machine and load your cast material to begin operating. Then, start the casting process by turning on the heat source of this machine. The manufacturer will specify the heat and pressure to be used in casting, which must also be adhered to.MetadataInjection TPH-TOR-0096 Lastly, remove the finished product from your mould.

Top 4 Casting Machine Suppliers:

b. Buhler- Originating from Switzerland, casting machines produced by State of the art techniques for exact product measurement and very God to mass production(split into two) It is known for its excellent customer service and high quality machines.

Italpresse Gauss An Italian company, Italpresse Gauss is non-stop changing the way of producing casting machines by high-end technology to create thinner walls at a greater yield. Their equipment is state of the art and very simple to use.

c. Toshiba Machine: Having been around since over 75 years, this Japanese company is known for its plethora of casting machines with high end specifications ideal to perform mass production systematically. Their systems are of technological standards and user-friendly as well.

d. Frech: A German company, specializes in high-end casting machines that are associated with being state-of-the-art equipment, integrated processes like digitalization AI and IOT as well Their machines are designed to automate, safe, accurate and high productivity.

Concluding note - So, this was all about the best four casting machine manufacturers globally displaying their advantages, innovations they brought in safety measures,wheoralusage and apocolifeocations. It is especially important for the casting industries to choose efficient and effective casting machines in their processes. While casting machines have a lot of benefits, safety comes first - and that means following manufacturers recommendations for best practices to ensure safe operation.