Sweden's Engineering Pedigree and Casting Needs

Sweden's manufacturing backbone is legendary. It’s a place where heavy industry and high-tech innovation collide, creating a unique demand for robust and precise machinery. Gravity casting, a process relying on simple physics to fill molds with molten metal, is fundamental here. It’s not about brute force; it’s about control and consistency. For companies producing everything from complex automotive components to specialized marine hardware, the choice of gravity casting machine is critical. The right equipment ensures micro-structural integrity in the final casting, a non-negotiable for parts facing extreme stress or temperature. Swedish manufacturers, known for their exacting standards, don't just buy a machine; they invest in a production partner. This creates a market where only the most reliable and technologically adept equipment suppliers can truly compete. The relationship between machine builder and foundry is often a long-term dance, one built on mutual understanding of metallurgy and production goals.

Aluminum casting parts play a crucial role in meeting the demands of precision engineering and manufacturing in Sweden.

Navigating the Swedish Manufacturing Landscape

Finding a gravity casting manufacturer in Sweden requires looking beyond a simple spec sheet. You have to consider the local ecosystem. There's a certain pragmatism in Swedish engineering, a focus on solutions that work day in, day out, often in harsh conditions. The long, dark winters seem to breed a preference for equipment that is not only efficient but also incredibly durable and easy to maintain. From my own visits to workshops outside Gothenburg, I've seen how machinery is integrated into workflows. It’s not just about the casting process itself; it’s about how the machine interfaces with material handling, mold preparation, and post-casting cooling lines. A manufacturer that understands this holistic view, one that can offer a machine designed for seamless integration rather than just standalone operation, holds a distinct advantage. The best suppliers think about the entire production cell.

When looking for a gravity casting machine in Sweden, it is important to consider factors beyond just technical specifications. Understanding the local engineering ecosystem is key.

A View

from the Workshop Floor Having spent years around casting operations, the difference between a good machine and a great one often comes down to the little things. How easily can a mold be changed over? What is the accessibility for daily maintenance? Is the control system intuitive for the operator, or does it require a PhD to decipher? These are the practical concerns that determine uptime and productivity. A machine might have the most advanced servo-drive system, but if its ladle mechanism is finicky, it becomes a bottleneck. I recall a situation where a simple design tweak to a pouring basin, suggested by an experienced floor technician, increased yield by three percent. That’s real impact. It’s this granular, hands-on experience that separates theoretical engineering from practical manufacturing excellence. Suppliers who value this on-the-ground feedback and incorporate it into their designs build immense loyalty.

Paying attention to details like ease of maintenance and operator-friendly controls can significantly impact the efficiency and productivity of a gravity casting machine.

The Global Partner

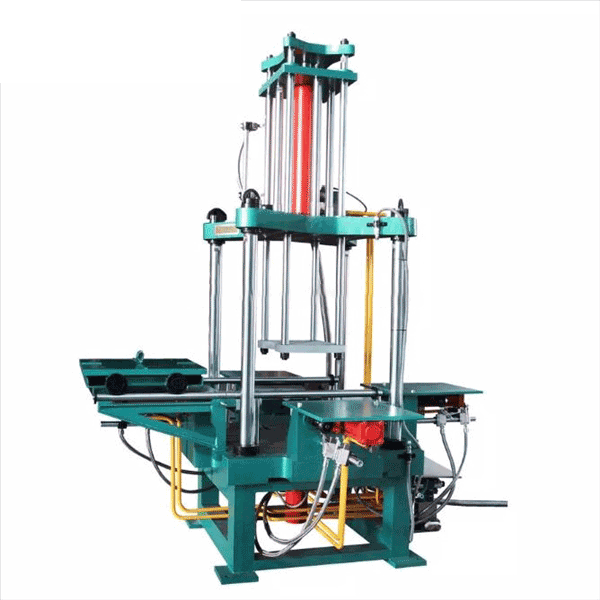

While the focus is on Sweden, it’s impossible to ignore the global nature of industrial supply chains. A company like ours, Nanjing Boqiao, operates in this space. With over twenty years building casting machinery, we’ve seen trends come and go, but the core principles remain. Reliability. Simplicity. Performance. Our gravity casting machines are used worldwide, and the feedback from different markets is invaluable. The stringent requirements of a Swedish aerospace foundry, for instance, push us to refine our tolerances and control logic in ways that benefit all our customers. It’s a two-way street. We learn from the high standards of Swedish industry, and in turn, we offer a product honed by diverse, global application. This isn’t about just selling a machine; it’s about bringing a wealth of cross-border experience to a local challenge, ensuring that Swedish manufacturers have access to world-class technology that understands their specific needs. The goal is partnership, not just a transaction.

Companies like Nanjing Boqiao offer BQ quenching furnaces that meet the rigorous demands of Swedish industrial standards.

Ultimately, the machine is just one piece. The real value comes from the support wrapped around it. Training for operators, availability of spare parts, technical support that can troubleshoot a problem quickly. A manufacturer needs a supplier that will be there for the long haul. The initial purchase is just the beginning of the relationship. The climate can be tough on equipment. The metallurgical requirements are always advancing. A static product is a dead product. The best manufacturers on any list will be those who demonstrate a commitment to continuous improvement, not just of their machinery, but of their entire service offering. They adapt to new alloys, new safety standards, and new automation technologies. They help their clients future-proof their operations. That’s the true mark of a top-tier gravity casting machine manufacturer, in Sweden or anywhere else. It’s a commitment that extends far beyond the factory floor.

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY