Continuous Cast Machines Are Vital Waste Minimizers in the Aluminum Business Permanent mold, semi-conductor and direct chill casting machines are essential machines to have in place in any aluminum foundry. These machines provide several benefits and are also useful to enhance the overall efficiency of your production process. Continuous casting technology is also a large contributor to wasting less and keeping manufacturing sustainable

The Benefits of Using Continuous Casting Machines in Aluminum Production

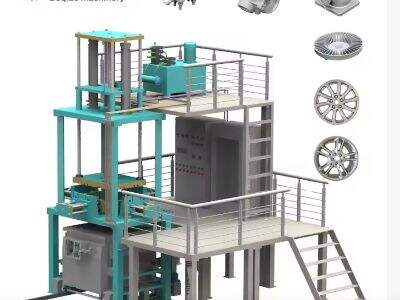

A process and apparatus is provided for casting aluminum products. A continuous casting machine provides a number of improvements with respect to efficient production of aluminum products. One thing is it produces aluminum continuously and ease without any shown with this way we have less waste. Continuous casting machines, by eliminating the stops and starts of the production process, allow for a more continuous and efficient manufacturing facility

What's more, continuous casting process can realize accurate control of the size and profile of the aluminum products you produced. This ability to manage ensures a reduction in the amount of scrap produced and individual jobs can be optimised for maximum efficiency. Moreover, the uniformity and consistency realized in continuous casting machines produce superior aluminum products that comply with tough industry standards

Minimising Waste in Aluminium Production with Continuous Casting Technology

Continuous Casting machines are an important part of limiting scrap in the production of aluminum by reducing the amount of discard and maximizing how you use material. The casting process involves no breaks and joins, which translates into less waste material with obvious financial savings at the same time as increased sustainability

Continuous casting also produces aluminum products that have fewer flaws and irregularities. This leads to greater yield of operable products and less waste produced during manufacture. The continuous casting machine can make aluminum manufacturers more efficient and more sustainable while reducing their environmental footprint

Continuous casting machines are important equipment in aluminum industry for waste reduction and overall production efficiency improvement. The performance of the aluminum manufacturers that can capitalize on continuous casting technology to streamline their operations, reduce scrap and improve product quality. This environmentally friendly way of making textiles not only serves to be better for nature, it also contributes to the growth in the industry

Optimizing Your Profit Margins with Continuous Casting Machines

For manufacturers, CCMs are creating a significant impact in the aluminum production process as they allow companies to increase profit margins. These machines also give the ability to make aluminum products in uninterrupted line of production thereby minimizing effort and time involved in making each item. More simply, by cutting production, they can boost higher profits simultaneously as lowering production costs. This efficiency allows companies such as Boqiao, who apply continuous casting machines in their manufacturing plants, to achieve a higher profit margin

Less Environmental Burden Through the Continuous Casting Process

Apart from maximizing productivity, continuous casting machines also contribute to making the aluminum production process more eco-friendly. Process Overview Conventional manufacturing processes often produce waste where off cut material is disposed of through the production process. Continuous casting machines limit waste and carbon emissions by casting rolling aluminum in a single, continuous process that eliminates the need for edge-trimming scrap. Not only does this allow companies like Boqiao to operate more sustainably, it also results in a cleaner, greener world for all of us

Where You Can Get High-Quality Continuous Casting Machines for Aluminumcesting for Steel Production

Top-Quality Continuous Casting Machines for Aluminum Production When it comes to searching for the highest standard of continuous casting machines for aluminum production, companies such as Boqiao will go to a renowned manufacturer who is specialized in this technology. These machines are long term investments so finding a reliable source that can supply top quality, industry standard products is important. By researching reputable manufacturers and reading customer reviews, as well as comparing pricing and features, companies can find quality continuous casting machines. By investing in the best equipment available, businesses can significantly minimize downtime, reduce labor costs and boost profit margins during their aluminum manufacturing processes

Table of Contents

- The Benefits of Using Continuous Casting Machines in Aluminum Production

- Minimising Waste in Aluminium Production with Continuous Casting Technology

- Optimizing Your Profit Margins with Continuous Casting Machines

- Less Environmental Burden Through the Continuous Casting Process

- Where You Can Get High-Quality Continuous Casting Machines for Aluminumcesting for Steel Production

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY