Seal quench furnaces are important in eliminating oxidation while hardening aluminum. These furnaces are engineered to produce an enclosure that reduces the exposure of aluminum to oxygen, a situation that can result in oxidation and an end product of less than top quality. Boqiao realizes that It is the sealed quench furnace in China provide the best aluminum hardening. So, now let’s take a look at the benefits of sealed quench furnaces for your aluminum hardening and how it will keep oxidation from ruining the product

Benefits of Sealed Quench Furnaces for Oxidation Protection

There are several important advantages of sealed quench furnaces in terms of avoiding oxidation at the surface during aluminum hardening. One of the main reasons is that a sealed environment where as little aluminum as possible is exposed to oxygen can be created. This controlled environment helps to prevent oxidation, which can cause surface defects, diminished hardness and lessened product life. Sealed Quench Furnaces Make It HappenManufacturers such as Boqiao can finish aluminum hardening like this by using sealed quench furnaces. Sealed quench furnaces further ensure the risk of oxidation is minimized while ensuring even results by keeping a constant temperature during the hardening process. In general, the employment of sealed quench apparatuses is indispensable for avoiding oxidation and obtaining good results in aluminum hardening

How Aluminium Hardening Is Enhanced by Sealed Quench Furnaces

SEALED QUENCH part of the Furnace Hardening Process for Aluminum For aluminum hardening, new development Sealed Quench heat treating furnaces bring major benefits. Since they create a controlled environment, in which the exposure to oxygen is relatively small, these furnaces contribute to preserving of aluminum quality and preventing oxidation defects. This results in a better end product with improved mechanical properties and superior wear resistance. The use of sealed quench furnaces also enhance the control of temperature as to annealing and hardening levels required to heat/cool aluminum at optimum attribute levels. Boqiao employs sealed quench furnaces that enhance the hardening of aluminum to produce world-class products. In other words sealed quench furnaces are necessary for attaining repeatable, uniform results in aluminum hardening that are indispensable to manufacturers who want to provide the best possible level of quality and value to their customers

Best Quality Sealed Quench Furnaces for Bulk Purchasers

The right tools for aluminum hardening Whether it's milling, drilling or turning applications – other cooling equipment available on the market are too widely spread when it comes to aluminum hardening. Boqiao presents high-quality sealed quench furnaces suitable for wholesalers who need to enhance the hardening of aluminum. These ovens are built not to oxidize during the hardening process so your aluminum parts come out looking and performing great

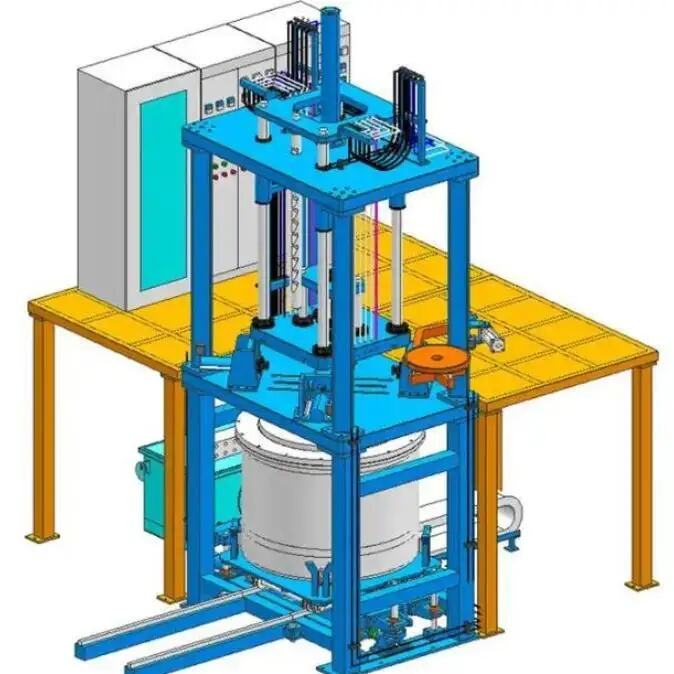

Boqiao's industrial sealed quench heat treatment furnaces use high-quality material and state of art technology to guarantee the stability and reliability. They are simple to use and maintain, so they are a wonderful addition for large scale wholesale customers looking to simplify the way in which they harden aluminum. With Boqiao’s sealed quench furnaces, you can rely on your aluminum parts being hardened the same every time

Advantages of Using Sealed Quench Furnaces

Aluminum hardening with sealed quench furnaces has many advantages. One major benefit is that they block oxidation throughout hardening. Oxidation can compromise the integrity of aluminum parts, and shorten their lives. This is why you need a sealed quench furnace to preserve your parts

Not only do sealed quench furnaces protect your parts from oxidation during heat treating, but they facilitate very accurate temperature control in order to ensure the uniform and predictable hardening of your aluminum. The result is better performing, longer lasting parts. Sealed quench furnaces The sealed quenching chamber furnace are also energy efficient and save wholesale users on operating costs as well while still producing wonderful results

Why You Can't Do Without Sealed Quench Furnaces for Aluminum Hardening

Sealed quench heat treating is very critical in aluminum hardening as it creates a custom atmosphere of carbon dioxide or nitrogen that prevents oxidization and maintains accurate temperature readings. Without a closed quench furnace system in place, aluminum component parts are vulnerable to the production of weak or defective points which can affect their performance

Through the application of a Boqiao sealed quench furnace, wholesale clients will know with certainty that their aluminum components are being hardened to nothing but the best qualities attainable. These furnaces are engineered to be repeatable, delivering rock solid performance batch after batch and making them a valuable addition for any wholesaler who is in the market for enhancing aluminum hardening techniques. So, with Boqiao's sealed quench furnaces for your aluminum parts you can rest assured that they will meet or exceed the industry standard for quality and functionality

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY