×

×

The cylinder heads are an essential element of the engine. They are necessary in controlling the flow of air and fuel that occurs inside the engine, allowing it to run correctly. Boqiao Aluminum casting parts are necessary for an engine to work properly. A process that can be used to manufacture these critical parts is the cylinder head molding casting. Hot metal is poured into the mold to form cylinder head in this process. In this text we will look at the numerous benefits, costs and challenges associated with the manufacture of cylinder heads by this method.

Molding casting has many advantages to produce cylinder heads. Number one, the Boqiao cylinder heads made this way can be extremely accurate In turn, this is good because one of the biggest factors in how well an engine operates is its specific design for interchangeable parts. Fitment means better performance and a longer life of the engine. One of the other major advantages is that molding casting allows for a huge production volume of cylinder heads in short order. This efficiency is useful because it saves money on production costs. The more parts a manufacturer can make in less time, the cheaper it gets for consumers.

Molding casting techniques for making the cylinder heads can be seen as an intelligent path to having a production while not spending too much. These techniques reduce the material consumption and result in less waste, hence makes production costs lesser. This will allow manufacturers to lower their costs on materials, and also have a net positive impact on the environment by reducing waste. Furthermore, the BQ quenching furnace casting process is less time-consuming and means that cylinder heads are available significantly sooner. Such quicker turnaround time is beneficial for the consumers as this ultimately reduces prices of products they desire. In short, molding casting is a good solution for the cost-effective production of cylinder heads.

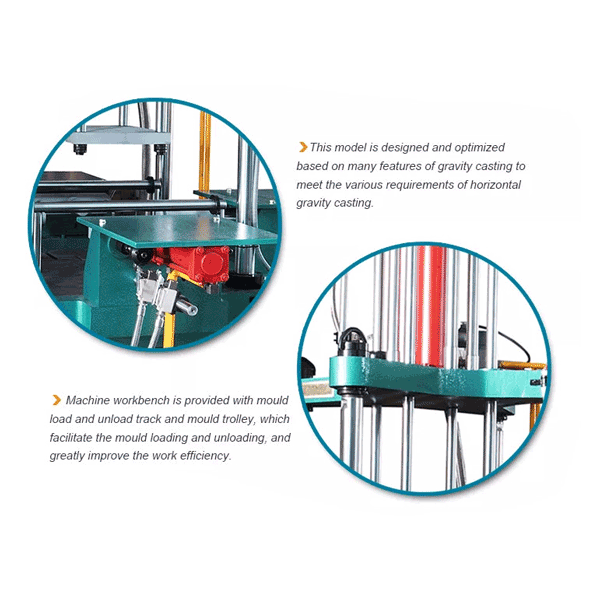

Cylinder heads can be based on many third types of molding casting technique. Sand casting is a common type. The casting process provides a die formed cylinder head from sand, meaning they come in any size and any shape that you can imagine. Many, and it is very versatile. Boqiao Gravity die casting machines is another types of molding where mold are made from steel. This is the more precise method and gives manufacturers flexibility in creating thinner, lighter covers. Lost foam casting, shown below, is another technique that uses an expendable pattern (often made of some type of engineered polystyrene) to create the mold for the cylinder head. Although all these methods have their particular advantages, depending on the needs of a given production process.

Despite benefits of molding casting, there are a number challenges that one may encounter by the manufacturer. There is a general issue and that has to do with the mold quality in cast molding. If this mold is not made correctly, the end product may have defects that could hinder its performance or function. In true metal casting, the choice of material for molding will be a challenge too. If the metal chosen is not correct, chances will be that your cylinder heads are weak and rusting problems may arise in future. Lastly, the Low Pressure die cast machines challenge to get qualified and expert local workers in cylinder head molding casting also afflicts.

BoQiao's Gravity Casting Machine has a compact design, which makes it a good choice for many manufacturing settings. Its superior performance ensures efficient and precise casting, and its user-friendly interface makes the production process, allowing operators to achieve optimal results with little training. This multifaceted machine is widely used in a variety of industries, including motorcycle components auto parts, auto parts, Cylinder head molding casting, and engineering machinery. The durability and affordability make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by its customers due to its constant quality, ease of operating and maintenance, and the increased efficiency.

Cylinder head molding casting is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We can provide customers with all kinds of overall solutions as well as turnkey projects that include technical assistance, equipment selection mold manufacturing, process development, operation training and more. Our products can create value for our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

In 1979 we started our journey in the field of Cylinder head molding casting through the purchase of casting materials This was the start of our knowledge and presence in the marketplace Through the years we've built long-lasting relationships with our clients by providing high-quality products and exceptional service In 1997 we expanded our business to include manufacturing of industrial electric furnaces This strategic move allowed us to provide more comprehensive solutions for our clients and satisfy their increasing demand for dependable efficient heating equipment Our commitment to innovation and high-quality during this time period stood us out in the competitive landscape By 2002 we diversified our product offering by moving into the manufacturing of casting equipment sector This expanded our capabilities to provide a complete selection of casting solutions from materials to machinery to ensure that our clients could trust us with all their casting needs Our experience and extensive knowledge of the field have earned us the reputation of a reliable supplier for companies seeking top-quality casting equipment and services We've always been committed to customer satisfaction and continuous improvement This has enabled us to evolve and adapt in a market that is constantly changing

Our Cylinder head molding casting has sold and manufactured over 2, 000 units from 1999. Reliable quality and excellent service make our company enjoy a great reputation among customers. In addition to sales in every city and province across the country Our products have also been offered to Southeast Asia, Africa South America, Middle East and other regions, and have been a great success by customers. Based on the premise of win-win and cooperation, sincerity and honesty, BoQiao will continue to pursue the path of professional development and continuously improve products and services to better meet the demands of customers. The need to assist customers in creating more value.