×

×

Did you ever wonder how metal things are made? Well that’s an interesting thing to look out for! Shell molding casting is the way to create metal objects. The first thing to do is prepare a mold. A mold is a hollow form that the metal takes to give it the shape you want. For shell molding casting the mold is made from a substance that is a mixture of thermosetting resin an sand. A mixture is formed to pour the desired result we do this until it has been heated well. Afterward, when it is gotten hardened, Boqiao Gravity die casting machines is done.

The next thing that is done is the transformed by taking the poured melted metal. By pouring the melted metal into the hallow transformed through a particular sprue opening it is known as the gate. During this process is necessary as full attention must be considered so it does not spill over or fill up in an uneven way. This will be the destruction of the good of the final product. When this dulls, apart, the mold is removed and inside is the desired transformed metal object.

That said, shell molding casting usage does have some of its challenges and disadvantages. For one, the equipment required to do so is expensive and difficult to deploy. Boqiao Low Pressure die cast machines means that companies should be prepared to go all in on this and invest some money out of pocket just to get started. The shell molding casting process is also slow when compared to other ways of producing metal objects. Manufacturers who need to work quick, this can be a disadvantage. Finally, molds can be more difficult to make for irregular objects. Additionally, if the shape is too complex it can become difficult to produce a precise mold which includes all of these details.

Shell molding casting is not immune from issues, but it remains a tried-and-true technique for producing metal objects. The process needs new ways of being done faster in the industry. An area with a lot of promise for increased usage is the production of aircraft and spaceships parts via shell molding casting. A major advantage, as these are typically mean very complicated metal parts which can be difficult to produce through other means.

The automotive market has seen a spike of interest in the advances that are being made into shell molding casting too. Given the need for a variety of metal parts to build vehicles, Boqiao BQ melting furnace comes as no surprise that many applications in automotive manufacturing require those same tight tolerances and precision which are offered by shell molding casting. With a growing and changing automotive industry, shell molding casting is likely here to stay for the production of metal objects in high-quality designs.

The shell molding caste is one of many manufacturing processes, which means it has its own problems. One common problem is the heating and curing of molds. If the mold is not heated sufficiently, it may be unable to withstand the force of liquid metal and weak entry area. This could bring on a host of issues. While on the other hand if the mold is not enough hardened, BQ quenching furnace may fall off or crack when you started pouring metal.

Now that you are familiar with shell molding casting, the question on your mind is probably, does this make it the best way to produce metal objects? The reality is that there isn't a universal way to produce metal Aluminum casting parts and no best in each category. Shell Molding Casting For those wanting extremely accurate and fine metal objects casting using shell, might be the best option. That more redundancy is unsuitable for the vast numbers of straightforward metal parts that manufacturers might need, but other methods may be cheaper.

BoQiao's Gravity Casting Machine has a compact design, which makes it a good choice for many manufacturing settings. Its superior performance ensures efficient and precise casting, and its user-friendly interface makes the production process, allowing operators to achieve optimal results with little training. This multifaceted machine is widely used in a variety of industries, including motorcycle components auto parts, auto parts, Shell molding casting, and engineering machinery. The durability and affordability make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by its customers due to its constant quality, ease of operating and maintenance, and the increased efficiency.

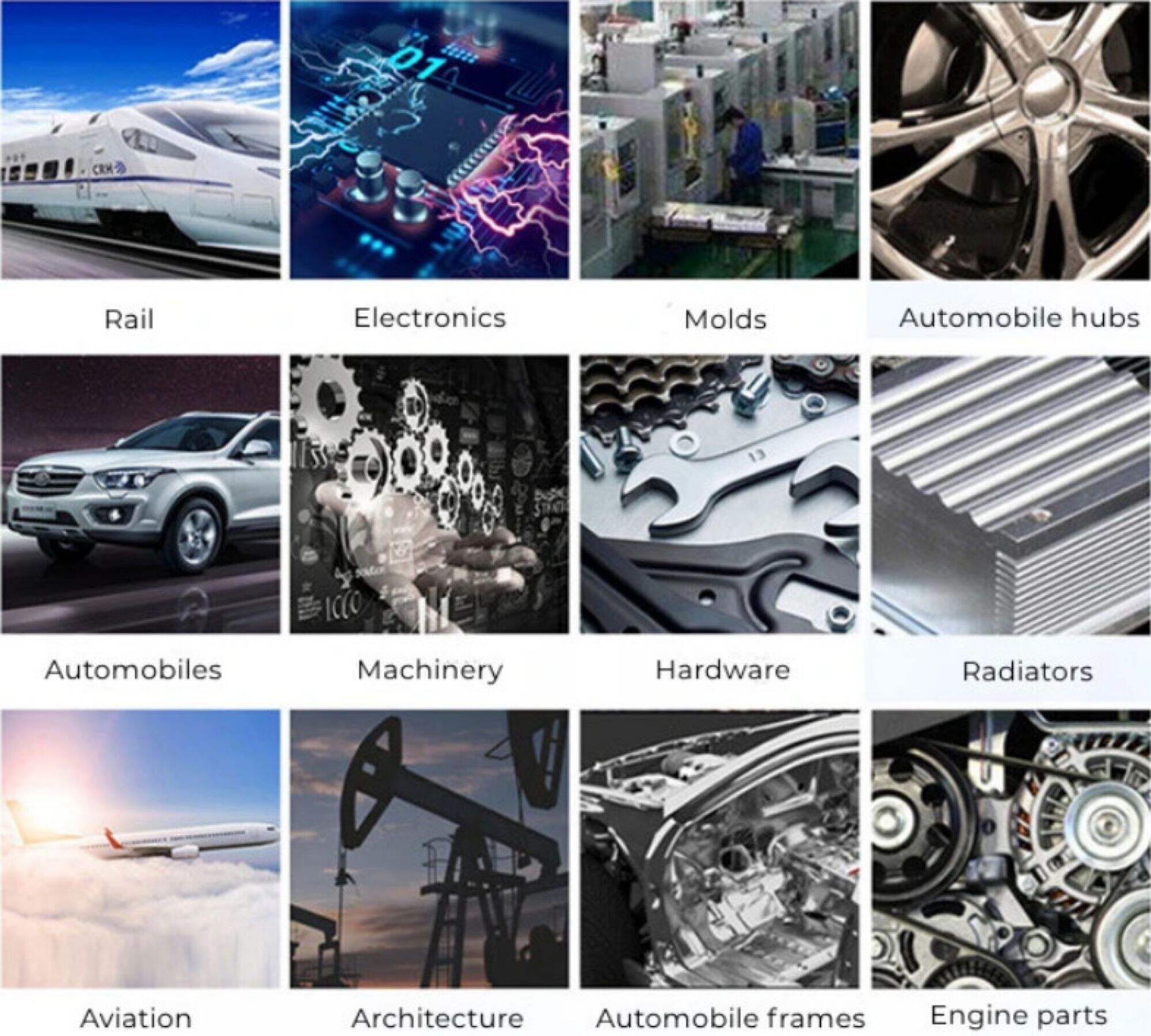

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, Shell molding casting and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include the technical support, selection of equipment and manufacturing processes, design, training and operations. Our products can create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Shell molding casting journey into the field of casting began in 1979 with selling of casting material that laid the groundwork to our industry expertise as well as our market position. We've established lasting relationships with clients over the years by offering high-quality products, and providing exceptional service. In 1997, we grew to include the manufacturing of industrial electric heaters. This was a smart move that enabled us to offer more comprehensive solutions for our clients and satisfy their increasing demand for efficient, reliable heating equipment. Our determination to provide quality and innovation set us apart from the crowd. In 2002, we'd diversified our offerings by introducing the production of casting equipment. This expansion allowed us to provide a comprehensive array of casting options, from equipment to materials, ensuring that our clients can rely on us for everything they require in casting. We have earned the reputation of a reliable business partner because of our extensive experience and knowledge in the casting industry. Throughout our history, we have remained dedicated to constant improvement and customer satisfaction, which drives us to grow and change to a changing marketplace.

Our company has sold and made over Shell molding casting units since 1999. Excellent service and reliable quality make our company have a good reputation with its customers. The company has sold its products to Southeast Asia and Africa South America as well as the Middle East. Customers have also been satisfied with the service and quality. Customers should be encouraged to create more value.