×

×

Metal is a highly valuable substance, because it is used in various areas of our daily existence like machines, motor vehicles and aircrafts. This means that all the machinery and cars that make life simpler are also available. To perform this particular task, squeeze casting is done using metal shaping methods known as back button die casting. Squeeze casting produces strong and very precise metal shapes. This method is efficient and helps to reduce wastage in metal production hence leading to cost savings.

Casting: Metal parts can be manufactured using a traditional method where the metal is poured and solidifies in a mold to form the desired object. In Boqiao squeeze casting, we heat up metals till they are molten and then pour it into molds which are basically containers that shape the melted metal. Ironically, this age-old process of casting has been known for inaccurate products due to weak structure. This brings about the need for squeeze casting. It is without doubt an exceptional type of cast/branding fire. Squeeze Casting- A pressure is applied to squeeze molten metal into the mould during the casting process. The enhanced pressure aids in better filling of mold which yield stronger and dimensionally accurate components than conventional processes of casting.

In squeeze casting, the pressure is of great importance to press the molten metal into the bottom and flow channel of a mold, so that it can totally fill in its cavity. In this case, there will be no air pockets or cavity between the metal. Air bubbles make the metal less dense as a result weaker and certainly not accurate enough as compared to when they are absent. Still in squeeze casting, we can have thin walls of about 1mm thickness including fine details such as lettering on an emblem. The high pressure pushes the metal into every nook and cranny of our complex molds, meaning that we can make small intricate parts which are manufactured according to our specifications with impeccable tolerances.

This is because it produces stronger metal parts than all the conventional techniques. It is made by using small pieces of metals and the pressure in squeeze casting aligns these grains of metals. The result is that this type of structure makes a harder type of metal that wears better over time. Other methods may not distribute grain evenly, which can lead to parts with less strength that are more brittle. Besides, Boqiao squeeze cast drastically decreases the number voids or holes in the metal. With fewer holes it becomes so much stronger and has wider applications.

When manufacturing complex shapes, squeeze casting can be preferred. This allows for creating intricate designs having undercuts, thin walls or tiny corners simply. There are only certain configurations possible when using shaping methods like forging and machining. However, Boqiao casting squeeze deals effectively with those challenging geometries hence making it an ideal choice among manufacturers who require one-piece precision metallic parts or detailed accuracy.

The benefit of squeeze casting also goes beyond saving a lot of money on this production method through waste management. Other casting methods typically result in excess material that they either recycle or dispose of. Compared to mold casting, squeeze casting is faster and has more accurate filling of a mold making it have minimal waste. This results to metal that is produced per unit volume, thus increasing the efficiency and reducing material wastage. Additionally, squeeze casting can create net shape parts with higher tolerances meaning better surface finish without any added work for which materials are wasted leading to less production costs.

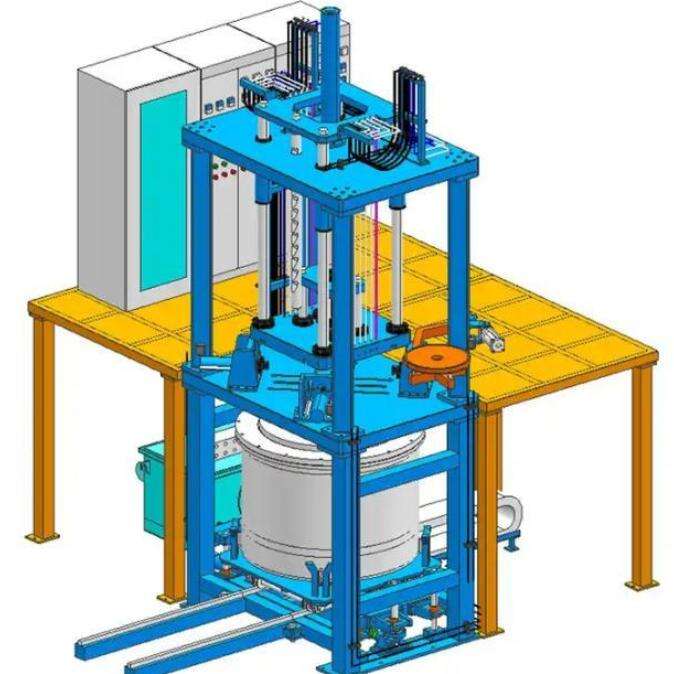

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, Squeeze casting manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We are able to provide customers with all kinds of overall solutions and turnkey projects including technical consultation, equipment selection, mold manufacturing and process development, operation training and so on. Let our products add the value our customers need. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

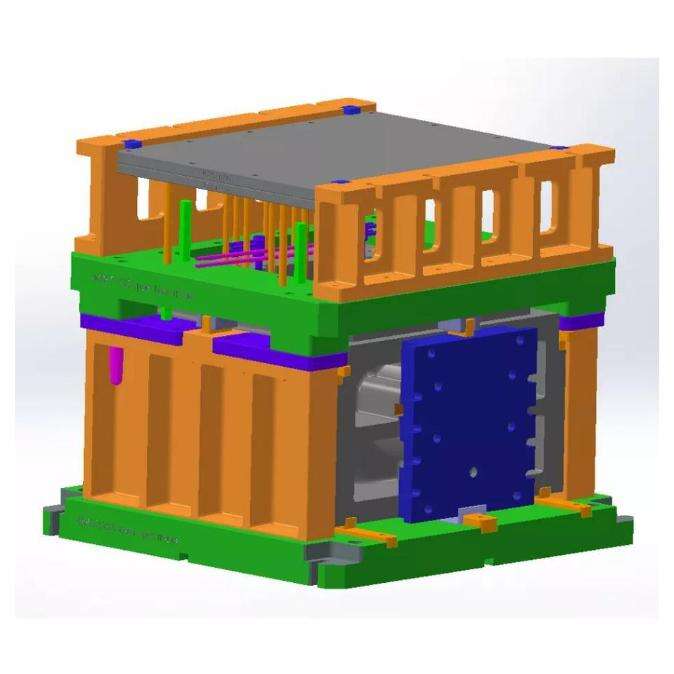

The BoQiao gravity casting machine is Squeeze casting with a small structure and is a perfect choice for various production environments. Its high-performance makes for accurate and efficient casting and the user-friendly design makes the production process, allowing operators to attain the highest quality outcomes with only minimal training. This multi-purpose machine is used in a variety of sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it an investment worth making for companies looking for reliable casting solutions. It is praised by customers for its dependable quality, easy operation and maintenance and increased production.

In 1979 we started our journey in the field of Squeeze casting through the purchase of casting materials This was the start of our knowledge and presence in the marketplace Through the years we've built long-lasting relationships with our clients by providing high-quality products and exceptional service In 1997 we expanded our business to include manufacturing of industrial electric furnaces This strategic move allowed us to provide more comprehensive solutions for our clients and satisfy their increasing demand for dependable efficient heating equipment Our commitment to innovation and high-quality during this time period stood us out in the competitive landscape By 2002 we diversified our product offering by moving into the manufacturing of casting equipment sector This expanded our capabilities to provide a complete selection of casting solutions from materials to machinery to ensure that our clients could trust us with all their casting needs Our experience and extensive knowledge of the field have earned us the reputation of a reliable supplier for companies seeking top-quality casting equipment and services We've always been committed to customer satisfaction and continuous improvement This has enabled us to evolve and adapt in a market that is constantly changing

Squeeze casting company has sold and manufactured more than 2, 000 units from 1999. Reliable quality and excellent service make our company enjoy a positive reputation with customers. In addition to selling in every city and province across the country our products have been shipped to Southeast Asia, Africa South America, Middle East and various other countries and are well-received by customers. Based on the business philosophy of win-win and cooperation, honesty and sincerity, BoQiao will continue to follow the path of professional growth and continually improve its products and services to better meet the needs of its customers. Customers need to be assisted in helping make more money.