×

×

There is a way of addressing this by using a molding machine, which is used in the production of many items through what is called injection molding. Injection molding can be described as an interesting method whereby plastic stuff gets melted, goes through a mold before being cooled to harden in that shape. Consequently, mold machine can make nearly anything ever imagined like toy cars, smartphone covers and even parts for more complex machines.

How Does Mold Machine Work? To begin with, plastic pellets are heated up until they melt. Then, the molten plastic is forced into the mold using a device known as an injector. This injector plays a key role because it ensures that the mold fills up completely with molten plastic. After that, it cools down and hardens inside the mold into its designated form. This allows multiple similar products to be produced within a relatively short period.

Mold machines have many advantages and one of the greatest is time savings and cost savings for businesses. Thus, a Boqiao mold machines can produce multiple copies of the same item in bulk within a very short time rather than having to make everything by hand over countless hours. In other words, it makes firms to be able to manufacture things faster thereby reducing costs and generally enabling companies to become more successful.

However, using a mold machine also has its disadvantages: To start with, these machines are relatively expensive to buy and maintain; First of all, it means that firms must pay a sizable amount of money for this thing and then have a financial responsibility for repair and maintenance of their own stuff. Furthermore, mold machines only allow certain shapes and sizes; this implies that should you happen to be developing something outside this category except those brands then it may need an alternative production method for you.

Looking after the mold machine will give good results in terms of saving the buying company money over a long run. In simple words, it implies that if it is maintained well, the probability of just coming to a halt are minimized. On top of this, one of the worst situations that could occur is an accident or problem happening which may lead to workers being injured and / or products being damaged even before expiry dates.

Finally, you should also consider the kind of products that can be produced through the use of mold machine. Such equipment may not work efficiently as expected; they can be too slow during use or limited to certain types of plastics/materials only. This means that if at all you are able to produce many different items from it therefore, then the machine must have enough capacity on how many different parts might be managed by these Boqiao molding machines.

Mold machines have been gradually developed like any other technology. The growing smart machine software innovation is another competitive market to watch out for in the future. Therefore, sensors with control mechanisms and IoT technology have been integrated into this Boqiao molder to trace the manufacturing process on a real-time basis. In so doing, companies can keep an eye on machine performance as well as effect changes if need be.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, Mold machine, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We can provide customers with diverse solutions and turnkey projects, including technical consultation, equipment selection, mold manufacturing design, process development operations training and so on. We are confident that our products will create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Mold machine customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

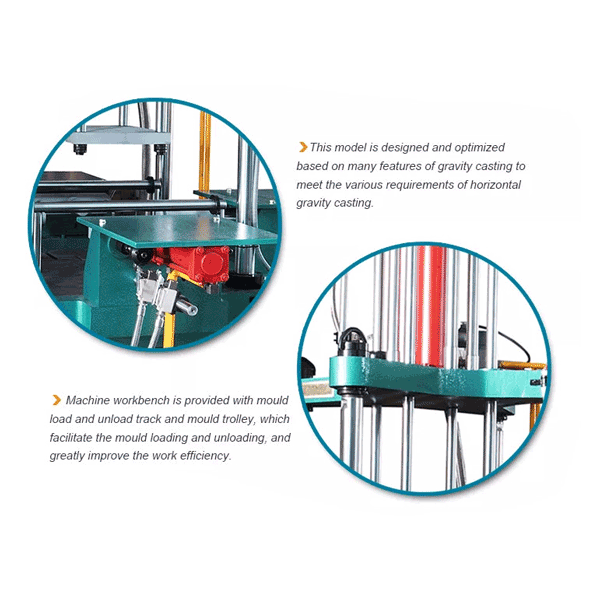

BoQiao's gravity-casting machine features small dimensions, which makes it a great choice for a variety of Mold machine. The BoQiao gravity cast machine's compact design and high-performance make it an ideal choice for various manufacturing environments. Its reliability and value make it a valuable investment for companies looking for reliable casting solutions. It is praised by clients for its consistency in quality, easy operation and maintenance and increased productivity.

Our journey in the field of casting started in 1979 with sale of casting materials and laying the foundation to our industry expertise and market presence Over the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service In 1997 we widened our operations to include the manufacturing of industrial electric furnaces This strategic move allowed us to provide more complete solutions to our customers meeting their growing demands for efficient and reliable heating equipment Our dedication to innovation and quality during this time made us stand out from the rest of the competition landscape By 2002 we expanded our product range by moving into the manufacturing of casting equipment sector This expanded our capabilities to offer a wide range of casting solutions from materials to machinery making sure that our customers could count on us for every aspect of casting We're a trusted business partner due to our extensive experience and knowledge in the casting industry Since our beginning we have remained dedicated to continuous improvement and customer satisfaction which has driven us to evolve and adapt in an Mold machine market