×

×

An interesting and cool method of shaping objects is rotor casting. This is achieved by pouring hot metal into a spinning mold allowing for unique shapes and design features. With the advancement of rotor technology, we do not cast almost like how it is traditionally done

At Rotor, Boqiao Gravity die casting machines we use rotor technology to innovate the way things are made. It used to be when we pour metal into a mold and let it cool, it can take awhile for the piece of metal to harden. The only thing it does is slow everything down. When the mold whirls metal cools, it does so quickly and uniformly. This is really important from the sense that allows us to waste lots less metal during your aging, which saves my family money. It also enables us to create a robust and high-quality product

It is perfect for creating complex shapes that are difficult in most of the other methods. The spinning mold aids the molten metal to attain every aspect of the socket which allows for an replica design. This Boqiao Low Pressure die cast machines then allow us to produce a lot of different options for shapes which would be difficult if not impossible otherwise. It turns out that using rotor casting for titanium or aluminum is a really good idea as well. These metals need to be tough as they are subjected during the casting process, to high heat and spinning.

Any bulk produced product will be identical to the last with rotor technology. We pour at a controlled rate every time and spin the mold constant speed. That way, Boqiao BQ melting furnace we can build a lot of products that are visually consistent and similarly high quality. The process also ensures that rotor casting fills the entire mold, including tiny details so products are perfectly formed with minimal errors. Consistency is crucial in manufacturing, as every output must measure up to the same level of quality.

The rotor casting ensures that it is a lot more productive in comparison to standard methods of throwing. When we work in regular metal casting, then most of the time till steels cool down and goes for next operation that is another process. And, BQ quenching furnace this waiting can take a long time. However, rotor technology cools the metal very quickly and so we could manufacture more products in a shorter time. Budget is well-maintained because no one has to pay extra money for additional time. Of course, the fact that rotor casting is also quite effective for metal recycling in hindsight does save on raw materials which allows its production to be even more cost-effective.

In manufacturing, rotor casting is used in numerous ways. We can manufacture unhindered turbine blades, vital components for airplanes and most beautiful jewellery! No other methods can achieve the same detailed shapes this method is able to create. Rotor casting also Aluminum casting parts makes sure that the end products are produced uniformly, which is essential in critical applications such as aeroplanes and health equipment where safety and reliability are prerequisites.

In Rotor casting, we began our journey in the field of cast iron through the selling of casting components. This was the beginning of our knowledge and presence on the market. Through the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service. In 1997, we widened our business to include manufacturing of industrial electric furnaces. This strategic move enabled us to provide more comprehensive solutions to our customers and meet their growing demand for reliable, efficient heating equipment. Our commitment to innovation as well as the highest quality in this period was a distinct feature from the rest of the competition landscape. By 2002, we further expanded our product range by joining the casting equipment manufacturing sector. This expanded our capabilities to provide a comprehensive array of casting options, from machinery to materials making sure that our customers could count on us for all their casting requirements. Our vast experience and comprehensive understanding of the industry have positioned us as a trusted company for companies looking for top-quality casting equipment and services. Through our long history, we have remained dedicated to continual improvement and customer satisfaction, which has driven us to adapt and grow to a changing marketplace.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Rotor casting customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

BoQiao's gravity-casting machine features small dimensions, which makes it a great choice for a variety of Rotor casting. The BoQiao gravity cast machine's compact design and high-performance make it an ideal choice for various manufacturing environments. Its reliability and value make it a valuable investment for companies looking for reliable casting solutions. It is praised by clients for its consistency in quality, easy operation and maintenance and increased productivity.

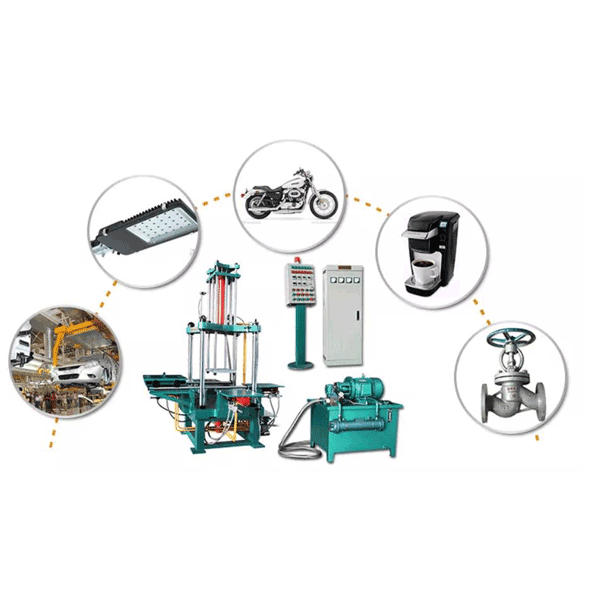

Nanjing BoQiao Machinery Co., Ltd is a Rotor casting, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer our customers all kinds of overall solutions and turnkey projects, including technical consulting, equipment selection mold manufacturing design, process development, operating training, and more. Our products can create an added value for our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.