×

×

Hello, young readers. Ever wonder how some of the items we use every day are made? Pretty interesting, huh? So, Let’s start out our learning today about Die Casting. This is integral to a vast number of industries, as this process creates many components that we interact with every single day. What is Die-Casting When it comes to die casting — Time to Dive in and find the term “die-casting” may not sound familiar to everyone, you might be surprised how big this element of manufacturing can actually be. Die casting, where to parts down very precisely the BOQUIAO process begins by melting one of this specially formulated metal. Then this molten metal is poured in many ways to a specific shape known as the mold. Mold: The mold is the container that assists us to shape our metal work as per the indispensable design. Once the metal cools off and hardens up. We carefully open the mold to remove our finished part as shown in step 6 above It is a very exact process so that every single part produced is identically the same each time.

There are many reasons why die casting is a great way of making parts. First, it is very precise. These molds are built to an extremely fine degree of precision so that each part which is constructed separately from the shrinking metal will be in perfect dimensions. Which is crucial for things like airplanes, meds and cars — where everything has to be just right. The process of die casting offers industries different kinds of advantages. First, it saves money. The process uses materials like aluminum, zinc and magnesium which are relatively less costly. In addition to this, molds can be used several times which further decrease the cost. This means that companies can save money while producing great parts.

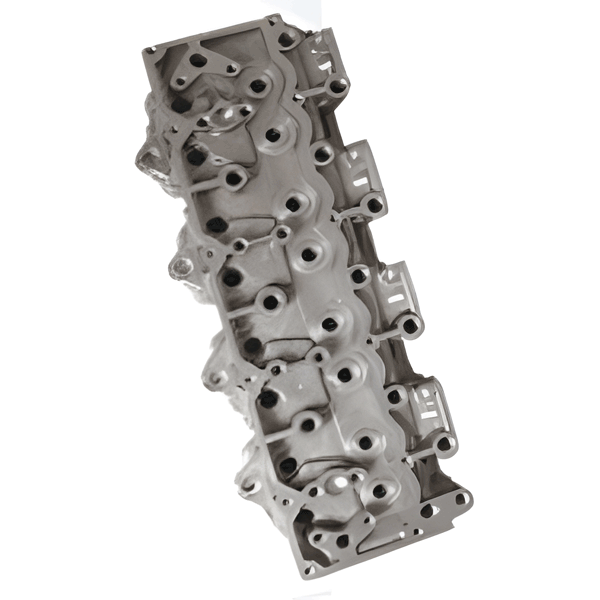

Second, die casting can produce parts or components of any size and shape from the tiniest gears to massive engine blocks. As a result of this range, it is powered by tons of areas including cars and airplanes but also telecommunications which includes everything involving phone and internet technology. Because of this, you find die casting as a preferred choice for making parts.

Last but not least positive aspect about die-casting is that it reduces wastefulness and a greater production efficiency. Not only does it produce less waste than many traditional manufacturing methods, but also with the technology in its early stages of adoption and limited to small-scale production. Moreover, a large number of materials die-cast is recyclable which means less waste reduction. This way, businesses can help take care of the earth and give clean air to all.

Die casting also contributes to the production of more fuel-efficient cars. Cars can be lightened by utilizing lightweight materials like aluminum and magnesium. Less weight equals better fuel economy, and cars go longer between fill-ups. This is environmentally friendly, which can save BOQUIAO energy and drive the vehicle without a wallet.

Parts die casting is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We can provide customers with all kinds of overall solutions as well as turnkey projects that include technical assistance, equipment selection mold manufacturing, process development, operation training and more. Our products can create value for our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Since 1999 we have manufactured and sold more than 2000 units. Parts die casting quality and excellent service make our company enjoy a positive reputation with its customers. The company has shipped its products to Southeast Asia and Africa South America as well as the Middle East. Customers have been very pleased by the quality and services. Customers should be encouraged to create more value.

The BoQiao gravity casting machine has been designed with a compact structure which makes it a Parts die casting for a variety of production environments. Its top-quality performance guarantees an efficient and precise casting while the user-friendly operation simplifies the process of production, allowing operators to achieve optimal outcomes with only minimal training. This versatile machine is extensively utilized across multiple industries, including motorcycle parts, auto parts and electric power fittings as well as engineering equipment. The machine's cost-effectiveness and durability make it an excellent option for companies seeking reliable casting solutions. Customers appreciate the machine's constant high-quality and the ease of its maintenance and operation which minimizes downtime and boosts productivity.

Our journey in the field of casting started in 1979 with sale of casting materials and laying the foundation to our industry expertise and market presence Over the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service In 1997 we widened our operations to include the manufacturing of industrial electric furnaces This strategic move allowed us to provide more complete solutions to our customers meeting their growing demands for efficient and reliable heating equipment Our dedication to innovation and quality during this time made us stand out from the rest of the competition landscape By 2002 we expanded our product range by moving into the manufacturing of casting equipment sector This expanded our capabilities to offer a wide range of casting solutions from materials to machinery making sure that our customers could count on us for every aspect of casting We're a trusted business partner due to our extensive experience and knowledge in the Parts die casting Since our beginning we have remained dedicated to continuous improvement and customer satisfaction which has driven us to evolve and adapt in an ever-changing market