×

×

Az alumínium-gútoló gépek jelentős szerepet játszanak a gyárakban

Fontosak, mert segítenek abban, hogy alumíniumot használjunk különböző tárgyak létrehozására. Az alumínium egy egyedi fém, néhány speciális tulajdonsággal. Ez teszi annyira könnyévé és egyszerűvé a kezelést, de még elegendően erős ahhoz, hogy a anyag hosszú ideig tartson. A cikk megvizsgálja az előnyeit ezeknek a Boqiao alumínium öntőgépek amit ajánlhatunk, és végül azt magyarázzuk, hogyan tervezhető ilyen öntöző aluminium gép a kívánt igényeknek megfelelően, valamint biztonságos működési gyakorlatokkal.

Az öntöző aluminium gépek sokféle előnnyel járulnak. Az egyik legnagyobb előn az, hogy képesek sok terméket gyors sebességgel gyártani. Ez azt jelenti, hogy ugyanazt a terméket egyszerre tömegesen gyártjuk, nem pedig hosszú idő után. Az aluminium szintén könnyű és erős. Emiatt könnyek is, mint ahogy az aluminium magas erősség-súly arányától függ. A disciplináris termékek mindkét tulajdonságot ilyen kombinációban kínálnak, ami fontos azoknak a vásárlóknak, akik addig tartó eszközöket keresnek, amelyek könnyen mozgathatók. Ezek a minőségek teszik az aluminium termékeket alkalmasnak széles körű ipari alkalmazásokra.

Amikor alumínium-öntőgépeket tervezünk, a célokat figyelembe kell venni. Be kell számolnunk azt, hogy milyen típusú termékeket szeretnénk gyártani és mekkora mennyiségben egyszerre. Például, ha rövid idő alatt sok darabot kell gyártanunk, akkor nyilvánvalóan más lesz a tervezet, mint ha csak néhány darabra van szükség. A céljaink és tárgyaink meghatározásával kezdjük el a gép tervezését, amelyre szükség lesz.

Egy kiváló tervezet fontos, mivel ez teszi a gép használatát egyszerűvé és biztonságosabbá. Ez azt jelenti, hogy a gépnek minden szükséges komponensével kell rendelkeznie tökéletes működéshez, és egyetlen gombnyomással lehet be- és kikapcsolni. Emellett új anyagokra is szükségünk van a gép építéséhez. Azokat hosszabb ideig szeretnénk használni, még akkor is, ha nagyobb kihasználtsággal jár a normál használat. Miért szükség van erős gépekre az efficiens termelés érdekében?

Az alumínium ütéses öntése nagyon segíti minket abban, hogy megváltoztassuk az áruk gyártását a gyárakban. Ezek a Boqiao aluminum cast machines engedélyezik nekünk, hogy gyorsan és hatékonyan termeljünk sok darabot egyszerre. Ez azt jelenti, hogy kevesebb idő alatt tudunk több terméket készíteni, ami bármely vállalat számára előnyös. Amikor több terméket gyártunk, akkor kedvezményezett árral tudjuk eladni, mivel minden egyes termékkel kapcsolatos költség csökken.

Legfontosabbabb, hogy az öntőgépek nagyon magas hatékonyságot biztosítanak. Azonban képesek rohamsebességgel (kb. 8 anyagdarab percenként) szolgáltatni, amely lehetővé teszi számunkra, hogy inkább a bolteladásra és a marketingre fókuszáljunk, mint a gyártásra. Az eredmény tökéletes a vállalkozások számára, hiszen már segítette növelni a bevételeiket többszörösen. Ahhoz, hogy egy vállalat jól menjen, több terméket kell eladnia annak érdekében, hogy pénzt kereszen és bővüljön.

Egyaránt nagyon fontos, hogy figyelmesen kövessük az utasításokat a gépek használatakor. Az utasítások megmutatják nekünk, hogyan kapcsolható be és ki a Boqiao, hol kell elhelyezni vagy nem használni, ha helyesen működik, és hogyan tisztítsuk meg, amikor vége van. Ha nem tartjuk be ezeket a szabályokat, a gép meghibásodhat vagy nemfelelően működik. Ez nagy problémát okozna nekünk, mivel javításra lenne szükség, ami pénzt és időt vesz igénybe a termelési időszakaink miatt. Alumínium Ládázó Gép ha nem tartjuk be ezeket a szabályokat, a gép meghibásodhat vagy nemfelelően működik. Ez nagy problémát okozna nekünk, mivel javításra lenne szükség, ami pénzt és időt vesz igénybe a termelési időszakaink miatt.

A BoQiao gravitációs öntőgépe kompakt tervezésű, így kiváló választás számos gyártási környezet számára. Kiemelkedő teljesítménye hatékony és pontos öntést biztosít, míg felhasználóbarát kezelőfelülete leegyszerűsíti a gyártási folyamatot, így a munkavállalók minimális képzés után is optimális eredményeket érhetnek el. Ezt a sokoldalú gépet széles körben használják különféle iparágakban, például motorkerékpár-alkatrészek, autóalkatrészek, alumínium öntőgépek és mérnöki gépek gyártásában. A gép tartóssága és költséghatékonysága értékes berendezési befektetést tesz lehetővé azok számára, akik megbízható öntési megoldásokat keresnek. Ügyfelei különösen értékelik állandó minőségét, könnyű kezelhetőségét és karbantarthatóságát, valamint a növekedett hatékonyságot.

1999 óta cégünk öntött alumínium gépeket gyárt és több mint 2000 darabot adott el. Cégünk kiváló hírnévvel rendelkezik ügyfelei körében megbízhatóságunk, minőségünk és kiváló ügyfélszolgálatunk miatt. Termékeinket nemcsak az ország minden városában és megyéjében értékesítjük, hanem Délkelet-Ázsiában, Afrikában, Dél-Amerikában, a Közel-Keleten és számos más régióban is kínáljuk, ahol nagy sikert arattak ügyfeleink körében. A nyerő–nyerő üzleti modellre, az együttműködésre, az őszinteségre és a becsületességre építve a BoQiao továbbra is a szakmai fejlődés útját követi, folyamatosan javítva termékein és szolgáltatásain, hogy megfeleljen ügyfelei fejlődési igényeinek. Alapvető fontosságú, hogy segítsünk ügyfeleinknek több értéket teremteni.

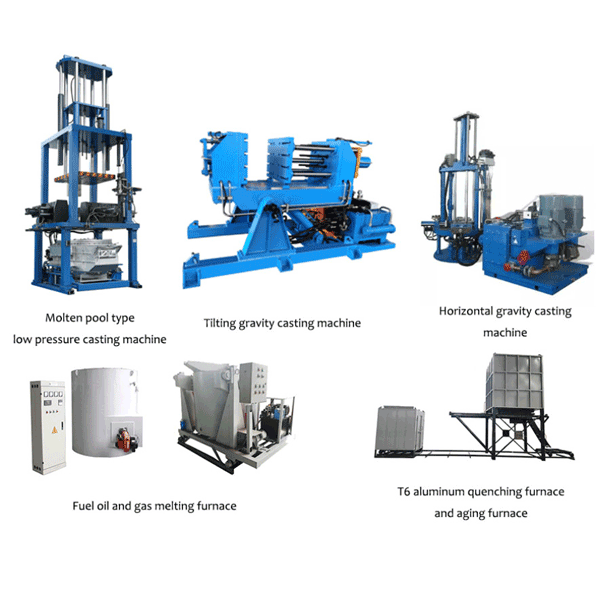

A Nanjing BoQiao Machinery Co., Ltd. egy szakmai tervezési, gyártási és értékesítési vállalat, amely különféle öntőgépeket, hőkezelő berendezéseket és ipari kemencéket gyárt. A jelenleg kínált termékek – többek között a gravitációs öntőgépek, az alacsonynyomású öntőgépek, az olvadókemencék, a lágyítókemencék, a melegítőkemencék, az öregítőkemencék és a transzverzális mágneses kemencék – összesen 18 típust és majdnem 100 féle termékváltozatot foglalnak magukban. Komplex, kulcsrakész megoldásokat kínálunk, amelyek technikai tanácsadást, felszerelés-kiválasztást és gyártást, valamint folyamat-tervezést, továbbá képzést és üzemeltetési támogatást is tartalmaznak. Biztosak vagyunk benne, hogy termékeink értéket teremtenek ügyfeleink számára. A termékek széles körben alkalmazottak a következő területeken: villamosenergia-ipari szerelvények, motorkerékpár-alkatrészek, autóalkatrészek, új energiaforrások, elektronikai és elektromos ipar, nagyfeszültségű kapcsolókészülékek, építőipari gépek, űrkutatási öntvények, ventilátorok, alumíniumöntő gépek és egyéb szakmai öntödei vállalatok.

1979-ben kezdtük el utazásunkat az aluminium öntőgépek területén az öntőanyagok beszerzésével. Ez volt ismereteink és jelenlétünk kezdete a piacon. Évek óta hosszú távú kapcsolatokat építettünk ki ügyfeleinkkel, magas minőségű termékek és kiváló szolgáltatás nyújtásával. 1997-ben bővítettük vállalkozásunkat az ipari elektromos kemencék gyártásával. Ez a stratégiai lépés lehetővé tette számunkra, hogy átfogóbb megoldásokat nyújtsunk ügyfeleinknek, és kielégítsük növekvő igényüket megbízható, hatékony fűtőberendezésekre. Kötelezettségvállalásunk az innováció iránt és a magas minőség iránt ebben az időszakban kiemelkedő helyet biztosított számunkra a versengő piaci környezetben. 2002-re diverzifikáltuk termékpalettánkat az öntőberendezések gyártásának területére való belépéssel. Ez bővítette képességeinket, így teljes körű öntési megoldásokat tudtunk kínálni – az alapanyagoktól a gépeken át – annak érdekében, hogy ügyfeleink minden öntési igényüket biztonságosan ránk bízhassák. Tapasztalatunk és széles körű szakértelemünk a szakmában megbízható szállítóként való elismertséget szereztek számunkra azoknál a vállalatoknál, amelyek legjobb minőségű öntőberendezéseket és szolgáltatásokat keresnek. Mindig elkötelezettek voltunk az ügyfél-elégedettség és a folyamatos fejlődés iránt, ami lehetővé tette számunkra, hogy fejlődjünk és alkalmazkodjunk egy folyamatosan változó piachoz.