×

×

The method of manufacturing metal objects is known as pressure die casting which are just plain fascinating! The process involves pushing very hot molten metal into a mold of specific shape. A mold is a kind of container that the metal fills. After molten metal comes to the solid-state from liquid form which is ready for raw materials in various products. This is often done in many industries, such as car production, aeronautics or electronics. One of the greatest benefits to pressure die casting is that it allows for speedy production rates, saving a good amount of money in manufacturing costs Boqiao Gravity die casting machines is the way to go for many businesses that rely on this process, only because it can be carried out so accurately

While pressure die casting is a useful technique for producing metal parts, it also presents certain disadvantages or constraints. As an example, one issue is that this process may not be the best method to fabricate highly detailed designs with a high level of intricacy. While there are several merits of pressure die casting, one such benefit is the reason why it remains a popular choice:

With a lot of change in the technology, pressure die casting are getting all more well equipped with every passing day. Most manufacturers are consistently trying to innovate the process, making it faster and more accurate. This underscores the potential of vacuum-assisted high-pressure die casting, one innovative process being worked on. This means the mold can be evacuated even faster, which results in quicker production speed and higher detail of parts. Moreover, this process makes the casting portion less wastier in material

One of the most crucial enhancements in Boqiao Low Pressure die cast machines technology has been the introduction and implementation of computer-aided design (CAD) software. This software enables manufacturers to build up intricate designs of parts and even test for possible defects pre-final casting. As a result, much time should be saved in the process overall to reduce errors and improve the quality of final goods.

Among them Aluminum which is lightweight material and has good mechanical properties. It is used in a wide range of applications and when we speak about composite materials, Boqiao Aluminum casting parts is mostly associated with the automotive backlight housing/road siden-fender otherwise known simply as car parts and aerospace field because of some very nice features it possess.

Here Are Different Types Of Metals Used For Pressure Die Casting With Some Specific Features: Zinc: As It Melts At A Lower Temperature Which Makes This Metal More Comfortable To Mold Therefore, The Use Of Zinc Is Popular In Pressure Die Casting. Moreover, highly corrosion-resistant zinc is also suited to a wide range of applications.

Aerospace industry: Pressure die casting is being used to an Electronics Industry : for the electronics sector, pressure die casting, Storage compartment can be made parts like Heat sinks、LED house type fins and computer components. So far as this subject is concerned, yes you need to have high precision.

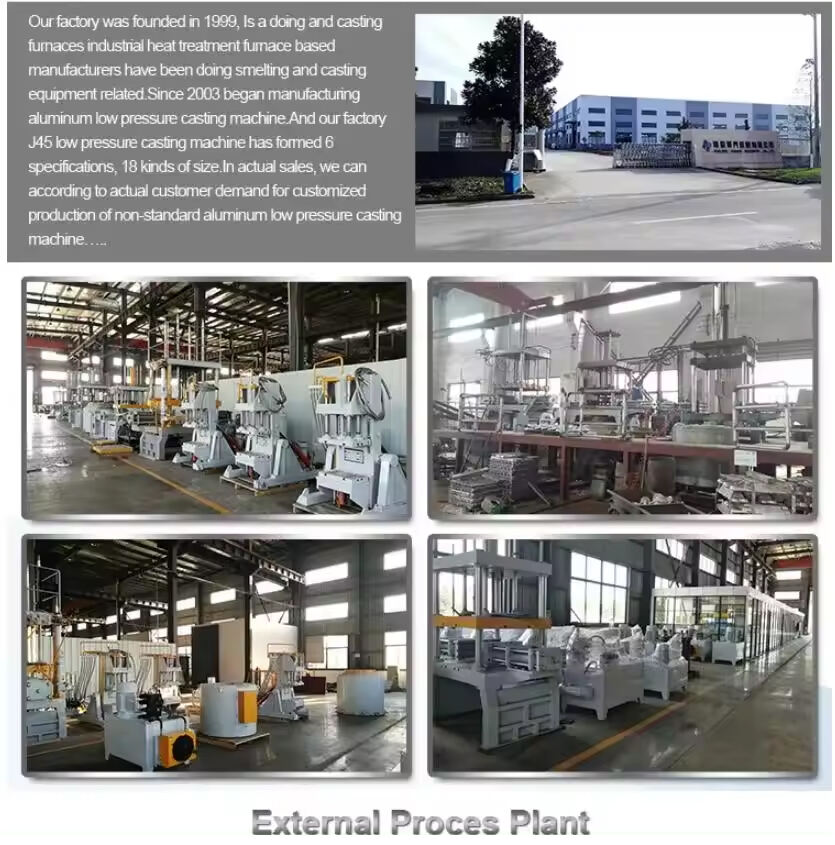

Our journey in the field of casting started in 1979 with sale of casting materials and laying the foundation to our industry expertise and market presence Over the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service In 1997 we widened our operations to include the manufacturing of industrial electric furnaces This strategic move allowed us to provide more complete solutions to our customers meeting their growing demands for efficient and reliable heating equipment Our dedication to innovation and quality during this time made us stand out from the rest of the competition landscape By 2002 we expanded our product range by moving into the manufacturing of casting equipment sector This expanded our capabilities to offer a wide range of casting solutions from materials to machinery making sure that our customers could count on us for every aspect of casting We're a trusted business partner due to our extensive experience and knowledge in the casting industry Since our beginning we have remained dedicated to continuous improvement and customer satisfaction which has driven us to evolve and adapt in an Pressure die market

BoQiao's gravity cast machine is a compact design, which makes it a good choice for a range of manufacturing settings. The Pressure die of the machine ensures accurate and efficient casting while its user-friendly system simplifies the production process, which allows users to get the best outcomes with only minimal training. This multi-purpose machine is used in a variety of industries, such as motorcycle parts automobile parts and electric power fittings as well as engineering equipment. The durability and affordability are a great investment for businesses seeking solid casting solutions. The machine is highly regarded by customers for its consistent high-quality, simple operating and maintenance, and the increased production.

Since 1999 the company has produced and sold more than 2, 000 units. BoQiao has Pressure die a good reputation with customers because of our reliable quality and excellent customer service. Apart from sales in all cities and provinces across the nation Our products have also been sold to Southeast Asia, Africa South America, Middle East and many other locations, and have been a great success by customers. Based on the business ethos of cooperation and win-win, integrity and honesty, BoQiao will continue to follow the path of professional growth and continually improve its products and services to better meet the demands of customers. Customers must be helped to create more value.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly Pressure die of product specifications. We provide a variety of turnkey services, which includes technical assistance, equipment selection and manufacturing and process design, as well as training and operating. We can help our products bring value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.