×

×

Die Casting is special way to manufacture some metal items which we use in our dayykosmetische.. Think of it like pouring molten metal carefully into a mold. Think of a mold like a special shape or container that is made to look exactly the same as something small, all the way up through large. This Boqiao Gravity die casting machines process allows us to create a plethora of items made from metal, including car parts, toys and ornate jewellery! Do you know what injection mold die casting can do that is really useful for a lot of manufacturers out there?

Injection mold die casting is a popular engineering process that manufacturers utilize, and they tend to do it quite often. Another big one being it is a fairly quick process for them, and they can produce product faster with this method. Boqiao Low Pressure die cast machines can do this, in turn creating multiple products simultaneously. It means that they can get their work onto the market for cheaper and faster than on other projects. By making all this stuff together they also get to spend less per unit, which is a huge benefit. Moreover, the accuracy of injection mold die casting is very high so that accurate parts can be produced in a manner they are designed together.

Injection mould die casting ensures that all products and technology are manufactured with extreme clarity within the molds. It will also enable repeatable format, and produce parts that are dimensionally accurate to within tolerances. Similar products all fit together correctly and interoperate well, resulting in exactly what we want. A second reason why items made in this way end up of such high quality, is again due to the fact that along with it all being metal, Boqiao Aluminum casting parts has been heated until glowing and red hot. When the metal is hot, its viscosity decreases and can even fill in completely. By doing this we make sure that there are no holes/gaps in the output and everything looks perfect.

The selection of the material is very important in injection mold die casting. Since the on hand materials have different properties, this means they behave in a certain way and suiting for specific product outcome. Take zinc, for example: It's a great material to create small products that require ubiquity — toys would be an excellent candidate because it is light and malleable. Conversely, aluminum is an ideal material for the production of car parts seeing that it provides both strength and lightness. When manufacturers choose a material for their products, the decision about what to use depends on different properties of each one and those making them have to scout across various factors such as which would be BETTER for this or that.

Injection mold die casting starts with the inception of mould and The manufacturer then produces a mold that is identical to what they want the end product to be like. This is a tough metal (tool steel) able to withstand the high temperatures and pressures of the process without transferring heat too quickly, thus allows time for cooling. Next, it is time to manufacture the product now that your mold is ready. In the case of injection mold die casting, what happens is that a certain metal used to manufacture an article is heated until it reaches incandescent temperatures. It is poured in to a mold via specialized machines at an appropriate hot temperature. Now this machine is huge and without it, because the metal has to b poured in a mold evenly, so all products come right. Once the metal has cooled, it is gently removed when you open up your mold and voila!

Injection mold die cast journey into the field of casting began in 1979 with selling of casting material that laid the groundwork to our industry expertise as well as our market position. We've established lasting relationships with clients over the years by offering high-quality products, and providing exceptional service. In 1997, we grew to include the manufacturing of industrial electric heaters. This was a smart move that enabled us to offer more comprehensive solutions for our clients and satisfy their increasing demand for efficient, reliable heating equipment. Our determination to provide quality and innovation set us apart from the crowd. In 2002, we'd diversified our offerings by introducing the production of casting equipment. This expansion allowed us to provide a comprehensive array of casting options, from equipment to materials, ensuring that our clients can rely on us for everything they require in casting. We have earned the reputation of a reliable business partner because of our extensive experience and knowledge in the casting industry. Throughout our history, we have remained dedicated to constant improvement and customer satisfaction, which drives us to grow and change to a changing marketplace.

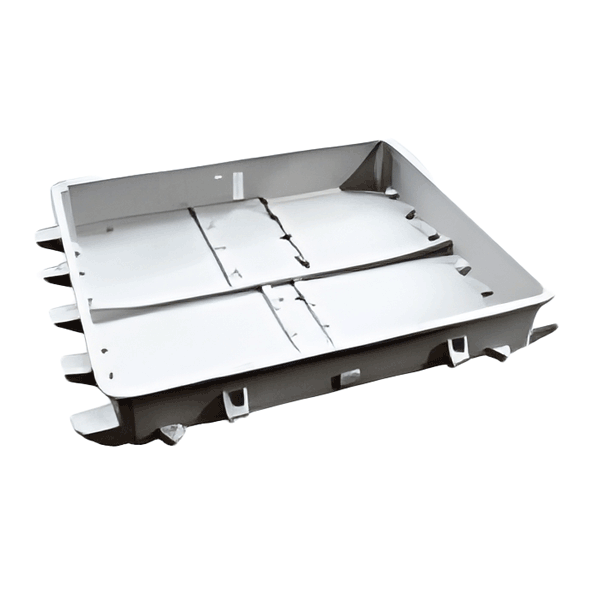

The BoQiao gravity casting machine is Injection mold die cast with a small structure and is a perfect choice for various production environments. Its high-performance makes for accurate and efficient casting and the user-friendly design makes the production process, allowing operators to attain the highest quality outcomes with only minimal training. This multi-purpose machine is used in a variety of sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it an investment worth making for companies looking for reliable casting solutions. It is praised by customers for its dependable quality, easy operation and maintenance and increased production.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include technical advice, equipment selection and manufacturing and process design, as well as training and operations. We are confident that our products will create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, Injection mold die cast and other professional castings production enterprises.

Injection mold die cast company has sold and manufactured more than 2, 000 units from 1999. Reliable quality and excellent service make our company enjoy a positive reputation with customers. In addition to selling in every city and province across the country our products have been shipped to Southeast Asia, Africa South America, Middle East and various other countries and are well-received by customers. Based on the business philosophy of win-win and cooperation, honesty and sincerity, BoQiao will continue to follow the path of professional growth and continually improve its products and services to better meet the needs of its customers. Customers need to be assisted in helping make more money.