×

×

The bit that sits on top of an engine is a massive chunk, and it got its name be the cylinder head. This is an incredibly critical portion to make sure the engine both functions properly and also uses its fuel efficiently. The Boqiao cylinder head itself is produced in a process called Cylinder Head manufacturing; it consists of several layers.

Cylinder heads are one type of a kind which can be made with the process called casting. This Gravity die casting machines is called casting upon which you shall mould the Cylinder head shape. Sit back, the very first and foremost you would require an outline/model of a desirable shape in which it is to be made. These patterns are referred some times as pattern of a model. When you have the pattern with you, a sand or any other shape-retaining material is used to create a mold. Molds are typically done in 2 halves as this makes removing your pattern a breeze once you want to do mostly.

The first step, after the mold has been made ready for it is its casting. The process of this includes heating up a metal until the point it is hot enough liquify which them becomes molten metal. At last, the mold is filled with liquid metal. Hot metal is then poured into the mold and fills it, molding itself to match. The Boqiao metal is then allowed to cool and harden. Then comes the fun part of carefully popping the cylinder head out. But it is not completely done either as there are some key steps left to go before we can wrap up the cylinder head!

One of the methods is sand casting due to its practical process. Mold for sand casting made up of. Sand casting — A versatile method that allows the sand to be molded into any shape. This Low Pressure die cast machines method is ideally suited for the manufacture of parts with intricate shapes, a category that includes steel casings.

Aluminum is one of the Boqiao most common materials used when modifying cylinder heads. Aluminium is a popular material used here because of their BQ melting furnace light weight and strength, making them great for the job. Take note that depending on the type of engine aluminum can carry heat also much quicker as compared to iron from a cylinder head design or an engine.

Cylinder heads are extremely sophisticated, technical components that call for no less than exact and scientific craftsmanship. One critical aspect in this entire process is understanding behavior of the metal after it has given chance to cool once poured into mold. This BQ quenching furnace is really important because the rate at which metal cools can change how strong, or even waterproof a final item turns out.

To make a competition head you have to pay attention in many points. This Aluminum casting parts can involve the metal you are utilizing, just how your mold is configured and also what happens to once that molten liquid hardens.

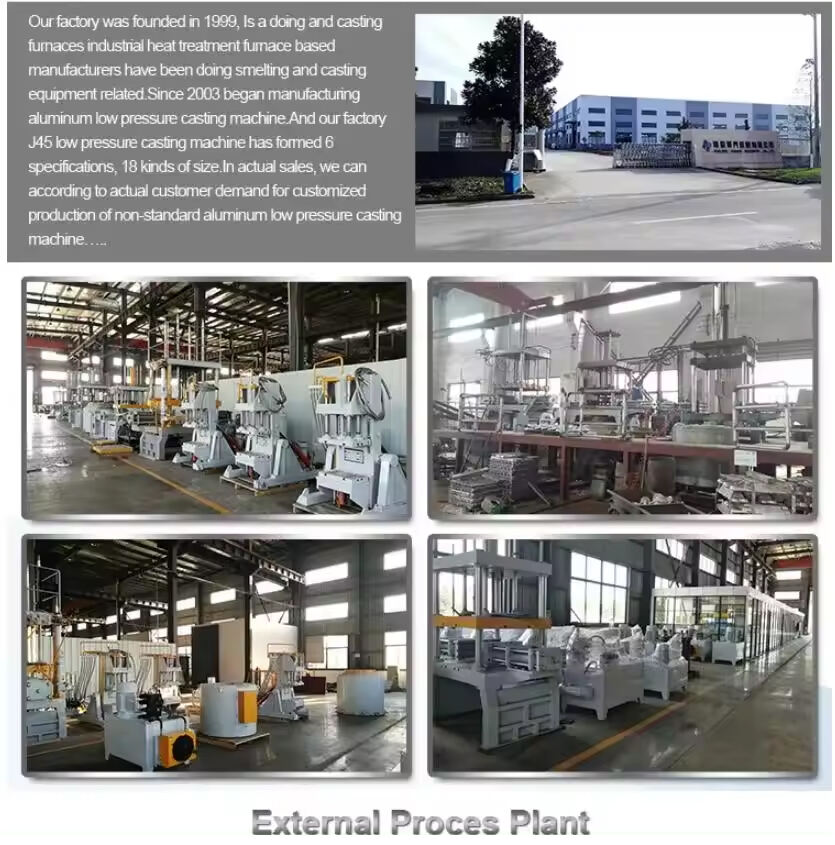

Since 1999 we have manufactured and sold more than 2000 units. Cylinder head casting quality and excellent service make our company enjoy a positive reputation with its customers. The company has shipped its products to Southeast Asia and Africa South America as well as the Middle East. Customers have been very pleased by the quality and services. Customers should be encouraged to create more value.

The BoQiao Cylinder head casting is designed with a compact structure which makes it a great option for various manufacturing environments. Its top-quality performance guarantees efficient and precise casting, and its user-friendly interface makes the process of production, allowing users to get the best results with little training. This multifaceted machine is widely utilized across multiple sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its low cost and long-lasting capabilities make it an excellent choice for companies that are looking for solid casting solutions. Customers appreciate the machine's consistent quality and the convenience of its operation and maintenance that reduces downtime and enhances productivity.

Cylinder head casting journey into the field of casting began in 1979 with selling of casting material that laid the groundwork to our industry expertise as well as our market position. We've established lasting relationships with clients over the years by offering high-quality products, and providing exceptional service. In 1997, we grew to include the manufacturing of industrial electric heaters. This was a smart move that enabled us to offer more comprehensive solutions for our clients and satisfy their increasing demand for efficient, reliable heating equipment. Our determination to provide quality and innovation set us apart from the crowd. In 2002, we'd diversified our offerings by introducing the production of casting equipment. This expansion allowed us to provide a comprehensive array of casting options, from equipment to materials, ensuring that our clients can rely on us for everything they require in casting. We have earned the reputation of a reliable business partner because of our extensive experience and knowledge in the casting industry. Throughout our history, we have remained dedicated to constant improvement and customer satisfaction, which drives us to grow and change to a changing marketplace.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, Cylinder head casting and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include the technical support, selection of equipment and manufacturing processes, design, training and operations. Our products can create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.