×

×

Creating custom shapes for plastic products requires a lot of finesse, focus, and attention to detail. We call these shapes moulds and they are essential to create all sorts of plastic item by injecting liquid synthetic material into them. So, the moulds of Products from Boqiao need to be created with a lot of precision and well thought out prior as plastics that are formed from here have good finishing.

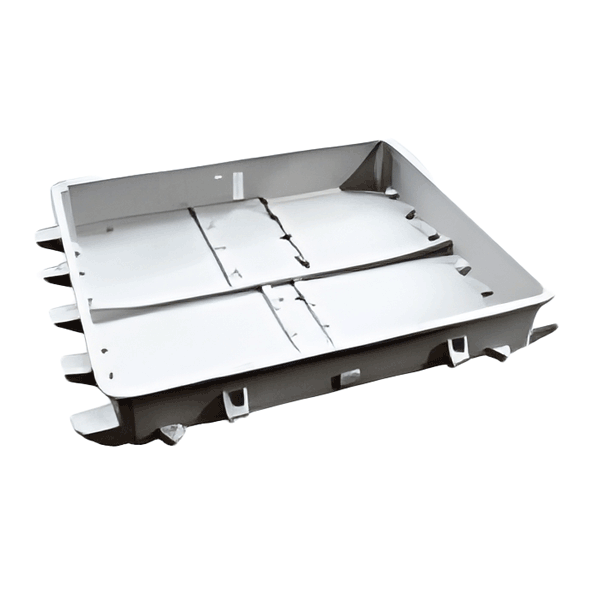

Once the design is finalized and approved its routed to mould making department. The use a high-tech machine that can cut metal practically perfectly to form the mould from steel or aluminum in this aides departments. With the precision of a jeweller, robot arms form metal into what will become mould cavities for plastic. Upon the completion of mould like Gravity die casting machines from Boqiao, it is polished and final touch up to ensure it look good as well other things.

Mould design is crucial for high-volume, mass patterns making efficiently. This can lead to either increased or decreased production time, depending on how many shapes are in the mould and whereabout plastic enters it. The more shapes, or cavities in the mould like Low Pressure die cast machines from Boqiao, there are, lesser time it takes to produce and that only helps speed up production.

The rate at which plastic enters the mould, and how it cools ultimately determine any number of other variables that dictate whether or not things can be made more quickly. All these things are necessary in place to make sure that everything works flawless and runs fine. Proper mould design like Aluminum casting parts can help cut down plastic product production time and costs.

Making moulds is a kind of balance between skill, art, and technical knowledge. It’s almost like combining math and arts! You have to know how plastic behaves by moving and solidifying, while at the same time the mould may have a very complex and detailed design. The skill comes from balancing these two. You need good focus and precision to make sure every detail is where it should be. In the end, everything comes together when the product is removed from the mould like BQ melting furnace, showing you how smart the mould maker is.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Injection mould making customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

In Injection mould making, we began our journey in the field of cast iron through the selling of casting components. This was the beginning of our knowledge and presence on the market. Through the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service. In 1997, we widened our business to include manufacturing of industrial electric furnaces. This strategic move enabled us to provide more comprehensive solutions to our customers and meet their growing demand for reliable, efficient heating equipment. Our commitment to innovation as well as the highest quality in this period was a distinct feature from the rest of the competition landscape. By 2002, we further expanded our product range by joining the casting equipment manufacturing sector. This expanded our capabilities to provide a comprehensive array of casting options, from machinery to materials making sure that our customers could count on us for all their casting requirements. Our vast experience and comprehensive understanding of the industry have positioned us as a trusted company for companies looking for top-quality casting equipment and services. Through our long history, we have remained dedicated to continual improvement and customer satisfaction, which has driven us to adapt and grow to a changing marketplace.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, Injection mould making manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We are able to provide customers with all kinds of overall solutions and turnkey projects including technical consultation, equipment selection, mold manufacturing and process development, operation training and so on. Let our products add the value our customers need. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

The BoQiao gravity casting machine is Injection mould making with a small structure and is a perfect choice for various production environments. Its high-performance makes for accurate and efficient casting and the user-friendly design makes the production process, allowing operators to attain the highest quality outcomes with only minimal training. This multi-purpose machine is used in a variety of sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it an investment worth making for companies looking for reliable casting solutions. It is praised by customers for its dependable quality, easy operation and maintenance and increased production.