×

×

You may have seen a shiny metal object such as an automotive part or perhaps even a toy, and wondered how it was produced. Also: this could also be metal mold casting. This is an unusual technique in which melted liquid metal gets poured into a hollow shape, or mold, to create a physical 3D object that we can touch and feel. This process is simply amazing and it produces many of the things we see every day.

Most importantly, how is a mold made. A mold works much like a container with the same shape as this final icing. It can be fabricated from materials such as sand, ceramics or metals. The mold typically contains two parts (top and bottom). These two halves nestle into each other to define the cavity within the mold in which liquid metal will reside. The Boqiao Gravity die casting machines mold must be designed well; after all, full page prints we need is to get an exact reproduction of the item.

Ok now the fun part, heating up the metal. Metal is that it can be melted and become molten, by heating up the metal to this state at which your looks glowing liquid. Once the metal is melted, it has to be poured very carefully into a mould through a designed opening channel called sprue. The sprue is a tiny channel that the molten metal flows down to fill in the area within the mold. The molten metal that enters this space is constrained by the wall of hot, though solidifying mold. After the hot metal poured in, it hardens and begins to cool off returning into a solid.

If the Boqiao metal cools too fast, it will grow brittle and run little risk of snapping versus when this process occurs very quickly, you can cool brittle reduces; while in low temperatures with minimal deformation being possible. In contrast, if the metal cools too slowly it may not solidify well which can also result in imperfections or issues with the end product. So, the cooling process must be controlled well to keep in consideration that we want the metal object at hand to come out as strong and useful.

Although a longer process than sand casting, metal mold casting is commonly used when there are substantially more units to be produced. The mold creation process is so extensive that when a Lithophane sculptor has the perfect molds, they can crank out as many identical pieces of work without needing to create new molds. This Boqiao BQ melting furnace is perfect for businesses who need to manufacture a lot of metal parts like companies in the car industry or that build appliances.

Versatility is another pro of metal mold casting. The way to using this process there can be variety of shapes and sizes. Some products implemented with very difficult design, it still can be integrate few molds together to form final item. Plus, Low Pressure die cast machines is simple to alter the size of final object by merely changing mould cavity dimensions which gives a good range for manufacturers in terms pf products from big-to-small.

Metal mold casting is not something new and has been for years, but the efficiency of metal plastic injection molding (from my information) has been greatly improved in modern manufacturing world. With new technologies like CAD,(computer-aided design) engineers can create molds that are so precise, (instead of roughly the right size as they may have 25 years ago,) these one develop using lay up and curing. This Aluminum casting parts allows for the molds to be made very precisely which enable less material wastage and high-quality metal parts.

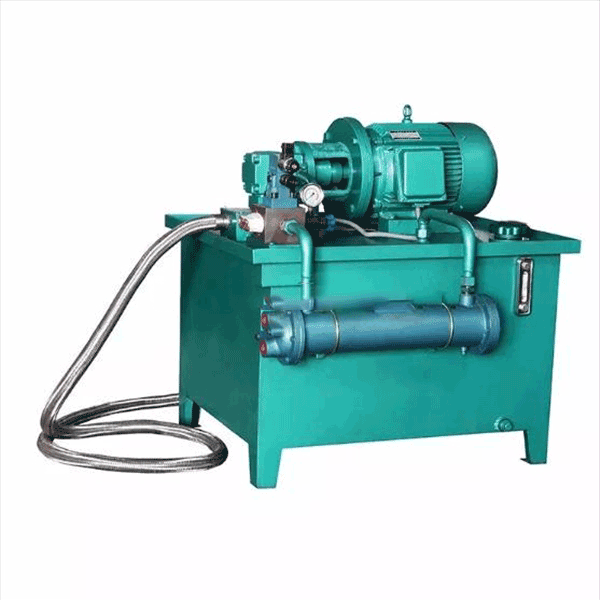

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various Metal mold casting, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer customers all kinds of overall solutions and turnkey project services, such as technical consultation, equipment selection, mold manufacturing design, process development as well as operation training and much more. We are confident that our products will create value to our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our journey into the field of casting began in 1979 with sales of casting materials that laid the groundwork for our experience as well as our market position Over the years we have built lasting relationships with our clients through offering high-quality products and excellent service In 1997 we expanded our services to include manufacturing of electric furnaces for industrial use This move was a strategic one that allowed us to offer more complete solutions for our clients and satisfy their increasing demand for high-quality reliable heating equipment At this point our commitment to quality and innovative thinking made us stand out from the competition In Metal mold casting we had further expanded into the manufacture of casting machines We were able to provide the full spectrum of solutions for casting including the materials as well as machinery This enabled us to become a one-stop store for our customers with casting needs Our experience and extensive knowledge of the industry has made us a reliable partner for businesses seeking top-notch casting equipment and services We've always been devoted to customer satisfaction and continuous advancement This has driven us to evolve and adapt in a marketplace that is ever-changing

BoQiao's gravity-casting machine Metal mold casting small dimensions, which makes it a good choice for many manufacturing settings. The BoQiao gravity cast machine's compact design and top-quality performance make it an ideal option for a variety of manufacturing settings. Its low cost and long-lasting capabilities make it an excellent investment for companies looking for solid casting solutions. The machine is highly regarded by its customers due to its constant high-quality, simple operation and maintenance and increased efficiency.

Our firm has sold and manufactured over 2, 000 units in the last year. Metal mold casting and reliability make our company have a good reputation with customers. Apart from sales in every city and province across the country Our products have also been shipped to Southeast Asia, Africa South America, Middle East and many other locations and have been a great success by customers. Based on the business ethos of cooperation and win-win, sincerity and honesty, BoQiao will continue to follow the path of professional growth and continuously improve products and services to meet the demands of customers. The need to assist customers in creating more value.