×

×

Hello, young readers! Do you ever wonder how great things such as cars, toys and appliances are manufactured? Really interesting, huh? The Casting process & Foundry are one very important ways to make products. In this post, we will be looking into the exact working of these processes and why are they so important. Let’s find out more together

Every new creation starts with an idea! In other words, Boqiao Gravity die casting machines somebody has an idea for something they want to build. It could be anything, a new toy or a nice flashy car. Then they normally sketch an image or create a pattern of how it will look in the end. This is an important drawing because it gives everyone a sense for the end result.

Metal Casting: Metal casting is an essential part of the casting process. It is exactly as what it sounds like, numerous types of metals form assorted parts. The process of pouring hot melted metal into a mold to create an object from that specific shape is known as Metal Casting. This is similar to baking a cake! The mold functions as our baking pan and the molten metal is poured out like cake batter

Hence metal casting, Boqiao Low Pressure die cast machines there is several kind of it! For instance, in sand casting mold would be made from the sand. It is building a sandcastle but with metal instead of water! Rather than using sand, investment casting involves a wax shape. It is a different way in the creation of the end product.

To produce castings in a foundry specific steps have to be followed. The metal has to be melted down into a liquid in the first place Next, Boqiao BQ melting furnace it is poured very carefully into the mold that forms it to particular design. The finished metal part is released after the now liquid will have cooled and become solid. This is an exciting part because it shows what we have created!

With the improvement in technology, processes of casting and foundry are becoming better. As an example, there are special machines today that rapidly produce moulds. Cause this really saves a lot of time and effort. This BQ quenching furnace is making the development of products easier and instantly deploying new product.

So, that’s it! Casting and foundry plants are quite an important service as they make many other functional products that we see all around us. This Aluminum casting parts is a quiet and scientific sport(RuntimeObjectfollow LINK). From the inception of an idea to a beautiful creation processes like these help in producing large scale things that average people use everyday.

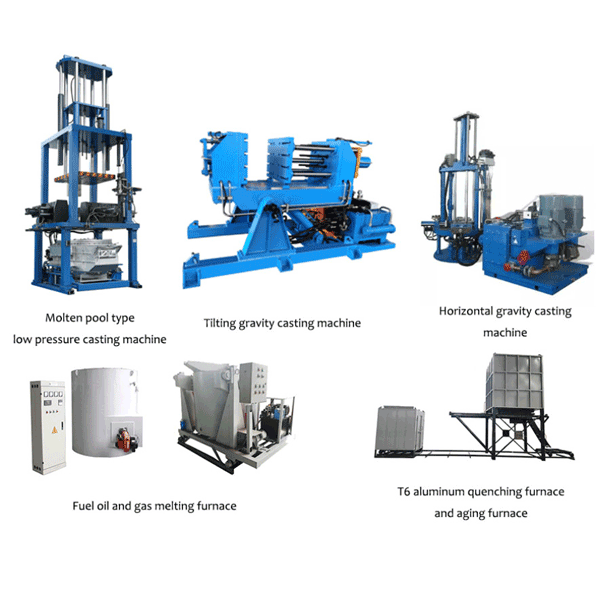

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include technical advice, equipment selection and manufacturing and process design, as well as training and operations. We are confident that our products will create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, Casting and foundry and other professional castings production enterprises.

The BoQiao Casting and foundry is designed with a compact structure which makes it a great option for various manufacturing environments. Its top-quality performance guarantees efficient and precise casting, and its user-friendly interface makes the process of production, allowing users to get the best results with little training. This multifaceted machine is widely utilized across multiple sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its low cost and long-lasting capabilities make it an excellent choice for companies that are looking for solid casting solutions. Customers appreciate the machine's consistent quality and the convenience of its operation and maintenance that reduces downtime and enhances productivity.

Casting and foundry journey into the field of casting began in 1979 with selling of casting material that laid the groundwork to our industry expertise as well as our market position. We've established lasting relationships with clients over the years by offering high-quality products, and providing exceptional service. In 1997, we grew to include the manufacturing of industrial electric heaters. This was a smart move that enabled us to offer more comprehensive solutions for our clients and satisfy their increasing demand for efficient, reliable heating equipment. Our determination to provide quality and innovation set us apart from the crowd. In 2002, we'd diversified our offerings by introducing the production of casting equipment. This expansion allowed us to provide a comprehensive array of casting options, from equipment to materials, ensuring that our clients can rely on us for everything they require in casting. We have earned the reputation of a reliable business partner because of our extensive experience and knowledge in the casting industry. Throughout our history, we have remained dedicated to constant improvement and customer satisfaction, which drives us to grow and change to a changing marketplace.

Since Casting and foundry the company has produced and sold more than 2 000 units. Excellent service and reliable quality make our company enjoy a positive reputation with clients. In addition to selling in every city and province across the country The company's products have been shipped to Southeast Asia, Africa South America, Middle East and many other locations and have been a great success by customers. Based on the premise of win-win and cooperation, sincerity and honesty, BoQiao will continue to take the road of professional development and continuously improve products and services to better meet the demands of customers. Need to help customers create greater value.