×

×

Hey kids! Do you know what happens when we heat aluminum? Well, guess what? It melts! That’s right! Above a certain temperature, aluminum is no longer solid but instead becomes molten. This melted aluminum is really awesome since you can use it to make spectacular shapes and designs. Today, we are going to tell you how it is possible to melt aluminum safely and what kind of interesting things can be made from these materials

DISCLAIMER So before we start melting aluminum, it is essential that SAFETY comes first. Wear your gloves to protect yourself and a heat-proof apron to save your clothes. We also need a source of heat — it could be a furnace or propane torch. Finally —the mold or container This Boqiao Aluminum casting parts is where the melted aluminum will go when done.

Now, lets see what steps we have to be followed for aluminium melting? THE FIRST THING YOU HAVE TO DO IS CLEAN ANY ALUMINIM PIECE THAT YOU MAY MIGHT BE WORK HAVING. These should be free of dirt or any oil. Why? You will need to rinse the aluminum of any cooking oils as overtime these can create black deposits at un-even temperatures when melting your metal

Or you will have to fill a furnace with charcoal, if using Boqiao Low Pressure die cast machines. You simply light it with a match Men Style Fashion Once the charcoal is really hot, you can drop those aluminum pieces into a specialized metal container (called a crucible). Then place the crucible inside the furnace. The aluminum will be heated and turn to liquid from the heat!

Alternatively, you will place the aluminum pieces in a metal container if youre using a propane torch Apply the torch flame to your container. Be sure to slowly positioning the container around. This Boqiao Gravity die casting machines helps the aluminum melt even better, so be careful! 6. You would not want to hold it anywhere near the flame because that is a good way for a fire to start, and fires are most definitely bad!

Is it a surprise that aluminum is exhibiting this kind of behavior, when compared to other metals with much higher melting points? This means it has the property to melt on a very low temperature that makes it convenient to use. Aluminum Melts at 1,220 ° F (660° C) Then, we get to do something really fun — melt the aluminum! The liquid aluminum can then be poured into a mold or cast to make something new When the molten liquid aluminum cools it will return to a solid state, in whatever form of mold we poured it into.

Another cool idea is to give lost wax a try. This is such a great process! You start by making a model in wax of the shape you want. Next, the wax model is coated with ceramic and left to dry. Afterward, the ceramics are dried before being put inside a furnace meant to melt away the wax. Once the wax has gone, we now have an empty place of where is was and that space can be filled with molten aluminium to get a fresh new part!

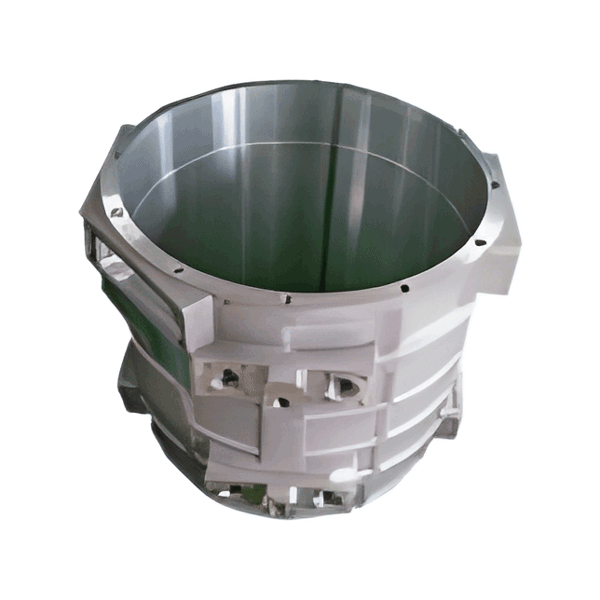

BoQiao's Gravity Casting Machine has a compact design, which makes it a good choice for many manufacturing settings. Its superior performance ensures efficient and precise casting, and its user-friendly interface makes the production process, allowing operators to achieve optimal results with little training. This multifaceted machine is widely used in a variety of industries, including motorcycle components auto parts, auto parts, Melting aluminum for casting, and engineering machinery. The durability and affordability make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by its customers due to its constant quality, ease of operating and maintenance, and the increased efficiency.

In 1979 we started our journey in the industry of cast iron with the purchase of casting materials This was the beginning of our experience and our presence on the market We've established lasting relationships with our clients over the years offering top-quality products and offering exceptional customer service In 1997 we expanded to include the manufacturing of industrial electric heaters This move was a strategic one that allowed us to provide more complete solutions to our clients addressing their growing demands for efficient and reliable heating equipment Our determination to provide quality and innovation distinguished us from the competition By 2002 we'd further diversified our offerings by introducing the production of casting machines This expansion allowed us to offer a wide array of casting options from materials to machinery and ensure that our customers could rely on us for all their casting needs Our vast experience and comprehensive understanding of the industry have established us as a trusted company for companies looking for top-quality casting equipment and support Since our beginning we've remained committed to continuous improvement and client satisfaction which drives us to change and evolve to the ever-changing Melting aluminum for casting

Our company has sold and made over Melting aluminum for casting units since 1999. Excellent service and reliable quality make our company have a good reputation with its customers. The company has sold its products to Southeast Asia and Africa South America as well as the Middle East. Customers have also been satisfied with the service and quality. Customers should be encouraged to create more value.

Melting aluminum for casting is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We can provide customers with all kinds of overall solutions as well as turnkey projects that include technical assistance, equipment selection mold manufacturing, process development, operation training and more. Our products can create value for our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.