×

×

Mold sand casting — a unique and exciting process of making various objects from metal or any other materials. This is a method that applied in factories, where they manufacture several products. In this article we will thoroughly discuss about what mold sand casting is, how it works and the core benefits of using them along with different materials used in mold sand casting today.

Mold sand casting is the process of pouring a molten metal or other material into an area formed by sand, same with the Boqiao Gravity die casting machines. As the object cools, also to become hard, a sin favoured bond shape in it between gaps of sand to maintain its formation. Think of it as building a sandcastle on the beach. Add water to the sand, it becomes wet and keeps its form as does the shape of an object cast in this sand.

In common with jewelry casting, you begin making something utilizing mold sand castings The process involved in this starting with a pattern of the object you wish to make. Pattem is made from some sort of product like wood or plastic. Once you have the pattern, it is rammed into sand to make a mold that copies the shape of object.

After the mold is prepared/created, it must be filled with a hot substance like molten metal or another superheated material, just like the Boqiao Low Pressure die cast machines. This step is hot and can cause the material to burn so be very careful. In this cases, the material is melted and then allowed to cool in its final form of a mold. This cooling step is critical because it permits the material to cool and harden into the exact shape of that mold. This is how it works: After your object has cooled completely, you can destroy the mold and retrieve the finished piece. But the beauty in this process is that we can recycle and make molds again with same sand

Mold sand casting is something good and bad both, along with the Boqiao BQ melting furnace. The only good thing is that this technique can be used to manufacture many things. You can craft everything from nuts and bolts to large-scale industrial machines for use in factories etc. It is also a pretty basic and relatively cheap way to make things which makes it quite popular with factories.

But also there are some cons. That mold takes time — and thousands of individual teeth shaving content from the primary piece to finalize its negative like BQ quenching furnace. Making the mold is not easy and it demands attention to detail. Also, sometimes the process of sand may finish it with a defected surface or other imperfections that you do not want to make in some products.

This process also enables the crafting of intricate shapes that would be arduous (if not outright impossible) to make using other means of Aluminum casting parts. The mold sand casting can assist you do this, as an example — if you'd such according to bear a severed alongside problematic or steep clinics etc. It can also be used to make numerous number of the same object, and this is very important for businesses that require their parts in quantity.

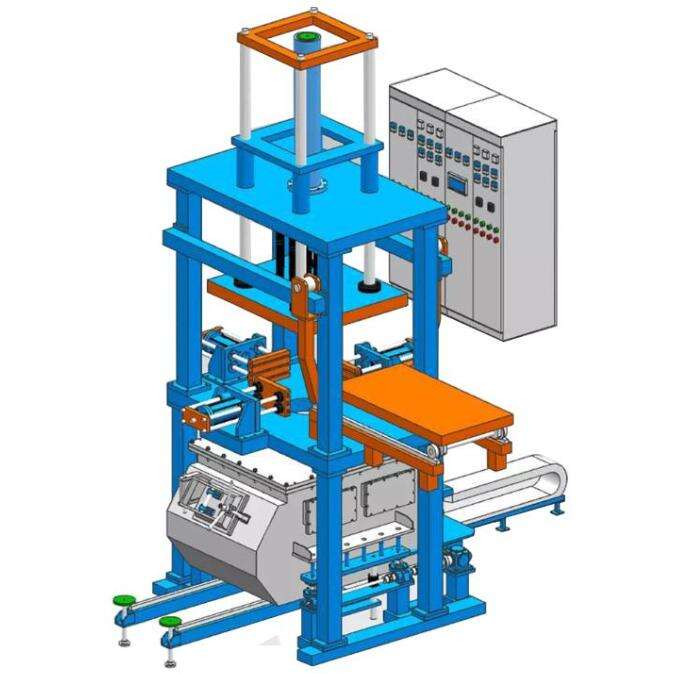

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include technical advice, equipment selection and manufacturing and process design, as well as training and operations. We are confident that our products will create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, Mold sand casting and other professional castings production enterprises.

In 1979 we started our journey in the field of Mold sand casting through the purchase of casting materials This was the start of our knowledge and presence in the marketplace Through the years we've built long-lasting relationships with our clients by providing high-quality products and exceptional service In 1997 we expanded our business to include manufacturing of industrial electric furnaces This strategic move allowed us to provide more comprehensive solutions for our clients and satisfy their increasing demand for dependable efficient heating equipment Our commitment to innovation and high-quality during this time period stood us out in the competitive landscape By 2002 we diversified our product offering by moving into the manufacturing of casting equipment sector This expanded our capabilities to provide a complete selection of casting solutions from materials to machinery to ensure that our clients could trust us with all their casting needs Our experience and extensive knowledge of the field have earned us the reputation of a reliable supplier for companies seeking top-quality casting equipment and services We've always been committed to customer satisfaction and continuous improvement This has enabled us to evolve and adapt in a market that is constantly changing

Our company has sold and made over Mold sand casting units since 1999. Excellent service and reliable quality make our company have a good reputation with its customers. The company has sold its products to Southeast Asia and Africa South America as well as the Middle East. Customers have also been satisfied with the service and quality. Customers should be encouraged to create more value.

The BoQiao gravity casting machine is Mold sand casting with a small structure and is a perfect choice for various production environments. Its high-performance makes for accurate and efficient casting and the user-friendly design makes the production process, allowing operators to attain the highest quality outcomes with only minimal training. This multi-purpose machine is used in a variety of sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it an investment worth making for companies looking for reliable casting solutions. It is praised by customers for its dependable quality, easy operation and maintenance and increased production.