×

×

Najdôležitejšie časti ventilového produktu sú odlitkové telesá ventilov. Každé z nich je dôležité na regulovaní pohybu kapalín alebo plynov cez potrubia. Predstavte si teleso ventila ako vonkajšiu časť, podobne ako kôžku jablká, ktorá obaly a chráni to, čo tvorí časť ovocia. Tu sa pozrieme na niektoré aspekty odlitkových teles ventilov. V tomto článku predstavíme Boqiao odlitkové teleso ventila z hľadiska toho, aké sú jeho hlavné komponenty vhodné pre vysokotlaké situácie s tradičnými širokými aplikáciami, ako sa formuje počas krokov odlievaných procesov, ktoré materiály sú kandidátmi na výber a hlavné faktory úvah pri vývoji výrobného dizajnu.

Telo ventilu sa skladá z niekoľkých hlavných častí, ktoré spolu pracujú. Patrí medzi ne, ale nie sú na nich obmedzené: horná flanga, dolná flanga, tela a štvrť. Ventil je pripojený k potrubiu cez jeho hornú flangu. Je to most medzi ventilom a potrubím. Ventil je pripojený k výstupnému otvoru potrubia cez svoju dolnú flangu, ktorá riadi výstup pre tekutiny alebo plyny. Telo – To je veľká časť vášho ventilového odlitku, v ktorej sú všetky ostatné vnútorné časti pevne udržiavané. Inými slovami, štvrť je to, čo otvára a zatvára prispôsobenie vášho ventilu. Otváranie alebo zatváranie štvrte, podľa toho, či otáčate páčkou alebo knopkom – obvykle je hlavnou metódou na umožnenie priepusti v prípade tekutiny/plynu, aby sa zastavila (zatvoriť), ak nie je požadovaná, takto funguje ako zátka vo vnútri softveru ventilu.

Tliepové trupky sú najlepšou voľbou pre situácie s vysokým tlakom, dokážu vydržať veľké záťaže a tlak. Ukázalo sa, že nemajú problém fungovať aj v najintenzívnejších podmienkach a neprasknú ani neutečia. Tieto sú vyrobené špeciálne tak, aby mohli vydržať aj vysoký rozsah tlaku. Navyše, Boqiao trupok ventilu je vyrobený z materiálov, ktoré trvajú dlhšie. A to ich robí dokonalými pre aplikácie, kde je potrebná takáto odolnosť, napríklad tam, kde je ventil obvykle pod stálym tlakom ako v továrňach alebo elektrárňach. Inžinieri ich používajú kvôli ich spoľahlivosti, kedy ju potrebujú aj pre dlhodobú udržateľnosť, čo je dôležité pre bezpečnosť a efektívnosť v týchto prostrediah.

Litie teles ventilov je zaujímavý proces, ktorý zahŕňa niekoľko kľúčových krokov. Prvou vecou, ktorá sa robí s formou, je, že do nej sa lije horký tekutý kov, čo nazývame tvar. Táto forma slúži na výrobu medzikrokového stavu pre telo ventilu. Do forme sa lije tekutý kov a potom dostane čas na ochlodenie. Po ochladení prejde z líquidného stavu do pevného podobného tvaru, ale viac prísne: takže sa tvaruje tela ventilu. Ďalším kľúčovým bodom o AM výrobných procesoch je, že ponúkajú spôsob, ako vyvíjať komplexné tvary, ktoré tradične boli ťažké alebo nemožné inými existujúcimi metodami. To spraví telo ventilu silným a trvanlivým kusom, ktorý vydrží vysoký tlak účinne.

Správny výber materiálu pre tela vávky je kritickým krokom. Výber materiálu bude priamo ovplyvňovať funkčnosť a životnosť tela vávky. Možnosti sú rôzne a každá z nich má určité výhody! Nerez, bronz, mosor a litnica sú niektoré z bežných voľb. Zásobníky z nerezu sú pre väčšinu spotrebiteľov prvou špecifickou voľbou, pretože sú neobyčajne pevné a odolné voči rezivosti, tento materiál je ideálny pre mnoho bežných použití. Ďalšie vhodné materiály na lisovanie sú bronz a mosor, často druhé najlacnejšie (ak by cena bola faktorom) po aluminíni; široko sa uvádzajú ako „nehodnotné“ na studené lisovanie. Na odkaz litnica má významnú pevnosť a je odolná skoro všetkým formám tepla, čo robí z nej voľbu pre strojárstvo.

Návrhy lisovaných trupov kranov by mali byť vytvorené tak, aby splnili úspech každej aplikácie. Musia byť vyrobené z správneho materiálu, výrobnou metódou, ktorá sa hodí k vašemu procesu a čo s nimi bude robiť za takého druhu tlaku atď. Presná znalosť toho, načo sa bude používať Boqiao lisovaný trup kranu a aký tlak musí vydržať, vám môže pomôcť pri výbere materiálu na výrobu kranov. Však samotný kran musí byť navrhnutý s ohľadom na určitý účel. Štvrté, voľba najlepšieho výrobného procesu je zárukou, že výroba lisovaných trupov kranov má dobrú kvalitu a splňuje všetky požadované normy.

Od roku 1999 sme vyrobili a predali viac ako 2000 kusov. Liatne telesá ventilov získali medzi zákazníkmi dobrú povest vďaka našej spoľahlivosti a kvalite, ako aj vynikajšej službe pre zákazníkov. Okrem predaja vo všetkých mestách po celej krajine sa naše výrobky tiež dodávajú do juhovýchodnej Ázie, Afriky, Južnej Ameriky, Blízkeho východu a mnohých iných lokalít a u zákazníkov sa veľmi osvedčujú. Na základe obchodnej filozofie spolupráce a vzájomného prospechu, upravenosti a integrity bude spoločnosť BoQiao pokračovať v odbornom rozvoji a neustále zlepšovať výrobky a služby tak, aby lepšie vyhovovali potrebám zákazníkov. Potrebujeme pomôcť zákazníkom vytvoriť väčšiu hodnotu.

V roku 1979 sme začali svoju cestu v oblasti odliatie telies ventilov prostredníctvom nákupu odlievalnych materiálov. Bol to začiatok našich znalostí a prítomnosti na trhu. V priebehu rokov sme si vďaka poskytovaným vysokokvalitným produktom a vynikajúcej obsluhe vybudovali dlhodobé vzťahy s klientmi. V roku 1997 sme rozšírili svoju činnosť aj na výrobu priemyselných elektrických pecí. Tento strategický krok nám umožnil ponúkať komplexnejšie riešenia pre našich klientov a spĺňať ich rastúcu poptávku po spoľahlivom a efektívnom vykurovacom zariadení. Naša angažovanosť voči inováciám a vysokokvalitnej produkcií nás v tom čase odlišovala na konkurenčnom trhu. Do roku 2002 sme diverzifikovali našu ponuku výrobkov tým, že sme vstúpili do odvetvia výroby odlievalneho zariadenia. Toto rozšírenie nám umožnilo ponúkať komplexný sortiment odlievalnych riešení – od materiálov až po stroje – a zabezpečiť tak, že naši klienti môžu dôverovať nám pri všetkých svojich odlievalnych potrebách. Naše skúsenosti a rozsiahle odborné znalosti v tejto oblasti nám vyslúžili povzbudenie spoľahlivého dodávateľa pre spoločnosti hľadajúce najkvalitnejšie odlievalne zariadenia a služby. Vždy sme boli oddaní uspokojeniu zákazníkov a neustálemu zlepšovaniu. To nám umožnilo vyvíjať sa a prispôsobovať sa trhu, ktorý sa neustále mení.

Nanjing BoQiao Machinery Co., Ltd je profesionálny výrobca zameraný na návrh, výrobu a predaj rôznych strojov na liatie, zariadení na tepelné spracovanie a priemyselných pecí. Medzi súčasne ponúkané produkty patria liatiny pod gravitáciou, liatiny pod nízkym tlakom, taviacie pece, žíhacie pece, kalenie pece, pece na starnutie a pece s priečnym magnetickým poľom, ktoré spolu tvoria 18 typov a takmer 100 druhov výrobkových špecifikácií. Ponúkame širokú škálu liatych tvarov kohútov, vrátane technickej poradenskej činnosti, výberu a výroby zariadení, návrhu technologických procesov, ako aj školení a prevádzkových služieb. Naše výrobky pridávajú hodnotu našim klientom. Produkty sa široko využívajú v nasledujúcich odvetviach: elektrické spojky, motocyklové súčiastky, autové súčiastky, nové energie, elektronika a elektrotechnika, vysokonapäťové prepínače, stavebná technika, liatiny pre letecký a vesmírny priemysel, ventilátory, spotrebná elektronika a iné odborné podniky vyrábajúce liatiny.

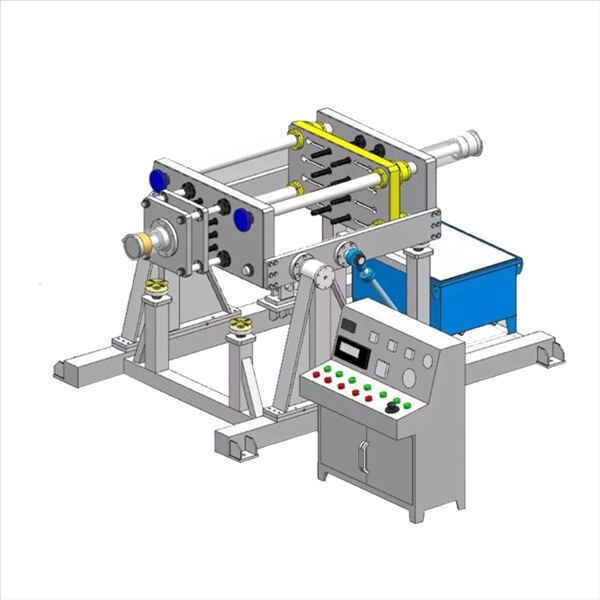

Liatička BoQiao s gravitačným liatím bola navrhnutá s kompaktnou konštrukciou, čo ju robí vhodnou na liatie kovových telies uzáverov v rôznych výrobných prostrediach. Jej vynikajúci výkon zaručuje efektívne a presné liatie, pričom priateľské pre používateľa ovládanie zjednodušuje výrobný proces a umožňuje obsluhe dosiahnuť optimálne výsledky po minimálnom školení. Táto všestranná strojová jednotka sa intenzívne využíva v mnohých odvetviach, vrátane výroby dielov pre motocykle, automobilové diely, elektrické rozvody a technické vybavenie. Nákladová efektívnosť a trvanlivosť stroja ho robia vynikajúcou voľbou pre spoločnosti hľadajúce spoľahlivé riešenia v oblasti liatia. Zákazníci ocenia stále vysokú kvalitu stroja a jednoduchosť jeho údržby a prevádzky, čo minimalizuje výpadky a zvyšuje produktivitu.