×

×

Die cast molds are a type of special tolls that have significant impact on multiple industries. Boqiao Aluminum casting parts manufacture metal pieces that are critical components in many consumer products. Fad Ostum, using a die cast mold commonly used in Chinese factories -- Of course whether the iPhone will stop being made here depends upon how big Apple's market share continues to grow. The goal here at Boqiao is to continue producing high-quality die cast molds that are utilized in millions of different products people use every single day, guaranteeing all of our customers receive the very best

Aluminum and steel are two of the most used materials for die cast molds. There are several important steps involved in making these molds. Before considering design of a mold Design: A successful mold follows a good design. The pattern, or prototype, is then sent to create a model for how the mold will function. After the test and everything is in place, they will make Isn't this miracle sinkers. It is the process of inscribing a design into metal. Then the metal is hardened to give a hard mold that can be reused over and again without any breaks or wear.

Prototype: After the design is done, a prototype (a mold sample)… This is very important because it tests the mold if it will work as design. Prototyping gives you a chance to mitigate risk by allowing on test the prototype before making the final mold, saving time and materials

Fabricate the Mold — After passing prototype testing, fabrication of the mold is next. A block of metal has the design cut into it, after which the metal is fired. In addition, Boqiao BQ quenching furnace hardening process is crucial because it results in a robust and well made mold that can easily handle the pressures associated with multiple reuses.

Finding a suitable die cast mold for your project is much like locking in the perfect setting solution. Molds come in many different types, some have benefits that others don't. There are some molds that work well for fabricating small parts and other that have been developed to accommodate larger features. Here at Boqiao BQ melting furnace, we have a team that is ready to assist you in choosing the appropriate mould for your specific requirements. We want to make sure you get the best mold for YOUR project in order to maximize your results.

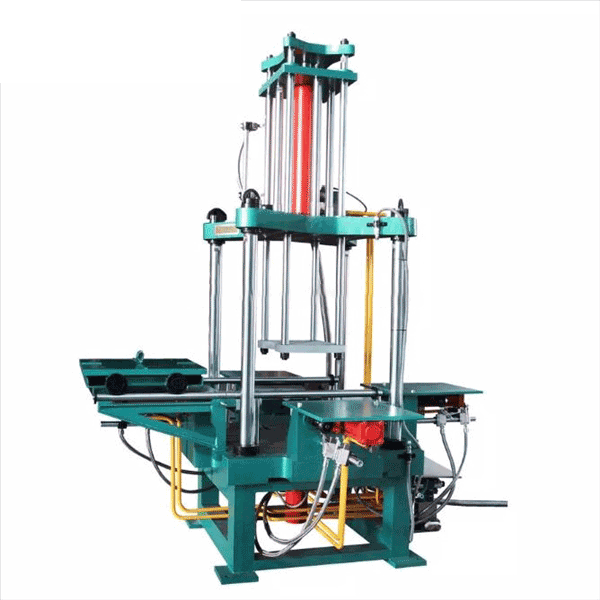

Vacuum Molds: ideal for larger piece parts This makes them an excellent choice for molds used to produce parts with complex geometry that is not easily replicated using other mold materials. Gravity die casting machines are also able to vacuum large shapes and finish the parts smoothly.

It is important you properly maintain your die cast molds if they are to last and produce great quality part for years. Cleaning and maintenance on a regular basis are crucial. These practices are done to prevent the mold from getting damaged so that it can continue working effectively for a longer period. Low Pressure die cast machines offers maintenance services for your molds We are here to help you maintain your molds for years more of great use.

Since 1999 the company has produced and sold more than 2, 000 units. BoQiao has Die cast mold a good reputation with customers because of our reliable quality and excellent customer service. Apart from sales in all cities and provinces across the nation Our products have also been sold to Southeast Asia, Africa South America, Middle East and many other locations, and have been a great success by customers. Based on the business ethos of cooperation and win-win, integrity and honesty, BoQiao will continue to follow the path of professional growth and continually improve its products and services to better meet the demands of customers. Customers must be helped to create more value.

Die cast mold journey into the field of casting began in 1979 with selling of casting material that laid the groundwork to our industry expertise as well as our market position. We've established lasting relationships with clients over the years by offering high-quality products, and providing exceptional service. In 1997, we grew to include the manufacturing of industrial electric heaters. This was a smart move that enabled us to offer more comprehensive solutions for our clients and satisfy their increasing demand for efficient, reliable heating equipment. Our determination to provide quality and innovation set us apart from the crowd. In 2002, we'd diversified our offerings by introducing the production of casting equipment. This expansion allowed us to provide a comprehensive array of casting options, from equipment to materials, ensuring that our clients can rely on us for everything they require in casting. We have earned the reputation of a reliable business partner because of our extensive experience and knowledge in the casting industry. Throughout our history, we have remained dedicated to constant improvement and customer satisfaction, which drives us to grow and change to a changing marketplace.

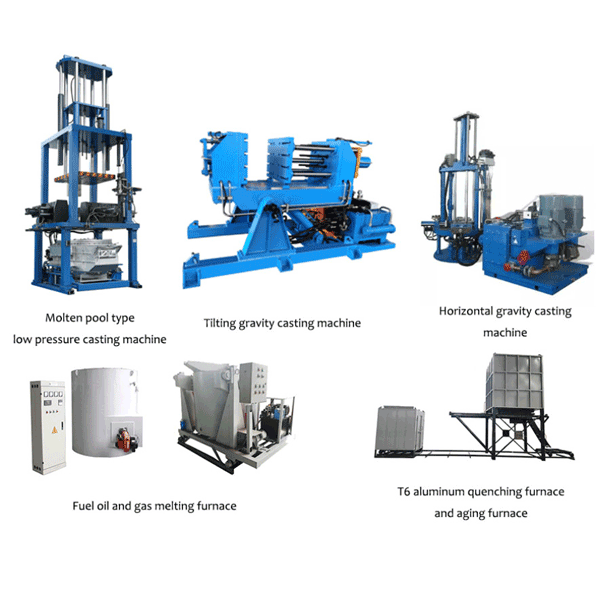

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include technical advice, equipment selection and manufacturing and process design, as well as training and operations. We are confident that our products will create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, Die cast mold and other professional castings production enterprises.

BoQiao's gravity-casting machine Die cast mold small dimensions, which makes it a good choice for many manufacturing settings. The BoQiao gravity cast machine's compact design and top-quality performance make it an ideal option for a variety of manufacturing settings. Its low cost and long-lasting capabilities make it an excellent investment for companies looking for solid casting solutions. The machine is highly regarded by its customers due to its constant high-quality, simple operation and maintenance and increased efficiency.