×

×

A foundry, a unique place where we melt metal and poured into the shape that is desired for us to form The things you have to do should be considered with great precision, and it is very far from giving the results. To get successful results in the projects you made with foundry, follow these correct steps and procedures. Some handy secrets which are all you need to churn out fantastic stuff every time you get down on that project of yours here.

After all, the beginning of a good result in your foundry will be choosing appropriate material. Because various metals have different melting points, you will need to choose the correct kind of metal that works well for your project. It is also important that the material should be clean, pure and of good quality. It may lead to problems and defects in the final output you can create, if your materials have impurities. Take the time to always see what quality, craftsmanship you are playing with Boqiao BQ melting furnace.

Additionally, it should be monitored once the melting has commenced as well. If the heat is not maintained then you may end up leaving dirt or any impurity in metal and your product will get waste. When you pour your metal into the mold be very careful not to spill any on yourself as molten lead will cause burns that are hard to treat without a professional. Everything needs to be closely monitored and this will help in gaining the maximum possible results, use Boqiao BQ quenching furnace.

For this reason it pays to be a good Foundry worker as well, because like any other skill, it definitely requires practice. Practice like any other skill works, only the practice makes you perfect. Start small and scale up to larger, more complicated projects. The idea is that you to learn new abilities and tools which eventually will be vital for achieving the best results with Boqiao Products.

A level of safety and fastidiousness is crucial to foundry work. There is just so much you have to check: the materials, mold and how or what temperature you melt to pour your metal. While in most cases, you would see a list of what those levels are – taking the time to double-check will keep oversights at bay and ensure your final product is free from errors.

Safety is a top priority while working at Foundries. Be sure to wear gloves, goggles, and a mask at all times so that you do not get burned or splashed. The piece is put through a heating process before it will air dry, so in the meantime make sure your work area is well ventilated to avoid breathing any toxic fumes. Safety first Protecting yourself (and those around you) is vital.

Since Satisfactory foundry the company has produced and sold more than 2 000 units. Excellent service and reliable quality make our company enjoy a positive reputation with clients. In addition to selling in every city and province across the country The company's products have been shipped to Southeast Asia, Africa South America, Middle East and many other locations and have been a great success by customers. Based on the premise of win-win and cooperation, sincerity and honesty, BoQiao will continue to take the road of professional development and continuously improve products and services to better meet the demands of customers. Need to help customers create greater value.

In Satisfactory foundry, we began our journey in the field of cast iron through the selling of casting components. This was the beginning of our knowledge and presence on the market. Through the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service. In 1997, we widened our business to include manufacturing of industrial electric furnaces. This strategic move enabled us to provide more comprehensive solutions to our customers and meet their growing demand for reliable, efficient heating equipment. Our commitment to innovation as well as the highest quality in this period was a distinct feature from the rest of the competition landscape. By 2002, we further expanded our product range by joining the casting equipment manufacturing sector. This expanded our capabilities to provide a comprehensive array of casting options, from machinery to materials making sure that our customers could count on us for all their casting requirements. Our vast experience and comprehensive understanding of the industry have positioned us as a trusted company for companies looking for top-quality casting equipment and services. Through our long history, we have remained dedicated to continual improvement and customer satisfaction, which has driven us to adapt and grow to a changing marketplace.

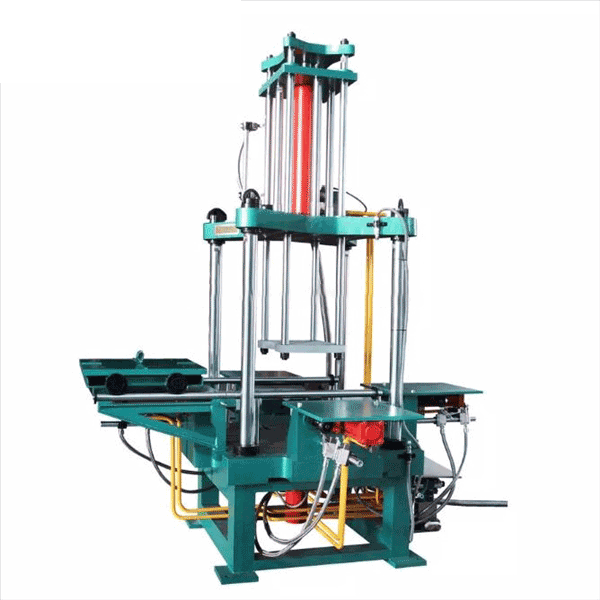

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly Satisfactory foundry of product specifications. We provide a variety of turnkey services, which includes technical assistance, equipment selection and manufacturing and process design, as well as training and operating. We can help our products bring value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

BoQiao's gravity-casting machine features an extremely compact design that is a perfect fit for many manufacturing settings. Its high-performance makes for the most precise and accurate casting and its user-friendly interface makes the production process, which allows users to get the best results with minimal training. This multi-purpose machine is utilized in many sectors, such as motorcycle parts automobile parts electrical power fittings as well as engineering equipment. Its long-lasting durability and low cost make it a valuable investment for businesses seeking reliable casting solutions. Customers appreciate the machine's constant quality as well as the ease of its operation and maintenance which decreases Satisfactory foundry as well as increases productivity.