Parts made of aluminum can warp or bend after being heated and cooled too quickly. That problem, known as distortion, renders the parts less useful or even unusable in machines. Boqiao has discovered ways to aid in this effort by employing a unique process known as controlled atmosphere sealed quenching. The process allows aluminum parts to cool more uniformly and gradually. It keeps the parts strong and in shape, when done properly. Most factories would like their aluminum parts to be perfect, but it is difficult. That’s why Boqiao tries so hard to get the cooling right, so the parts don’t warp or twist afterward.

A Methodolgy for Efficient Controlled Atmosphere Sealed Quench

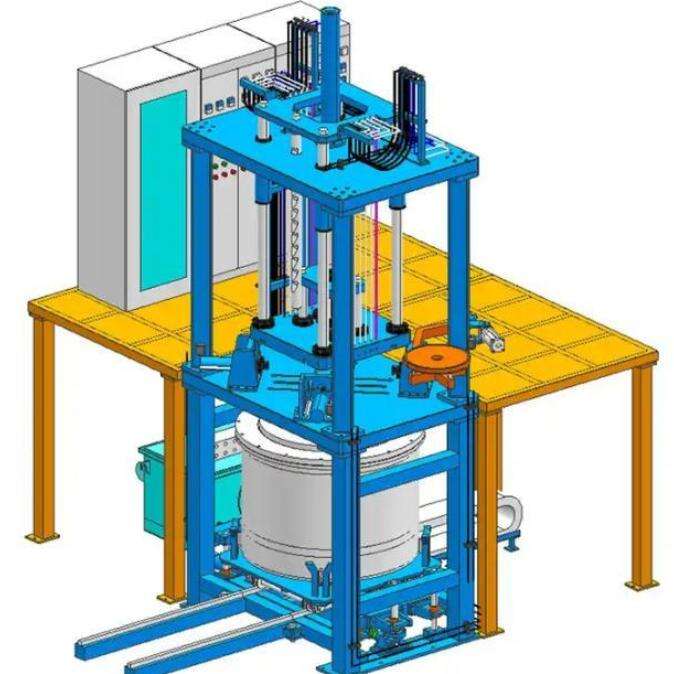

Here at Boqiao, we cool aluminum components via controlled atmosphere sealed quench furnace. What it means is the parts are placed in an enclosed area where the air or gas inside can be very controlled. This space protects against oxygen and moisture, which can damage or alter the surface of the metal. At times we'll flood the sealed chamber with specific gases nitrogen or argon, for example to shield the parts. The temperature in the chamber is also maintained, allowing the parts to cool slowly and uniformly. Cool aluminum too fast and one side might shrink faster than the other. This causes bending or warping. Our approach eliminates that possibility by ensuring that all parts cool at the same rate. We also are able to control the duration that the parts remain in the hot zone before cooling and that makes a world of difference. For instance, if the parts cool in minutes rather than hours, the likelihood of distortion is greater. But with Boqiao’s approach, the cooling time is regulated so that this doesn’t happen. We also are using sensors to monitor the temperature closely. This allows us to manipulate the speed of cooling right quickly enough. Another thought is to bag the pieces before they cool. That is because it prevents air from getting to the metal. We discovered through experience with multiple customers that every aluminum part requires a unique cooling strategy. Different shapes and sizes behave in different ways. OK, so our team tests and iterates until we get it right. This provides us with a cutting-edge advantage to produce increasingly strong parts that don’t lose shape. A lot of the time, what appeared to bend, was actually straight and strong after our controlled atmosphere sealed quenching process. “It just goes to show how important technique is. It’s not cooling fast or slow but cooling smart.

Controlled Atmosphere Sealed Quenching - How It Prolongs the Service Life of Aluminum Parts

This is what can occur when aluminum cools irregularly otherwise known as warping. One side cools more quickly and shrinks more, warping the metal. Boqiao’s controlled atmosphere sealed quench works to counter this by providing a calm and protective setting for cooling even and smooth. Think about what you are doing when you try to cool a piece of hot metal out in the wind. The wind will cool some areas more quickly than others. This causes bending and twisting. But if you put that same piece in a closed box, with air or gas of a uniform temperature all around it, the cooling is pretty much fair all over. Neither side gets too cold too quickly. The sealed environment also prevents reactions with oxygen, which can weaken the metal and produce rough surfaces. This helps the aluminum to stay strong and clean. Our process also eliminates the moisture that can lead to spots or corrosion after cooling. Pressure in the closed space is another consideration. By controlling the pressure, Boqiao can ensure that the aluminum does not crack or distort. As an example greater pressure in the presence of inert gas suppresses heat loss. This leaves the metal time to relax into its new form. We found that aluminum parts with thin walls or intricate shapes are the most likely to warp. So, our process controls the gas mix and temperature and pressure based on the design of the part. This controlled reduction in the risk of warping. Additionally, the enclosed system prevents particles of dirt and dust from clinging to parts as they cool. This maintains smoothness of the surface and prevents defects. I learned over the years working with aluminum parts that even small changes in cooling can make a big difference in shape. That is why Boqiao says he tries to be in control of every little thing, including both the writing and singing. It’s not magic, but it feels like it. When components are cooled down in our cleanly controlled sealed environment, they turn out the way they must be. Straight Strong and ready to use. That makes all the difference for customers who require consistent parts.

High-Quality Aluminum Parts with Little to No Distortion in Our Turnkey Wholesale Solutions

A big problem in making aluminum parts is keeping them the right shape. It is used in making many products because it is a light and strong metal. Yet, when aluminum parts are heated and then rapidly cooled, they can warp or bend. This change is known as distortion, and may render the parts less useful, or even destroy them. That’s why it is so critical to look for ways to minimize distortion. One great way to do that is by employing special techniques for cooling following heating of the aluminum parts. Boqiao provides wholesale service, the manufacturer buys high quality aluminum parts with very little distortion. They use what is known as controlled atmosphere sealed quenching. This is because the aluminum parts are cooled in a very sensitive environment, in which the air around them is controlled to ensure that the cooling occurs evenly and gently. This careful management helps the parts hold their valid shape. Through Boqiao, businesses can receive large quantities of aluminum parts that meet rigorous quality requirements. That saves money because there are less that break or need repaired. And parts also last longer and work better in machines or tools. Boqiao’s wholesale services also include advice and assistance to ensure quenching is properly performed. This way, factories minimize mistakes and achieve the best outcomes. So, if you need many strong, dependable aluminum components that won’t suffer distortion, Boqiao’s controlled atmosphere sealed quenching is the solution. They are a good blend of technology and careful control that make sure the aluminum parts remain in great condition from start to finish.

Where to Turn for Trusted Controlled Atmosphere Quenching Services of Aluminum Parts

To prevent aluminum from warping or distorting, it is really important to find a reputable business for controlled atmosphere quenching. This rarefied cooling process is exacting and you need expertise, as well as good equipment because the air and temperature have to be controlled with a high degree of fineness. Boqiao is a source for dependable controlled atmosphere sealed quenching of aluminum parts. They have the right machines, and they have experts that know how to cool aluminum parts without damaging them. When heated, aluminum parts soften, causing them to become fragile and susceptible to bending or twisting if they cool too quickly or unevenly. The process developed by Boqiao forms an enclosure around the parts and regulates both gases and temperature during cooling. This keeps the parts from oxygen or moisture, which can result in rusting or surface issues. With Boqiao you can rest assured that your aluminum parts are treated with care. The company also provides good communication and support, explaining the process to clients and what they should expect as a result. This streamlines working together and minimizes errors. Whether you are involved in automotive, aerospace or electronics, dependable quenching is critical to producing strong aluminum parts. With Boqiao’s proven track record of services and technology, the search for your right service is easy. So for those in need of controlled atmosphere quenching, Boqiao is definitely one company to look into. Their high-quality, distortion-free aluminum parts enable countless businesses to upgrade their products and remain at the forefront of their industries.

You probably also wonder how the controlled atmosphere sealed quenching system can enhance the life and performance of your products delivering savings.

Sealed quenching in a controlled atmosphere is not only for preventing aluminum parts from bending. It also makes the parts stronger and better at what they do. When aluminum is heated and cooled in the right way, its interior structure shifts morphed into a form more durable; equipped for better performance. It is necessary to control the cooling step of this quenching process carefully and Boqiao does this by their controlled atmospheric sealed quenching system. The cooling is even and doesn’t create the sorts of reactions that can be toxic. That strengthens the metal and eliminates cracks or weak spots. The result is long-lasting, durable aluminum parts that perform very well, even under demanding conditions. For instance, parts that go into cars or airplanes must be able to withstand stress and heat without breaking. It also allows these parts to remain strong and durable. Boqiao’s quenching method enables this. And the smooth surface finish from this process makes it fit better with other parts, while reducing wear and tear. That means machines and products can run more efficiently, require less repair. Controlled atmosphere sealed quenching also generates less waste as fewer parts are scrapped or have to be reworked. This is a cost saving and environmentally friendly approach, as less extra material is required. In general, Boqiao’s approach is enabling companies to make aluminum parts with that are stronger and longer lasting and higher performing. This in turn makes a product safer and better for users. Thanks to this state-of-the-art cooling procedure, aluminum parts can meet the most challenging requirements of modern technology and industry meaning high quality and value in each part.

Table of Contents

- A Methodolgy for Efficient Controlled Atmosphere Sealed Quench

- Controlled Atmosphere Sealed Quenching - How It Prolongs the Service Life of Aluminum Parts

- High-Quality Aluminum Parts with Little to No Distortion in Our Turnkey Wholesale Solutions

- Where to Turn for Trusted Controlled Atmosphere Quenching Services of Aluminum Parts

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY