×

×

An appliance that melts the material so it can be used to mold metal objects is a Boqiao casting furnace Metal casting: Making the metal form that we want to use in manufacturing is called as Metal casting. Firstly, the metal is placed in a crucible and then heated to its melting point. Once the metal is molten, it can be poured into a mold — an empty space which gives shape to that form of metal. The casting furnace plays a very important role in this whole process because here the metal is melted to just enough temperature making it possible for any desired patterns.

Metal casting is used heavily in factories to produce a wide array of products from tools, right through to car parts. The casting of a good BQ melting furnace is very important in this process because it ensures strength and quality metal production. They may not be strong enough if The furnace is of poor quality And this can prove to be an issue, either because the produced aspects might break down too easily or cease to operate sooner than they are supposed. Therefore, that makes it very important to use a good Boqiao casting furnace to ensure the metal is consistently durable and will be able used for several items.

You will find multiple types of Boqiao casting furnaces with various functions based on the production features used in factories. One example of this is how electric furnaces heat the metal with electricity. Gravity die casting machines is quick to manipulate and efficient, these are some of the good qualities carried by this furnace. Gas vs OilWhile gas and oil are equally strong fuels, they heat your system in different ways. When it comes to a furnace, the fuel decides how functionally well-maintained the thing is. With an oil-powered device like this heater you will find that the metal may be heated together with things growing even hotter when compared to their gaseous alternatives.

On another end of matters though those who go for something such as this could want some extra cooling down first having either propane or home heating essential which might just change certain aspects life due exceptionally excessive temperatures then again switching over every so often between what works very best overall herein lies question greatly debated within evolutionary cityscape by itself all geared toward finding fruit chamber chilly enough. Although they can melt a lot of metal, electric furnaces are not the fastest method and it may take some time.

The induction furnace is a type of another Furnace. These Boqiao casting furnace are the types which utilizes high potency magnets to generate heat so that it can burn metal with a flash. Induction furnaces are more efficient than others and have widespread applications in many industries. The ceramic shell of BQ quenching furnace are used for the most accurate and precise work These melting and cooling furnaces can keep a uniform temperature throughout the process, resulting in proper products that meets international quality standards.

At first, the Boqiao casting furnace process may seem complex but in isolation there are actually quite simple steps that make up virtually most of what you need. The first step is for metal to be loaded into the furnace where it will undergo melting. The furnace is then heated to the desired melting temperature of that type of metal. After the metal is fully molten and turned into liquid, it pours slowly onto a mold. Once Aluminum casting parts is poured, the mold sits by itself to cool. Once the metal cools off and moves into shape it can easily be removed from mold. In the end, all that remains is for them to finish and polish it so you can have a nice-smooth exterior without defects or anything else wrong with your repainted body kit.

Considerations to Make in an Casting Furnace When selecting a Boqiao casting furnace that is right for you, there are few things I should be kept into considerations. As a first step, think of the metal you are going to melt and how much load can be taken up by one container. Also, consider the output quality which you intend to have in end product. To consider —Each type of Products fuel (electricity or gas) and therefore the furnace must also be chosen to adapt to how much you will produce. You should use the service of a branded furnace making company. And Boqiao is one company providing broad category of casting furnaces corresponding to various industries and needs.

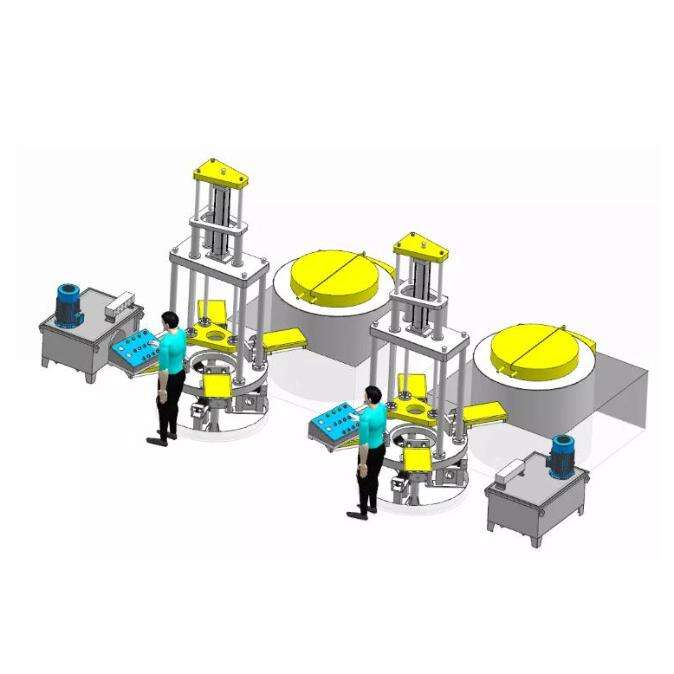

BoQiao's Gravity Casting Machine has a compact design, which makes it a good choice for many manufacturing settings. Its superior performance ensures efficient and precise casting, and its user-friendly interface makes the production process, allowing operators to achieve optimal results with little training. This multifaceted machine is widely used in a variety of industries, including motorcycle components auto parts, auto parts, Casting furnace, and engineering machinery. The durability and affordability make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by its customers due to its constant quality, ease of operating and maintenance, and the increased efficiency.

Our Casting furnace has sold and manufactured over 2, 000 units from 1999. Reliable quality and excellent service make our company enjoy a great reputation among customers. In addition to sales in every city and province across the country Our products have also been offered to Southeast Asia, Africa South America, Middle East and other regions, and have been a great success by customers. Based on the premise of win-win and cooperation, sincerity and honesty, BoQiao will continue to pursue the path of professional development and continuously improve products and services to better meet the demands of customers. The need to assist customers in creating more value.

Nanjing BoQiao Machinery Co., Ltd is a Casting furnace, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer our customers all kinds of overall solutions and turnkey projects, including technical consulting, equipment selection mold manufacturing design, process development, operating training, and more. Our products can create an added value for our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our journey into the casting industry started in 1979 with sales of casting materials creating a Casting furnace for our experience and market presence We have built lasting relations with our clients throughout time by providing high-end products as well as providing outstanding customer service In 1997 we began to include the manufacturing of industrial electric heaters This was a smart move that enabled us to offer a wider range of solutions to our clients addressing their growing demands for efficient and reliable heating equipment Our commitment to innovation and the highest quality in this period stood us out in the competitive landscape By 2002 we further broadened our offerings of products by joining the casting equipment manufacturing sector We could offer an array of options to casting encompassing materials and machines This enabled us to be a one-stop store for our customers with casting needs Our years of experience and profound knowledge of the industry has positioned us as a trusted partner for businesses seeking top-notch casting equipment and support In all our years we've always been dedicated to continuous improvement and client satisfaction which has driven us to change and evolve to the ever-changing marketplace