×

×

Did it ever occur to you how metal things, like chairs and cars are manufactured? It may all seem like magic, but in fact there is a very special machine that aids to smelt these brass stuffs. The name of this machine is automatic casting machine. A neat little gadget that brings metal items to life of any size and shape.

It used to take forever a lot of work by hand just fabbing/making metal pieces, same with the Boqiao Gravity die casting machines. Everything had to be made by hand, which took ages and considerable skill. They sat and twisted the metal for hours upon hours until finally, into form. But now with the help of this fantastic casting machine to make metal things is more simple and easy than it was at that time. This machine has literally revolutionized how we produce metal products.

An automatic casting machine as well as Low Pressure die cast machines helps in producing metal objects faster, easier and less time-consumingly. This is how it works: A mold, the shape that we want to give metal,(liquid and hot) pours liquid iron. Eventually, hot metal cools and solidifies into the shape of the object we desire. This process is known as casting, and it is used to create a plethora of many diverse things such as car parts, tools or gorgeous jewelry.

This Boqiao machine is great, one of the best that I have been able to test and check out — and its accuracy. It can output objects with very fine detail and complex shapes that would be a pain to make by hand. This is crucial as a lot of metal items need to look spotlessly perfect. The machine does it the same way every time, producing consistently reliable results. This ensures that all products manufactured with the machine will be identical, a crucial feature for businesses seeking to produce high numbers of one item.

This means that your company can produce many more products in a much shorter time. This helps to save them money and also allows for more items on sale, same with the BQ melting furnace. Faster plants make everyone feel better — from the workers to the bosses. And it also lets the workers do other things with their time instead of grinding away all day making metal objects.

If true it means companies can sell more stuff and make money as a result. It is also good for employees because it ensures that they will be able to retain their jobs and have opportunities to expand as the company grows and expands. A company prosperous can provide many more jobs to the workforce, thus benefiting all parties.

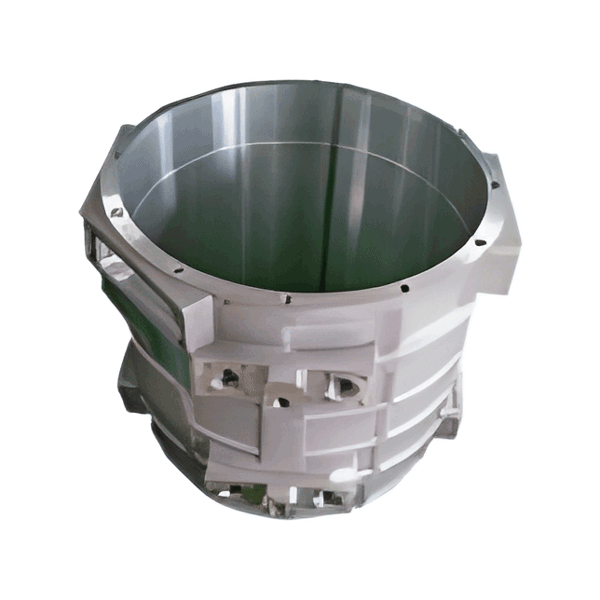

Structure of the Boqiao automatic casting machine also BQ quenching furnace is not ordinary Is one of the more sophisticated methods which employs cutting edge computer programming and engineering to generate strong, robust metal objects in a durable fashion. It is also designed to be efficient, capable of spotting issues during casting itself. If there are, it will determine those issues and can apply corrective actions immediately to guarantee the end results meet standard quality.

Automatic casting machine journey into the field of casting began in 1979 with selling of casting material that laid the groundwork to our industry expertise as well as our market position. We've established lasting relationships with clients over the years by offering high-quality products, and providing exceptional service. In 1997, we grew to include the manufacturing of industrial electric heaters. This was a smart move that enabled us to offer more comprehensive solutions for our clients and satisfy their increasing demand for efficient, reliable heating equipment. Our determination to provide quality and innovation set us apart from the crowd. In 2002, we'd diversified our offerings by introducing the production of casting equipment. This expansion allowed us to provide a comprehensive array of casting options, from equipment to materials, ensuring that our clients can rely on us for everything they require in casting. We have earned the reputation of a reliable business partner because of our extensive experience and knowledge in the casting industry. Throughout our history, we have remained dedicated to constant improvement and customer satisfaction, which drives us to grow and change to a changing marketplace.

Our firm has sold and manufactured over 2, 000 units in the last year. Automatic casting machine and reliability make our company have a good reputation with customers. Apart from sales in every city and province across the country Our products have also been shipped to Southeast Asia, Africa South America, Middle East and many other locations and have been a great success by customers. Based on the business ethos of cooperation and win-win, sincerity and honesty, BoQiao will continue to follow the path of professional growth and continuously improve products and services to meet the demands of customers. The need to assist customers in creating more value.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a wide range of Automatic casting machine that include technical consultation, equipment selection and manufacturing and process design, as well as training, and operation. Let our products add value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

BoQiao's gravity-casting machine Automatic casting machine small dimensions, which makes it a good choice for many manufacturing settings. The BoQiao gravity cast machine's compact design and top-quality performance make it an ideal option for a variety of manufacturing settings. Its low cost and long-lasting capabilities make it an excellent investment for companies looking for solid casting solutions. The machine is highly regarded by its customers due to its constant high-quality, simple operation and maintenance and increased efficiency.