×

×

Do you know that pump casting is essential to ensure the ease and efficiency of pumps, but do not have a clear understanding about it? This Boqiao text takes you through pump casting — What it is, and how it gears things up for the pumps in different industries. The more complexly we understand this process the better can appreciate the machinery that most of us take largely for granted.

Pump casting is a type of special process where pumps are created by pouring molten hot metal in to pattern, which looks like mold. This Gravity die casting machines is very important attribute to have in order for the pumps drawn are detailed and precise. Pump casting is one of the best ways to acquire with high performance pumps which are imperative for a variety of different industries worldwide, including and not limited to: oil and gas energy production, water treatment facilities as well as industrial settings.

Pump Casting is a nice way to manufacture pumps because it gives the option of having only special designs. This Boqiao makes it possible to create different pumps based on needs. They Low Pressure die cast machines can be engineered to handle specific water flow rates, pressure ratings and with the best materials for what their intended use requires. In many instances, this level of customization is the exact reason why pump casting can be so invaluable as well.

The basic pump casting process starts with a mold. There are many materials available for this mould, sand being an example of a common one. Choosing the right material for the mold is really important because if you choose wrong it could collapse during injecting. After the mold is prepared, it is heated to dry out any moisture and toughen up a bit before having hot liquid metal poured into it.

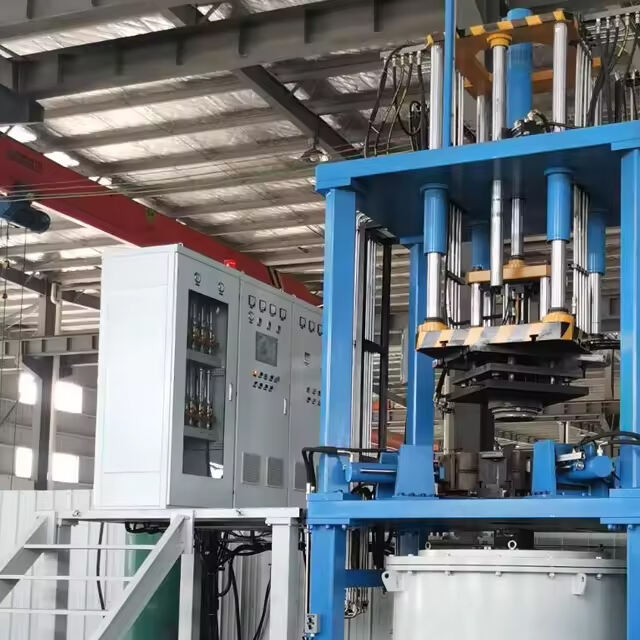

The mold is now prepared and the hot metal will be poured into it. The BQ melting furnace metal is allowed to cool and harden. The Boqiao mold is then carefully removed once the part has cooled entirely, and the excess material from weld-over pins will be cleaned up to shape it for specified dimensions. In other cases more features could be added to the final pump design such as fins or special internal structures.

The benefit of pump casting is, it provides the designs for making such pumps that results in enhancement its performance level to a great extent. The BQ quenching furnace simplest form of this product line would just be a variable capacity pump or perhaps more as you mentioned, pumps can still be made to custom fit any need such changing flow rate demands, head pressure requirements and energy consumption. Design freedom is thus essential in enabling the work pumps are needed to accomplish.

Also, pumps can be built to have long life or withstand damage, which is critical in industries where pumping conditions are difficult and harsh enough (eg high temperature media; aggressive constituents). The Aluminum casting parts long run of your pumps working more effectively is due to the fact that they are capable of customizing them for durability.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Pump casting customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

BoQiao's Gravity Casting Machine has a compact design, which makes it a good choice for many manufacturing settings. Its superior performance ensures efficient and precise casting, and its user-friendly interface makes the production process, allowing operators to achieve optimal results with little training. This multifaceted machine is widely used in a variety of industries, including motorcycle components auto parts, auto parts, Pump casting, and engineering machinery. The durability and affordability make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by its customers due to its constant quality, ease of operating and maintenance, and the increased efficiency.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a wide range of Pump casting that include technical consultation, equipment selection and manufacturing and process design, as well as training, and operation. Let our products add value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

Our journey in the field of casting started in 1979 with sale of casting materials and laying the foundation to our industry expertise and market presence Over the years we've established long-lasting relationships with our clients by offering high-quality products and excellent service In 1997 we widened our operations to include the manufacturing of industrial electric furnaces This strategic move allowed us to provide more complete solutions to our customers meeting their growing demands for efficient and reliable heating equipment Our dedication to innovation and quality during this time made us stand out from the rest of the competition landscape By 2002 we expanded our product range by moving into the manufacturing of casting equipment sector This expanded our capabilities to offer a wide range of casting solutions from materials to machinery making sure that our customers could count on us for every aspect of casting We're a trusted business partner due to our extensive experience and knowledge in the Pump casting Since our beginning we have remained dedicated to continuous improvement and customer satisfaction which has driven us to evolve and adapt in an ever-changing market