×

×

Ever heard of cast components? These are some really important parts that you can find in a lot of things we use every day. Cars, Face Masks and an Impressive Toy. These things can be found in many cars, even some of your favourite toys. What are Cast Components?, How are they made? and How is it important?

Cast parts are made by pouring liquid metal into a mold. The die is a unique vessel for our blank, as it molds the metal into the desired part. Depending on the molding material, molds can be made from sand or a type of ceramic. Once metal has been poured, it cools and solidifies. When the metal cools and solidifies, the mold is removed leaving complete part component which can be put to use in machines or any devices. The process of creating parts in Boqiao Gravity die casting machines like this is typically referred to as casting, and it's critical to producing a wide variety of products.

Cast parts are some of the best in strength out there, and they can serve you a good amount of time. That also means they can go through a lot of use, wear and tear without getting broken too easily. Cast components. Castings are idea for the parts that need to strength and durability. Boqiao BQ melting furnace can also be manufactured in numerous shapes and sizes, which makes them incredibly versatile across several machines and devices. This includes gears, brackets and engine components for cars or planes.

Production of cast components. The production of a die casting part is practiced by melting metal to be applied to the work. This metal is heated slightly, until it reaches its molten form. The hot metal is then poured into a carefully designed mold to solidify it with the shape of part that you want. The metal is poured inside the mold and allowed to cool down thereby resulting in a hardened shape. The duration of this cool-down cycle can vary from only a few hours to several days if the parts are large and complex.

Cast components are used in many different modern machines and devices. Cars and Planes are just the beginning, medical machines use them too along with some toys. This strength and longevity have a wide range of uses. Boqiao Aluminum casting parts are easy to manufacture on a large scale, which is rather useful when it comes to producing such items as automotive and household goods. The capability to manufacture large quantities of parts helps reduce costs, while also providing a cost-effective solution for replacing any damaged or worn components.

Auto mobiles: Cast components production is very important in auto sector and primary parts of car are produced according to process cast. These things made from engine blocks Low Pressure die cast machines, transmission housing and brake calipers.

Medical: For the medical industry, the need is for strong and robust parts. Examples of such things are prosthetic limbs, surgical instruments and indeed the component parts for various medical devices. And cast components make a large portion of them. These parts of BQ quenching furnace have both high load capability and are reliable which can greatly affect patient care.

Since 1999, our company has Cast components and sold over 2000 units. Our company has a stellar reputation among its customers due to our reliability and quality as well as excellent customer service. In addition to selling in all cities and provinces across the nation Our products have also been offered to Southeast Asia, Africa South America, Middle East and many other locations, and have been a great success by customers. Based on the business model of win-win and cooperation, honesty and sincerity, BoQiao will continue to pursue the path of professional development and constantly improve products and services to meet the development of customers. It is essential to help customers create more value.

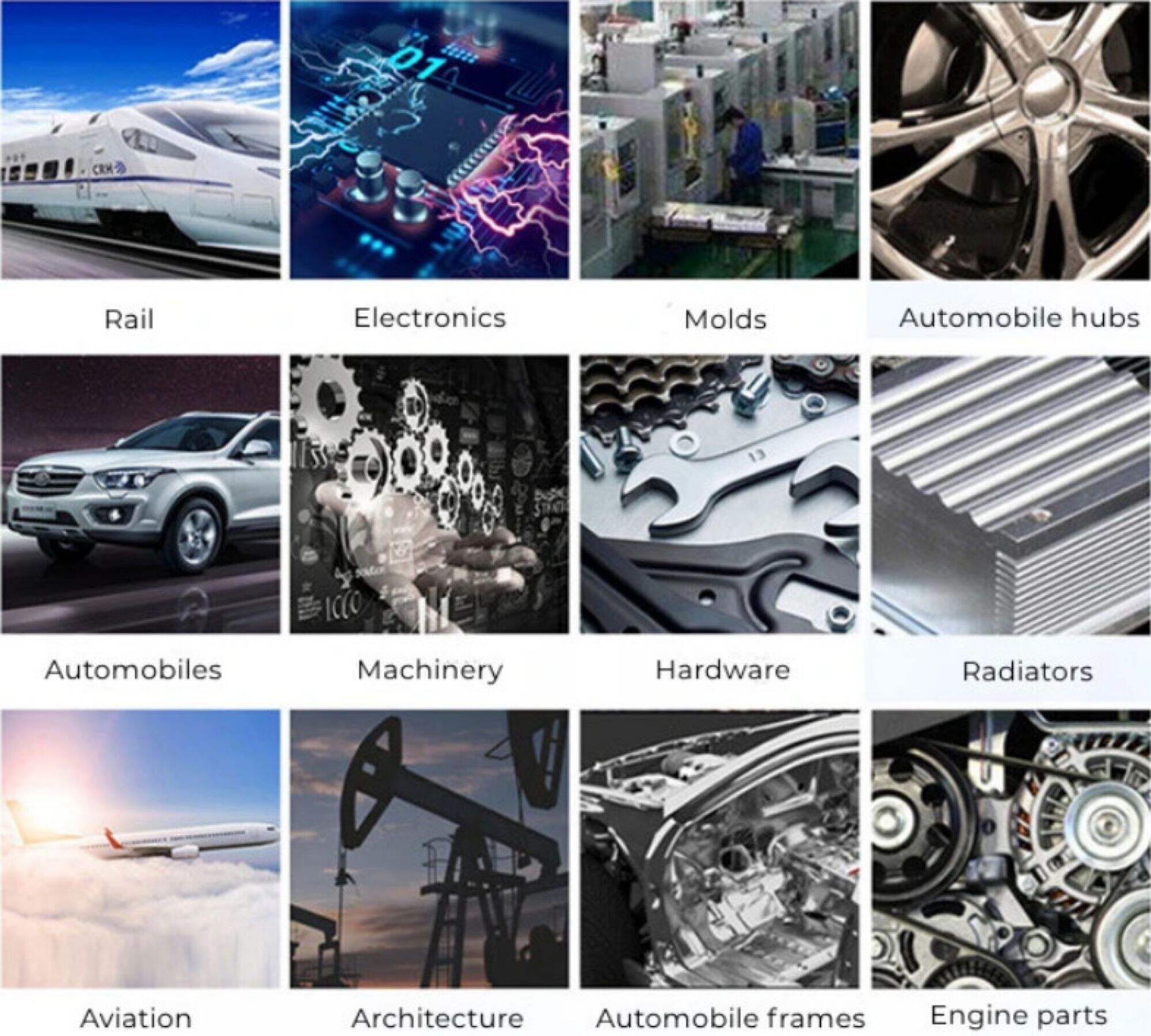

Nanjing BoQiao Machinery Co., Ltd is a Cast components, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer our customers all kinds of overall solutions and turnkey projects, including technical consulting, equipment selection mold manufacturing design, process development, operating training, and more. Our products can create an added value for our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

BoQiao's gravity cast machine is a compact design, which makes it a good choice for a range of manufacturing settings. The Cast components of the machine ensures accurate and efficient casting while its user-friendly system simplifies the production process, which allows users to get the best outcomes with only minimal training. This multi-purpose machine is used in a variety of industries, such as motorcycle parts automobile parts and electric power fittings as well as engineering equipment. The durability and affordability are a great investment for businesses seeking solid casting solutions. The machine is highly regarded by customers for its consistent high-quality, simple operating and maintenance, and the increased production.

In 1979 we started our journey in the industry of cast iron with the purchase of casting materials This was the beginning of our experience and our presence on the market We've established lasting relationships with our clients over the years offering top-quality products and offering exceptional customer service In 1997 we expanded to include the manufacturing of industrial electric heaters This move was a strategic one that allowed us to provide more complete solutions to our clients addressing their growing demands for efficient and reliable heating equipment Our determination to provide quality and innovation distinguished us from the competition By 2002 we'd further diversified our offerings by introducing the production of casting machines This expansion allowed us to offer a wide array of casting options from materials to machinery and ensure that our customers could rely on us for all their casting needs Our vast experience and comprehensive understanding of the industry have established us as a trusted company for companies looking for top-quality casting equipment and support Since our beginning we've remained committed to continuous improvement and client satisfaction which drives us to change and evolve to the ever-changing Cast components