×

×

We will never had to wonder how toys, bottles or even car parts are manufactured. Injection moulding machines are some cool slices of equipment, and you know what, those products above that I have mentionedB (it may shock you) can be made off these too. This Boqiao Low Pressure die cast machines is fantastic for us as it enables to create many of the same product at once. At Boqiao, we use these machines to create products that our customers love and desperately need.

Now, how does injection moulding work? It all starts with really small pellets of plastic. When melted, this little pieces of plastic. Once melted, the soft plastic is pushed into a mould. The mould is thereby like a special container having the exact form, we intend as shape of final product. After the plastic in melted then place it inside of a mold, it cools down. As the molten plastic is cooled, it solidifies and assumes the shape of the mould. Once the plastic is cured, the mould opens and out pops your new product. Kitahara now has a killer rig to work on his cabin, and it seems kind of magical how well everything lines up.

We need the injection moulding machines as they are a critical element to making our products in the way we do industy-less quantities. They used to make every product by hand in the old days which was not only very slow but sometimes also way too inaccurate. That would take forever if they had to do every toy one-by-one! However, now with the help of injection moulding machines hundreds or even thousands of products can be produced in a very short period. That's why we are able to get products out the door in record time, and everyone is happy about that. Additionally, Boqiao Gravity die casting machines keeps prices a bit lower for everyone and allows more people to enjoy the games we produce.

In all aspects of life we see continual improvement, and injection moulding machines are no exception. Here at Boqiao, we are always looking for better and more efficient ways to enhance our product offerings. One of the ways we achieve this, is through utilizing computers to aid in controlling these machines. The machines function with much greater accuracy than when we use computers, which allows them to produce even more similar products. This is very important as it helps us to make sure everything we ship meets our high quality bar. We notably never use non-recyclable materials and also be careful to utilize resources that can be reprocessed as soon as it is our turn. This allows us to spare benefit and be gentle on the planet by saving nature.

They are literally the Best When it comes to manufacturing a lof of products very quickly and accurately, there is nothing better than Injection moulding machines. The Boqiao BQ quenching furnace can produce a product in many different shapes and sizes. It can also produce variety of materials including metal, plastic and even rubber! We have a long history using these machines at Boqiao for quality products you can rely on. We love what we do and hopefully you now have a little bit of an understanding on injection moulding machines, why they are important in our business to provide high quality products to everyone.

Injection moulding machinery journey into the field of casting began in 1979 with selling of casting material that laid the groundwork to our industry expertise as well as our market position. We've established lasting relationships with clients over the years by offering high-quality products, and providing exceptional service. In 1997, we grew to include the manufacturing of industrial electric heaters. This was a smart move that enabled us to offer more comprehensive solutions for our clients and satisfy their increasing demand for efficient, reliable heating equipment. Our determination to provide quality and innovation set us apart from the crowd. In 2002, we'd diversified our offerings by introducing the production of casting equipment. This expansion allowed us to provide a comprehensive array of casting options, from equipment to materials, ensuring that our clients can rely on us for everything they require in casting. We have earned the reputation of a reliable business partner because of our extensive experience and knowledge in the casting industry. Throughout our history, we have remained dedicated to constant improvement and customer satisfaction, which drives us to grow and change to a changing marketplace.

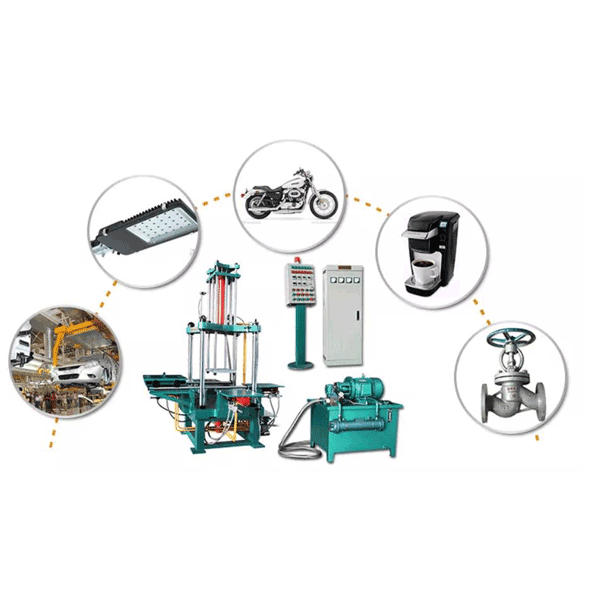

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include technical advice, equipment selection and manufacturing and process design, as well as training and operations. We are confident that our products will create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, Injection moulding machinery and other professional castings production enterprises.

Our company has sold and made over Injection moulding machinery units since 1999. Excellent service and reliable quality make our company have a good reputation with its customers. The company has sold its products to Southeast Asia and Africa South America as well as the Middle East. Customers have also been satisfied with the service and quality. Customers should be encouraged to create more value.

BoQiao's gravity-casting machine features an extremely compact design that is a perfect fit for many manufacturing settings. Its high-performance makes for the most precise and accurate casting and its user-friendly interface makes the production process, which allows users to get the best results with minimal training. This multi-purpose machine is utilized in many sectors, such as motorcycle parts automobile parts electrical power fittings as well as engineering equipment. Its long-lasting durability and low cost make it a valuable investment for businesses seeking reliable casting solutions. Customers appreciate the machine's constant quality as well as the ease of its operation and maintenance which decreases Injection moulding machinery as well as increases productivity.

With Injection Moulding Machines, every part had to be the exact same size and shape! This becomes even more vital when things must align properly, like a cars tail lights or multiple toy components. It is often the case that these parts are quite hard to make in a repeatable way without using machinery. With that being said, of course every part up fits and functions perfectly because they have the technology to make parts exactly identical.

Conservation of materials in injection moulding machines However, even when it comes to items made by people there is always going to be some waste left over from the materials used. However, with machines the amount required for each component can be adjusted specifically as well. The result of this, BQ melting furnace will not only assist in our green efforts but less stuff is going into the waste and therefore waste materials are being used with a purpose.

The machines are also really good at working new stuff out much quicker than you can knock up a dozen by hand. This is important for businesses that need to manufacture many parts in order to make a profit. This can also help businesses achieve their production targets easily by using these machines.