×

×

Did you ever wonder on how we manufacture mechanical parts? It’s a fascinating process. Casting is one of the primary methods that we use to make these components. It is in the form of casting which is when a liquid material (like metal or plastic) are poured into particular forms, molds. After the liquid forms into the mold, you allow it to cool and stiffen up-guidelines supplied by wax service provider. As soon as it cools down, we remove the casting from chassis and this is our part! In this way we can create countless mechanical parts from small gears to valves even engine component which make cars or machines work.

The Most Basic Things Are the Various Methods of Casting When you are casting mechanical parts, one thing that everyone must know about is the different methods in which you could caste a particular part. Types of Casting: There are many types of casting and some important ones include · Sand Casting · Investment casting · Die-casting All the three methods have their own pros and cons. An example of this is sand casting which would be often used for larger components, while investment casting can produce great small parts fairly complex in detail. The Boqiao Aluminum casting parts by which we select how to produce the part is crucial, because a good selection between both makes sure that your component will be strong and works well.

There are a few types of casting materials that are typically used in our manufacturing process, those being; Aluminum Iron Steel Bronze All of these substances have particular characteristics that are good for certain uses. Aluminum, for example is really light and easy to machine and hence ideal where parts have to take a lot of strain but can be as light as possible. But it is very strong too for stronger part loading iron can be used.

The strength of a Boqiao cast part is hugely dependent on the design. If for example, we modify the shape or size of a part, it could affect how strong and durable it is. Also, the placement of supporting features such as ribs or bosses can assist in better dispersing stress along the part which makes it more able to withstand pressure.

Using design software known as CAD (Computer-Aided Design) can make cast part making process a little easier. This software lets us experiment with variations in a design before we cast the part Through testing various styles of designs and shapes, we are able to determine the ideal form that allows performance while maintaining durability. Just making the right design choices can significantly impact how well parts work and for been they will run.

With further advances in technology, new and innovative ways to cast parts are being created. The development of 3D printing, or additive manufacturing as it is alternatively known — one the most revolutionary methods. It is a process of creating parts layer by layer using digital designs that are capable to produce very detailed and intricated Boqiao Gravity die casting machines pieces which would be otherwise impossible or too expensive with older methods.

One of the other advanced casting methods is Investment Casting. Process used: Investment casting (uses a ceramic shell that can make very detailed parts with smooth surface finishes) This Low Pressure die cast machines is perfect for creating complex shapes and internal features that are difficult to make any other way.

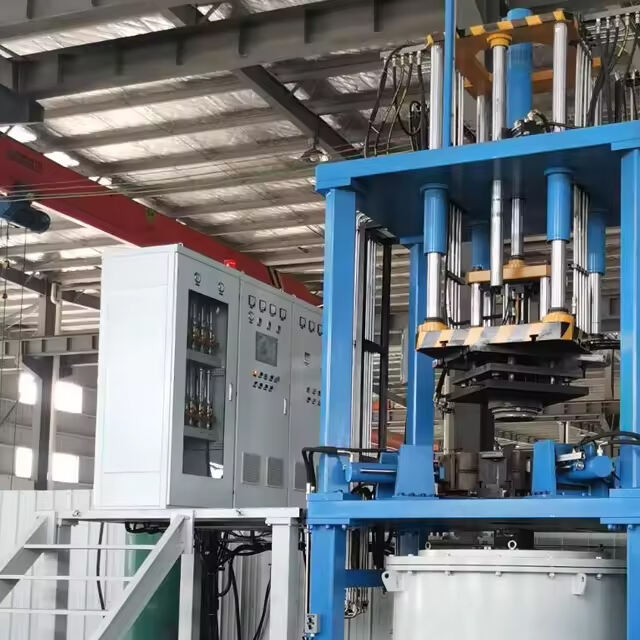

BoQiao's Gravity Casting Machine has a compact design, which makes it a good choice for many manufacturing settings. Its superior performance ensures efficient and precise casting, and its user-friendly interface makes the production process, allowing operators to achieve optimal results with little training. This multifaceted machine is widely used in a variety of industries, including motorcycle components auto parts, auto parts, Casting mechanical, and engineering machinery. The durability and affordability make it a valuable investment for businesses seeking solid casting solutions. The machine is well-loved by its customers due to its constant quality, ease of operating and maintenance, and the increased efficiency.

Our Casting mechanical has sold and manufactured over 2, 000 units from 1999. Reliable quality and excellent service make our company enjoy a great reputation among customers. In addition to sales in every city and province across the country Our products have also been offered to Southeast Asia, Africa South America, Middle East and other regions, and have been a great success by customers. Based on the premise of win-win and cooperation, sincerity and honesty, BoQiao will continue to pursue the path of professional development and continuously improve products and services to better meet the demands of customers. The need to assist customers in creating more value.

In 1979 we started our journey in the industry of cast iron with the purchase of casting materials This was the beginning of our experience and our presence on the market We've established lasting relationships with our clients over the years offering top-quality products and offering exceptional customer service In 1997 we expanded to include the manufacturing of industrial electric heaters This move was a strategic one that allowed us to provide more complete solutions to our clients addressing their growing demands for efficient and reliable heating equipment Our determination to provide quality and innovation distinguished us from the competition By 2002 we'd further diversified our offerings by introducing the production of casting machines This expansion allowed us to offer a wide array of casting options from materials to machinery and ensure that our customers could rely on us for all their casting needs Our vast experience and comprehensive understanding of the industry have established us as a trusted company for companies looking for top-quality casting equipment and support Since our beginning we've remained committed to continuous improvement and client satisfaction which drives us to change and evolve to the ever-changing Casting mechanical

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various Casting mechanical, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer customers all kinds of overall solutions and turnkey project services, such as technical consultation, equipment selection, mold manufacturing design, process development as well as operation training and much more. We are confident that our products will create value to our customers. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.