×

×

Innovative Approaches to Metal Melting

During this process, they have also found out ways that the machine can be used to melt the metal and produce as much efficiency as possible. For example, some of the latest machines use induction melting whereby a special magnetic field is built into them. This technique is interesting because it involves heating metals through electromagnetic fields that do not come into physical contact with them. It also has water-cooling systems in its other machines so that metals don’t overheat when being melted. Overheating is risky for both the equipment and the metal.

Various changes have taken place in technology since metal melting equipment was first manufactured up to now. Compared to before, Boqiao metal melting machines seem safer and more efficient these days. Hand ladling has become a thing of the past since almost all machines are automated and linked by computers which monitor every bit of process going on during melting stages. Computer controls are there to help you manage everything including whether your machine may actually work properly or not. Therefore, it eradicates employees' concern about how well their machines are functioning for melt away processes consequently allowing them concentrate on their own assignment instead

Considerations come into play when thinking of investing in a Metal Melting machine for your business. For instance, do you think about scale — what size will be the machine? If there are only small parts to be melted, then a smaller machine is sufficient. In contrast, if you want to melt larger pieces of metal, then it will require a bigger machine to perform the task. It is also important to consider which type of metal will be melted as some machines work better with specific metals than others. Lastly, find out how much the machine costs and what kind of maintenance is required for it to operate continually. Before you purchase Boqiao melting machine ensures that the price does not exceed your budget and can still be maintained in future years.

At that time, the metal can be remolded and transformed into different objects. One of the common uses of molten metals is casting. Boqiao metal melt machines involves pouring melted metal into a pattern and then cooling it to a solid form. After this action, a metal object is formed inside the mold. Casting methods differ on each other depending upon kind of mold used to make desired cavity in cast piece.

Forging Fire Another way that melted metal is utilized happens to be called Forging. It consists in heating up the metal, shaping it with hammer or press afterwards. These are mostly used in producing heavy duty metallic things like tools, machine parts which need immense strength.

Since 1999, our company has Metal melting machines and sold over 2000 units. Our company has a stellar reputation among its customers due to our reliability and quality as well as excellent customer service. In addition to selling in all cities and provinces across the nation Our products have also been offered to Southeast Asia, Africa South America, Middle East and many other locations, and have been a great success by customers. Based on the business model of win-win and cooperation, honesty and sincerity, BoQiao will continue to pursue the path of professional development and constantly improve products and services to meet the development of customers. It is essential to help customers create more value.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly Metal melting machines of product specifications. We provide a variety of turnkey services, which includes technical assistance, equipment selection and manufacturing and process design, as well as training and operating. We can help our products bring value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.

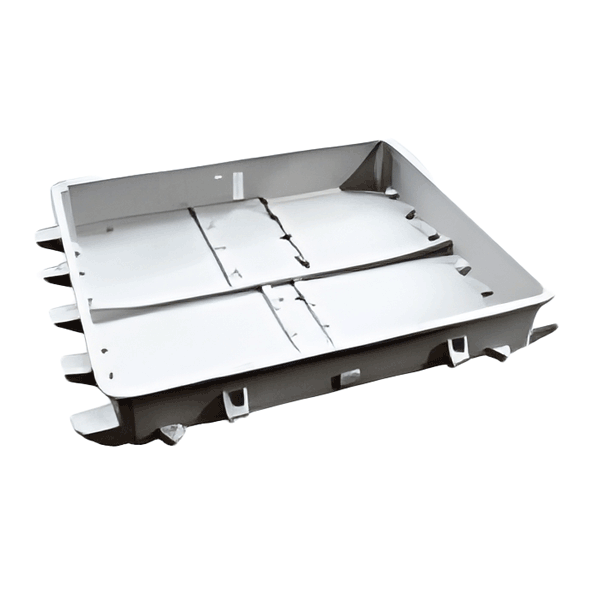

The BoQiao gravity casting machine is Metal melting machines with a small structure and is a perfect choice for various production environments. Its high-performance makes for accurate and efficient casting and the user-friendly design makes the production process, allowing operators to attain the highest quality outcomes with only minimal training. This multi-purpose machine is used in a variety of sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it an investment worth making for companies looking for reliable casting solutions. It is praised by customers for its dependable quality, easy operation and maintenance and increased production.

In 1979 we started our journey in the field of Metal melting machines through the purchase of casting materials This was the start of our knowledge and presence in the marketplace Through the years we've built long-lasting relationships with our clients by providing high-quality products and exceptional service In 1997 we expanded our business to include manufacturing of industrial electric furnaces This strategic move allowed us to provide more comprehensive solutions for our clients and satisfy their increasing demand for dependable efficient heating equipment Our commitment to innovation and high-quality during this time period stood us out in the competitive landscape By 2002 we diversified our product offering by moving into the manufacturing of casting equipment sector This expanded our capabilities to provide a complete selection of casting solutions from materials to machinery to ensure that our clients could trust us with all their casting needs Our experience and extensive knowledge of the field have earned us the reputation of a reliable supplier for companies seeking top-quality casting equipment and services We've always been committed to customer satisfaction and continuous improvement This has enabled us to evolve and adapt in a market that is constantly changing