×

×

If this is the case with your product as well, you are likely using die casting aluminum for a variety of reasons — most notably manufacturing. Used for things like cars, toys, and airplanes – The Process of Making Injection Molded Plastic Parts. Well, in this article we are actually going to look at the world of Boqiao die casting aluminum and find out why it is such a great choice for manufacturing your own unique items.

Advantages of Die Casting Aluminum

There are many advantages when using die casting aluminum to make three products. One of the many reasons aluminum became so popular is that it has higher strength than many other materials. That alone means that things created by with die casting aluminum are hard wearing and long lasting, very little implies damage easily. This is a strength that nobody would appreciate, but many Payout users like doing it for the main reason they know their product would last for decades. Weight — Aluminum is extremely lightweight, which has another imperative benefit. This property makes them relatively easier to carry and use more convenient items made from that particular material, especially at those times when it goes towards toys or parts inside automobiles.

When products are made using die casting aluminum, it is produced at a very strict and steady method. That ensures that every part is made identical each and of the time was produced. We need something more consistent and we want it today, especially for parts that must fit perfectly such as in a car engine or airplane. Just the slightest variation in size or shape could mean a disaster. For instance, it could trigger engine failure or cause the airplane to not operate accordingly. Which is why the utilization of technology for Boqiao Aluminum die casting in place to make sure it all appears seamlessly.

A great advantage of die casting aluminum is that it allows for large no. That is because aluminum can be melted and shaped in a mold to any form intended by the owner. This enables the production of some genuinely excellent and intricate shapes most likely not achievable with other products. Complex shapes or special projects that require unique designs can be easily achieved with Boqiao die cast aluminum such as the intricate features in addition to sturdiness.

One other major benefit of using die casting aluminum is that it saves money for producing large quantities while at the same time the objective quality remains high. You can do this because the die casting process is relatively very fast and lets many parts to be created everywhere easily. The faster you can make plenty of the same things, the cheaper it will be on average. Since this cost is passed on to consumers as well, it will be good not only for the manufacturers but also the products we buy because their prices can drop. Therefore, when items are being produced in bulk quantities die casting aluminum is the best approach.

Furthermore, we should not forget that there are significant environmental advantages to die casting aluminum. This is better for Earth as aluminum can be recycled countless of times, whilst retaining its purity or strength. Recycling aluminum cuts down on trash and saves natural materials meaning it is the more environmentally friendly option. Using aluminum allow us to produce less rubbish and keep our environment clean for generations. So, it really is a pretty good choice compared to other, more harmful or waste-producing materials.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Die casting aluminum customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

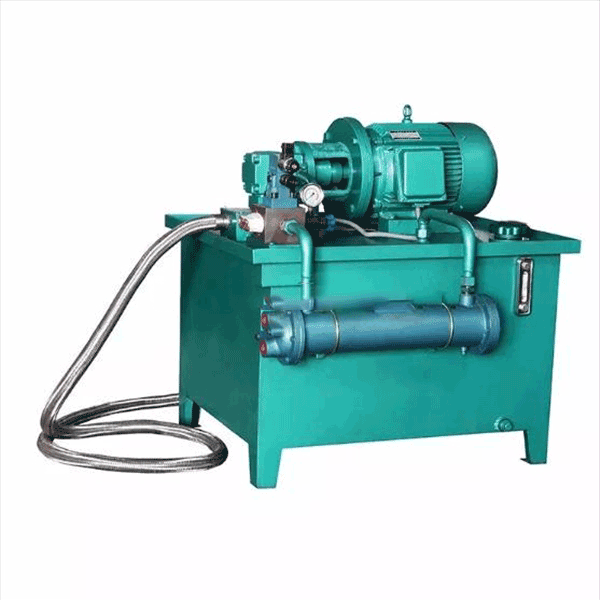

The BoQiao gravity casting machine is Die casting aluminum with a small structure and is a perfect choice for various production environments. Its high-performance makes for accurate and efficient casting and the user-friendly design makes the production process, allowing operators to attain the highest quality outcomes with only minimal training. This multi-purpose machine is used in a variety of sectors, such as motorcycle parts auto parts, auto parts and electric power fittings as well as engineering equipment. Its durability and cost-effectiveness make it an investment worth making for companies looking for reliable casting solutions. It is praised by customers for its dependable quality, easy operation and maintenance and increased production.

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, heat treatment equipment and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include technical advice, equipment selection and manufacturing and process design, as well as training and operations. We are confident that our products will create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, Die casting aluminum and other professional castings production enterprises.

Our journey into the field of casting began in 1979 with sales of casting materials that laid the groundwork for our experience as well as our market position Over the years we have built lasting relationships with our clients through offering high-quality products and excellent service In 1997 we expanded our services to include manufacturing of electric furnaces for industrial use This move was a strategic one that allowed us to offer more complete solutions for our clients and satisfy their increasing demand for high-quality reliable heating equipment At this point our commitment to quality and innovative thinking made us stand out from the competition In Die casting aluminum we had further expanded into the manufacture of casting machines We were able to provide the full spectrum of solutions for casting including the materials as well as machinery This enabled us to become a one-stop store for our customers with casting needs Our experience and extensive knowledge of the industry has made us a reliable partner for businesses seeking top-notch casting equipment and services We've always been devoted to customer satisfaction and continuous advancement This has driven us to evolve and adapt in a marketplace that is ever-changing