×

×

Did that item ever occur to you or no? The need component of any number machines in the gearbox. This gearbox assists in transferring power from motor to machine. This Boqiao is the joint that links the motor to the other side of your machine. Without the gearbox, machines will not function properly or may completely cease to work.

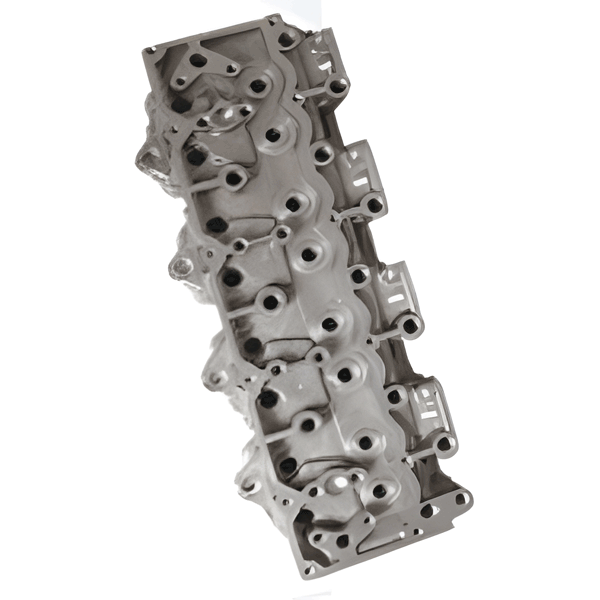

Many small parts fit together inside of the gearbox to make it function like a world-class team. Casting is a major component in this unit. Casting is a sophisticated method in which the liquid substance gets poured into molds and then solidified to shape a particular object. The Gravity die casting machines liquid in question is typically metal, meaning it ends up being remarkably durable — perfect for gearboxes.

Strength: Gearbox castings are highly durable Metallic material: This Boqiao could be steel or aluminum, and these are known for their durability even in the most challenging of conditions. They also tend to be more suitable for use in machines that need to run continously and reliably each day.

Affordable: Gearbox casting is an efficient method of developing dependable parts at a fraction the cost. The Low Pressure die cast machines pieces are molded so a lot of the similar parts can be very quickly produced. Factories can save valuable time and money using this, which is vital for smooth running of any business.

Mould: The Boqiao mould is in very important for the design of gearbox casting and must be well designed. It needs to fit in the BQ melting furnace machine and strong enough to handle all forces it faces. You should also consider its designs so you can immediately detect what problems would your building encounter in the future.

Types of Sand casting: This is one method from the more commonly used ones. This BQ quenching furnace mold is created using sand and subsequently liquid metal is poured into it. Once the metal has been allowed time to cool and harden, it is a matter of removing the sand being cleaned up until all that you left behind was that perfect casting we talked about. This one is straight and simple to the point technique.

Investment Casting — This technique uses a wax mold that is coated in hard inner ceramic shell. That way when it is heated the wax will melt out, leaving a void. Hot metal is then poured into the shell, providing a precision casting. This Aluminum casting parts way is reliable good method to make very detail piece.

BoQiao's gravity cast machine is a compact design, which makes it a good choice for a range of manufacturing settings. The Gearbox casting of the machine ensures accurate and efficient casting while its user-friendly system simplifies the production process, which allows users to get the best outcomes with only minimal training. This multi-purpose machine is used in a variety of industries, such as motorcycle parts automobile parts and electric power fittings as well as engineering equipment. The durability and affordability are a great investment for businesses seeking solid casting solutions. The machine is highly regarded by customers for its consistent high-quality, simple operating and maintenance, and the increased production.

Our company has sold and manufactured over 2, 000 units since 1999. Our company has a stellar standing with its customers due to our reliability and quality as well as Gearbox casting customer service. The company has sold its products to Southeast Asia and Africa South America and the Middle East. Customers have also been satisfied with the service and quality. Customers need to be able to create more value.

In 1979 we started our journey in the field of Gearbox casting through the purchase of casting materials This was the start of our knowledge and presence in the marketplace Through the years we've built long-lasting relationships with our clients by providing high-quality products and exceptional service In 1997 we expanded our business to include manufacturing of industrial electric furnaces This strategic move allowed us to provide more comprehensive solutions for our clients and satisfy their increasing demand for dependable efficient heating equipment Our commitment to innovation and high-quality during this time period stood us out in the competitive landscape By 2002 we diversified our product offering by moving into the manufacturing of casting equipment sector This expanded our capabilities to provide a complete selection of casting solutions from materials to machinery to ensure that our clients could trust us with all their casting needs Our experience and extensive knowledge of the field have earned us the reputation of a reliable supplier for companies seeking top-quality casting equipment and services We've always been committed to customer satisfaction and continuous improvement This has enabled us to evolve and adapt in a market that is constantly changing

Nanjing BoQiao Machinery Co., Ltd is a professional designing, manufacturing, selling manufacturer of various casting machinery, Gearbox casting and industrial furnaces. Existing products including gravity casting machines, low-pressure casting machines, melting furnaces, annealing furnaces, quenching furnaces, aging furnaces and transverse magnetic furnaces and others have formed 18 types and nearly 100 kinds of product specifications. We offer a range of turnkey solutions that include the technical support, selection of equipment and manufacturing processes, design, training and operations. Our products can create value for our clients. Products are widely used in: electric power fittings, motorcycle parts, auto parts, new energy, electronic and electrical, high-voltage switch, engineering machinery, aerospace castings, fans, household appliances and other professional castings production enterprises.