Aluminum is one of the most utilized metals in the global scale. Producing aluminum in a process that saves energy and contributes to protecting planet Earth is crucial. Boqiao knows this and is working on ways of doing it with less power, but still have strong and useful products to show for it. One way is through gravity casting. It leverages fantastic powers of nature already, it’s gravity shaping aluminum which could minimize waste and energy so. Not only is this practice good for the environment, it can also save businesses money due to reduced use of electricity and materials. Focusing on hig-efficient gravity casting, Boqiao provides solutions that answer to today´s demands, but have one eye on the world of tomorrow

There's More to It Than Gravity Casting and Aluminum Quality

For Boqiao, gravity casting is ultimately about creating pieces of aluminum that are strong while using less energy to do so. Gravity casting involves pouring melted aluminum into molds and letting gravity push the material into the shape. This process does not require additional machines or pressure that are energy consuming things. One key to Boqiao’s approach is carefully regulating the heat of the aluminum and the molds. If the metal is too hot, or the mold too cold, it squanders energy and can lead to flaws in the finished product. By getting everything so precisely right, Boqiao cuts down on the amount of re-making he has to do, which in turn saves even more energy. Special molds that keep the heat or cool down uniformly are also used at times. This helps copper and aluminum set up uniformly, which minimizes the chances for cracking or weak spots. Also, when casting in production volume, Boqiao creates molds that can be used numerous times. It minimizes material consumed and reduces waste. For instance, in one project Boqiao developed a new mold coating that made casting faster and more efficient, reducing energy use by almost 20%. The company also plays with shapes to encourage the aluminum to better flow into the mold. That's fewer defects and less scrap metal, which in turn saves energy and brings down costs. While gravity casting may appear simple, it requires much caution and intelligent choices to make the process energy-efficient and creating good quality aluminum parts for wholesale customers

How Gravity Casting Can Improve Efficiency in Sustainable Aluminum Production

When making aluminum in an earth-friendly way, gravity casting is a big player. Using gravity, a natural force, instead of machines that require great deal of power to work, is an “elegant” way for Boqiao’s team to keep the use of energy low. Gravity casting helps in part by minimizing the need for additional heating or cooling processes. It typically requires less electricity than other processes because the metal cools in the mold on its own. And gravity casting produces less metal waste, too. When aluminum slowly fills into a mold, it is less likely to spill or form rough edges that must be cut away. This results in more of the raw metal being turned into the final product, which is good for the environment. Boqiao also plans the entire casting process to consume energy more effectively. For example, if they put molds close together, the oven can heat them all up at once rather than one by one; it saves power. Because the company recycles so much of its scraps back into the production loop, there is less need to mine new material, a big energy saver. At times, the team figures out how to reuse heat that has been stranded by casting in order to warm other areas of the factory. This mode of thinking demonstrates just how carefully Boqiao avoids wasting anything. This isn’t just about saving money, it’s a matter of respect for the planet. Gravity casting also makes it possible to produce parts that last longer and require fewer repairs or replacements. Stronger aluminum goods lead to less waste over time. Boqiao’s dirigible showed that when factories deploy gravity casting in the proper manner, they are capable of producing aluminum — sustainably and efficiently. This enables them to keep meeting the demands of customers for high-quality materials while also supporting environmental goals

Why is Gravity Casting the Best Process for Green Aluminum Manufacture

Gravity casting is a unique process of producing aluminum parts by simply utilizing the natural force of gravity to fill molds with molten metal. This approach has become increasingly popular because it saves energy and is more environmentally friendly. There is a need to heat a lot in the production of aluminum, which involves melting metal. Gravity casting consumes less energy than other methods since the metal does not need to be forced into molds with additional tools. This uses less electricity and fuel, to the benefit of cuts in pollution and costs

Gravity casting is also environmentally friendly because there is less waste output. The process is heavily automated, and the quantity of aluminum that spills or becomes scrap is minimal. This ways companies like Boqiao saves materials and can recycle even more metal. Recycling aluminum requires far less energy than converting new aluminum from raw materials, and gravity casting helps conserve natural resources by minimizing waste

Additionally, gravity casting produces stronger and more durable aluminum parts. And these parts last longer and don’t need to be replaced as often. This helps reduce the need for production of new materials, which is more energy and resource intensive. The method also offers good design flexibility, and it can be used to make shapes that require minimal material but are strong. This builds a stronger universe for aluminum to prevent it from having such an exhaustible life cycle

Gravity casting suits a large variety of industries, due to its applicability for both small and big parts, for being greener. Companies like Boqiao use this process to create aluminum parts that meet stringent environmental requirements. In opting for gravity casting, they can provide customers items that have been produced in a manner that respects the planet. This helps create more sustainable production of aluminum, which is important for our world’s future

Find The Gravity Casting Issue And How To Solve It In Wholesale Production

While gravity casting is an efficient method of using less energy to make very strong aluminum components, there are roadblocks – especially if you’re making a lot of products in one go, like by the truck. This is but one of many problems that are commonly encountered in temperature control of the molten aluminum. If the metal is too hot or too cold, it may not fill into the mold properly and produce bad parts or weak areas. To address this, Boqiao relies on special temperature control systems to maintain the metal at its ideal heat. This ensures that the entire part is strong and good looking

Another challenge is ensuring that the molds have a long life. Molds are used repeatedly in large production runs, and they can grow worn or break. To address this, Boqiao uses high-grade mold materials and coating methods to prevent heat and metal damage to the molds. This means you can use the mold to make thousands of castings and still get a perfectly product, thus saving money and reducing waste

Occasionally, air bubbles or micro holes can be created in the aluminum during casting. These flaws impair the strength of the parts. Boqiao addresses this by fixing the input of the flow of molten metal in the mold. They are careful to design the molds so that the metal flows evenly and with low velocity, which reduces entrapped air. They also use vacuum systems or special vents to assist in drawing the air out during casting

And it can be hard to keep speed of production going with the quality, ultimately. Boqiao relies on the training of workers and smart automation tools to hasten the process without errors. This balance enables them to produce many parts quickly for wholesale orders while adhering to strict standards

By knowing and solving these problems, Boqiao make gravity casting to be an reliable and energy saving way for making lager quantity of aluminum parts. This can help consumers get good products and support green manufacturing

Where to Get Low-Price Aluminum Gravity Casting Machines for Mass Production

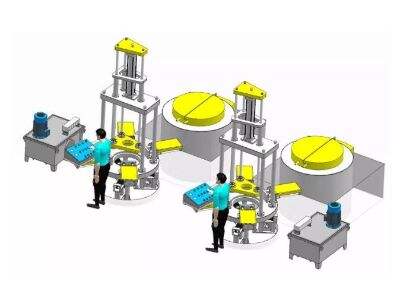

For businesses interested in making large scale aluminum parts using gravity casting, the type of equipment used is precious. High-quality equipment helps conserve energy, produces strong parts and minimizes costs. Boqiao understands that when buying the best machines, it can be a big decision and thus important to select suppliers who will offer you quality and value for money

When searching for gravity casting equipment, the first to search for is energy efficiency. Less power hungry machines lower cost of production and are more environmentally friendly. Boqiao operates with machinery and equipment featuring efficient heating systems and insulation to reduce energy use. This means that companies can produce more parts without wasting fuel or electricity

Second, the apparatus must be reliable and simple to service. In production-breaker orders, machines that operate continuously and without fault save time and eliminate costly repairs. When Boqiao choose casting machine, it is a sturdy material and light design. This, in turn, makes them easier to clean and repair if something goes bad. It also keeps production races from taking long breaks between each episode

Also, the dimension and flexibility of tools is important. Closed-loop gravity casting machines are available in various sizes with respect to the parts produced. Boqiao provides a range of machinery that runs the gamut from small to very big moulds, and which can be customized for various shapes and weights. Such flexibility is important for growing companies that want to make more types of aluminum parts without buying new machines

Finally, price is always an enormous factor. Boqiao is referring to helping you find the right equipment at a price that matches your budget, but also maintains high-quality standards. It is also important to buy from reliable suppliers, who provide good warranties and after-sale support. In enabling companies to defend their investment and get help when they need it

With Boqiao‘s recommendations, companies may select affordable and economical gravity casting equipment that is energy-efficient and in high demand in today’s market to produce large-volume aluminum parts sustainably and affordably. This contributes to a greener future and a thriving business

Table of Contents

- There's More to It Than Gravity Casting and Aluminum Quality

- How Gravity Casting Can Improve Efficiency in Sustainable Aluminum Production

- Why is Gravity Casting the Best Process for Green Aluminum Manufacture

- Find The Gravity Casting Issue And How To Solve It In Wholesale Production

- Where to Get Low-Price Aluminum Gravity Casting Machines for Mass Production

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY