Low Pressure Die Casting is a special way to produce aluminum engine parts that enables them to stay strong for longer. Instead of casting metal rapidly, and letting it cool rapidly, the process slowly forces molten aluminum into a mold using low air pressure. This slow, steady flow helps the metal get into every corner, creating parts that are less likely to have holes or cracks. If the parts that Boqiao produces in this way sound like an engine, they are tough and dependable.

Buyers Should Consider Low Pressure Die Casting

If you are purchasing aluminum engine parts en masse, you certainly hope they hold up. Low pressure die casting is a good aid for that because it gives the parts more density and strength. Liquid metal pours into the mold slowly and methodically, with fewer air pockets in the part. Air pockets create weak spots, which can snap or wear down more quickly. Boqiao’s application of this casting helps ensure that the aluminum is dense and packed tight as a solid block, so the parts can withstand high heat and pressure without cracking inside an engine.

ALUMINUM DIE CASTING FOR ENGINE MOUNTS

How you make aluminum engine parts matters a lot, particularly if you’re ordering lots of them at one time pressure die casting machine is attractive because it marries quality with productivity. Unlike other processes that flow metal rapidly and can create rough surfaces or weak areas, low pressure die casting fills the mold in a controlled manner. These are nice because the pieces will have flat sides and less likelihood of defects. Boqiao says this is significant because it saves time and money from the extra cost of polishing or fixing. This casting approach also minimizes the amount of metal waste. When metal streams slowly, it cools more effectively and fills the mold more fully, preventing as many pieces from getting scrapped.

Aluminum Engine Parts & How LPDC Solves

It can be challenging to produce engine parts out of aluminum. Aluminum is a lightweight metal that can help make cars faster and more fuel efficient. But many problems arise when companies try to mold pressure die casting machine for aluminium into engine parts. One challenge is that aluminum’s melting temperature more than 1,200 degrees Fahrenheit makes it difficult to pour the material without making a mess. Occasionally, the metal cools too rapidly or too slowly, resulting in cracks or weak areas in the components. Sometimes, air bubbles are captured in the aluminum and the parts are less strong.

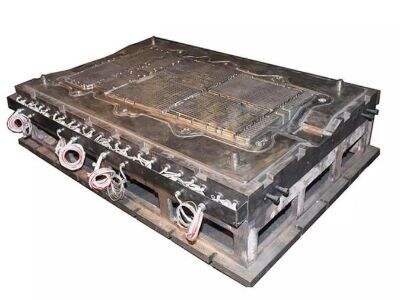

Aluminum Engine Parts low pressure die casting

If you're in need of aluminum engine parts, searching for where to buy them is crucial. You want parts that are reliable yet affordable. Boqiao is an ideal choice for obtaining affordable aluminum engine parts produced by means of pressure die casting machine. This keeps prices down so you save. What’s more, Boqiao only specializes in producing aluminum parts in the highest quality. Before we send them out, we thoroughly examine every part to ensure they abide by a high standard.

Whether you want a small run or parts for large quantity orders, we can help. Flexible and quick That way, the projects can go on uninterrupted. And we can tailor parts to specific engine designs, if necessary. With our rich experience in low pressure die casting, we can also provide you some suggestions on design to make the parts stronger and more easy for production.

Innovation in Aluminum Engine Part Die Casting:

The new inventions in low pressure die casting for the wholesale buyers who are purchasing here large quantity of aluminum engine parts. These innovations are producing better parts that can be made more cheaply and rapidly. At Boqiao, we adhere to the advanced technology and provide our buyers with best services. Better temperature and pressure control during the casting process is one major new development. This allows aluminum to flow into molds more smoothly, resulting in fewer defects and stronger parts.

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY