Low pressure die casting is a special process for making items, like car and truck engine parts out of metal. This process is crucial to create high quality parts with less material. At Boqiao, our attention is on delivering materials that are strong, but not wasteful. Not only is this environmentally friendly, it also saves car manufacturers money. Lower pressure die casting results in less waste of material for everyone

How Low Pressure Die Casting Reduces Material Waste When Manufacturing Automotive Parts

LÖVERKSON low pressure die casting for automotive components. Traditional methods, which can leave a lot of scrap metal, are not used here; instead low pressure die casting involves special techniques used to force metal into the molds. It allows the mold to be filled entirely—minimum portions of metal go unused. This is akin to filling a cup of water; you just need to pour slowly and gently until it reaches all the way without overflowing. In an instant, low pressure die casting fills every inch of the mold—so there’s less material wasted

For instance, when producing engine parts such as cylinder heads, the method makes it possible to create very specific shapes. If we cost out these parts with regular casting, we could perhaps get a lot of excess metal that we would have to waste away. It not only raises costs, it generates waste. With low pressure die casting, we do it right the first time, and save both on material and money

One other advantage is that low pressure die casting can be used to produce very strong, but lighter parts. In cars, this matters because lighter parts make for better fuel economy. For example, if we design a lightweight engine bracket, it’s not just about using less metal, but it also means the car can travel further on less gas. At Boqiao, we pride ourselves on the way this approach empowers our customers to build better cars which are also kinder to the planet

Advantages of LPDC in the Automotive Industry Commercial Reasons

What are the Advantages of Using Low Pressure Die Casting? There are many benefits for companies that manufacture cars. Firstly, it may provide for quicker production runs. But if an auto maker needs a lot of parts posthaste, Boqiao can churn them out. Because the process is fast, manufacturers can soon receive their parts and get back to work on their vehicles without long delays

There are also financial benefits. Since there is less waste, companies spend less to purchase raw materials. This is even more important in the dog-eat-dog automotive industry where every cent really matters. Through low pressure die casting, auto manufacturers can reduce their costs and pass these savings down to the customer

Quality is another big plus. Upon completion, parts fabricated with low pressure die casting have consistent finishes and tolerates – so they fit together perfectly. This is of great importance to car safety and performance. “If you have a piece that doesn’t fit well, it prevents things from sliding into place,” she said. Boqiao makes sure that the parts we make are high quality and car makers can trust what they put in their cars

Selection For The Best Low Pressure Die Casting Supplier Of Automotive Parts

The choice of the suitable producer for reduced stress pass away directing is actually very crucial as well as crucial in automobile elements manufacturing. The very primary thing towards develop when selecting a provider is actually the degree of their expertise. More mature companies such as Boqiao have more understanding around the procedure, as well as often create higher-quality components. You will also want towards consider the type of devices they are actually utilizing. Brand-brand new devices can easily produce components quicker as well as much a lot extra precisely, an essential capability towards car manufacturers. The various other point one should take a check out is actually the high top premium of components they are actually creating. Demand examples, or even look for out reviews coming from various other clients. This is actually to allow you understand exactly how great they are in production their item. It is useful towards have actually an comprehending of exactly how they manage big purchases, as well, if you require 1000 parts at once. Likewise make sure towards ask about their delivery opportunity. You do not desire to have towards wait on your components when you require all of them, therefore a provider along with a background of on-time shipment is actually an and also. Likewise view if they have the ability to deal support after the purchase. Lastly, have a look at the cost however bear in mind that the most affordable is actually not necessarily the very best

What are the methods to positively impact on material utilisation in low pressure die casting

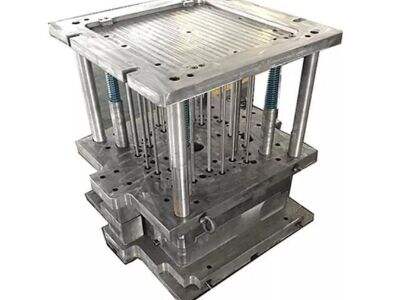

For automotive parts for example the material efficiency plays a crucial role in low pressure die casting. One trick that provides some assistance here is by using the right molds. A mold and mildew is actually one thing such as a form steel gets poured right in to. Properly designed, it decreases squander, if the mold and mildew is good. For example, Boqiao is actually creating mold and mildews that suit completely — significance much less of the steel will certainly most likely to waste when items are actually produced. Another is actually command of metal temperature. If the steel is actually as well warm, or even as well chilly, it can easily result in problems — which section may need to be tossed. Preserving the steel at the correct temperature level enables providers towards create higher-quality components, along with much less ditch. As well as let's not forget that reusing ditch steel provides outstanding product effectiveness. Remaining steel coming from the casting process could be thawed as well as recycled. It do not simply conserve the product however likewise the cost. Another very helpful device is actually simulation. This kind of software application can easily allow developers towards view exactly how the steel will flow right in to the mold and mildew prior to it is actually created. This way, they can easily view if certainly there certainly are actually any type of problems and fix all of them, therefore decreasing squander. As well as lastly, educating employees in finest methods can easily create a huge difference. When employees understand ways to use machines as well as products properly, they can easily reduce squander as well as create the procedure much a lot extra effective. With utilizing such techniques, companies like Boqiao are actually capable to contribute towards the manufacturing of high quality automobile components simultaneously as well as create finest use products

Low Pressure Die Casting in Sustainable Automotive Applications

Low-pressure die casting is a key part of how automotive production can become more sustainable. Being sustainable is all about being “green” and responsible with your environment and resources. One of the great things about low pressure die casting is that it prevents wastage unlike other means of production. Because it requires less steel as well as has the ability to create components much a lot extra exactly, there's much less ditch product left behind over. This is great for the atmosphere, since it suggests that much less squander winds up in garbage dumps. That it utilizes much less power is actually another advantage. When firms such as Boqiao utilize low-pressure pass away directing, they have the tendency to find they need much less power for production components. This is actually essential towards reducing their carbon dioxide impact — one thing which helps fight environment alter. Additionally, recycled products could be used in reduced stress pass away directing. A big variety of automobile components could be created along with reused steel, decreasing the demand for basic materials. This is actually assisting conserve natural deposits as well as lessening pollution coming from mining brand-brand new products. Additionally, reduced pressure die-casting can easily offer light-weight items. Decreasing the weight of vehicles creates all of them much less gas parched, a gain for the atmosphere. Vehicles that are actually more fuel effective create less discharges. To conclude, LPDC is a considerable procedure for lasting produce of cars. It allows business such as Boqiao towards make high-quality components, all of while being actually great for the world. Through including focus towards squander decrease, the preservation of energy as well as using message customer products can easily assist our team top much healthier lifestyles for potential productions

Table of Contents

- How Low Pressure Die Casting Reduces Material Waste When Manufacturing Automotive Parts

- Advantages of LPDC in the Automotive Industry Commercial Reasons

- Selection For The Best Low Pressure Die Casting Supplier Of Automotive Parts

- What are the methods to positively impact on material utilisation in low pressure die casting

- Low Pressure Die Casting in Sustainable Automotive Applications

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY