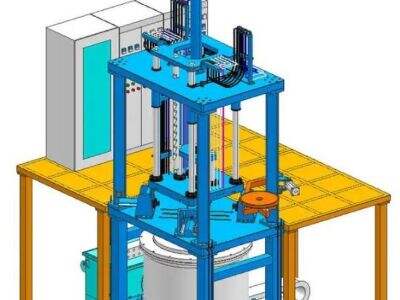

Aluminum is difficult and expensive to work with on a large scale, but rotational casting machines can make it much easier and cheaper. These machines are used to form aluminum by slowly rotating a mold while filled with molten metal that coats the interior uniformly.

Wholesale Large Aluminum Parts

Rotational casting machines are great for producing big batches of large aluminium parts because they combine speed and quality. As the mold rotates, liquid aluminum fills in every nook and cranny equally, ensuring there are no weak spots to fail on Shoals’ parts.

Rotational Casting Machines

For a company that needs a lot of large aluminum parts, rotational casting machines save time and energy. Part of the reason is that these sand casting machine are meant to run for a long time without breaking.

Rotational Casting for Big Parts in Aluminum

Rotational casting is a clever way to produce large aluminum parts without spending a lot of cash. At Boqiao, we are aware that using the appropriate foundry machines and implementing good measures will enable a faster and better factory.

Rotational Casting Large Aluminum Parts

Producing large aluminum parts with rotational casting seems like a great idea, but it can also pose some challenges. At Boqiao we recognize these difficulties and provide a remedy. An issue which is often encountered is the variation of metal thicknesses.

Purchase Dependable Rotational Casting

When a factory is ready to manufacture large aluminum parts via rotational casting, it’s critical to discover reliable and user-friendly machines. Boqiao is a reliable brand that delivers sturdy, quality aluminium injection moulding machine designed to handle larger projects. Good temperature control and strong rotation systems, as well as durable molds are good things to look for in machines.

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY