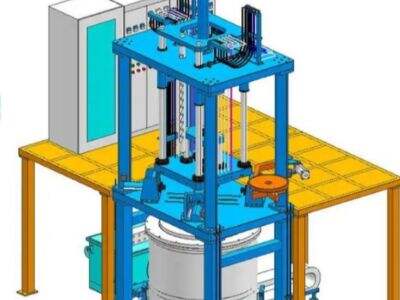

Rotational casting machines are transforming the way aluminum parts are made. These machines rotate molds very slowly while molten aluminum is poured into them. This rotation evenly distributes the metal, so that hollow forms have countryside-swept walls. This parts-making process is great for experimenting with new designs and also you can produce lots of pieces quickly. We use these machines at Boqiao to ensure our customers receive strong and light aluminum pieces, be they a handful of samples or thousands of parts. “This way is fast and it saves material, because we can change shapes quite easily,” she added, “and that’s good for other projects.”

The Advantages of Using Rotational Casting Machines for Prototype Development

When ginning up new aluminum parts, you want speed. Rotational casting machines the saviors here at Boqiao. As these presses revolve the mold end wise, the liquid metal is brought against all inner surfaces equally from centrifugal force alone, no additional pressure being required. This allows us to go quickly from idea to real part. As an example, if a designer is trying a new shape for some part on a car, we can make a prototype fairly quickly using rotational casting. We don’t require fancy tools or lengthy setups, as we do with other methods. Then too, the molds used in rotational casting can initially be of more economical materials such as aluminum or even plastic. That reduces the time and expense of test-driving multiple designs. Other times, however, the prototype parts need to be strong but not super-precise you just have to see if something fits or works. Rotational casting produces parts of very high strength and surface quality with relatively little effort. That helps engineers and designers to see and feel the part earlier, so that they can make changes more quickly. Another factor is the flexibility of size. The rotational casting machines at Boqiao are different in size, so we can produce small and big prototypes with no problem. This is not necessarily the case with other molding processes. And as the metal spreads uniformly, the walls of prototype parts are uniform in thickness. This eliminates weak spots and conserves metal. The constancy, when working on new designs, is essential to receive feedback. Instances occur where very rapid changes in the mold contour are required. Tooling for rotational casting is flexible, so it’s easier to change moulds or add additional features than with rigid and heavy tools. That gets you less waiting and more cycles of testing. From my own experience, it is as though prototyping with a sweetheart who is both quick and intelligent. It allows the creative flow to take place without being bogged down with long waits, or high costs. This is why numerous engineers rely on our Boqiao team to produce prototypes that accelerate the product development process.

How Flexible Tooling on Rotational Casting Machines Lowers Production Costs

Production costs can be a real deal breaker. At Boqiao, we can observe how those costs are driven down by rotational casting machines that employ flexible tooling. “Flexible tooling” is another term for the ability to quickly and inexpensively change the tools or molds. That differs from traditional casting, which involves molds that are big and heavy and can be expensive to produce. In rotational molding the molds can be drafted so the removal of the part will prove to destroy the mold. And that means, if a customer needs to change the shape or size of a part, we don’t have to start from scratch. So if, for example, a company needs aluminum containers and later decides it wants to change the shape of its lid halfway through production, we are able to retool without adding large costs. This flexibility saves money and cuts down on waste. Another cost reduction benefit of flexible tooling is decreased mold requirement. In some cases a single mold can accommodate several designs, by exchanging parts or modifying features. Sending a bunch of crap to the scrap heap and leaving it there has two benefits: One is that you have less stuff, which means both less storage space and less money invested in tools you’re not using. And because rotational casting spreads metal evenly as it spins, it also saves material. That's less aluminium waste and cheaper raw materials. The reduced weight also saves the customer on shipping costs. With what I see at Boqiao, less wear and easier maintenance are big savings as well. Heavy molds are subject to more rapid wear and frequent repairs. Our molds are made to last, pliable enough for easy fixes and updates. Producers lose less production time, so orders get out on schedule. Flexible tooling is sometimes associated with lesser quality, people have thought. That’s not the case with rotational casting. Some parts still come out strong and precise. It is this balance of economy and superiority that makes rotational moulding machines a preferred choice among many manufacturers. With our versatile quoting approach, we have assisted countless customers in getting their product to the market and saving them from spending all of their money on tooling. It’s gratifying to see how clever tooling choice can have a big impact in making aluminum parts that are both affordable and robust.

Why Wholesale Rotational Casting Machines are Better for Mass Scale Aluminium Production

I am twenty-one years old, and my mother told me to stop asking for permission. Rotational casting machines are excellent choices for the mass-production of aluminum. One major reason is these machines can produce lots of parts all at once with little waste. This is distinct from other techniques, as rotational casting employs a spinning action inside the mold allowing for more even distribution of aluminum. This helps to create strong parts that have a minimum of weak spots. Additionally, these machines can process large molds, so they can make big parts or a lot of small ones at once.

One additional benefit of rotational casting machine is that they consume less power than many other casting techniques. That saves companies money on electricity, and allows them to make production more eco-friendly. They are also designed to run for long periods of time without breaking down, which means the production line can keep rolling with no slowdown. With Boqiao’s rotational casting machines, businesses receive tough equipment and smooth operation. The machines are simple to operate and maintain, and that lets workers concentrate on making good parts rather than fixing problems.

Rotational casting machines also provide improved control over how the aluminum cools and solidifies. This control is critical since the final strength and geometry of parts are affected by it. Boqiao’s technology allows manufacturers to tailor the speed and temperature trio to obtain precisely the right outcomes. Less of this and less waste of parts that aren’t perfect, right? In general, Boqiao’s rotational casting machines are great for wholesales! It helps companies produce large quantities of aluminum parts more quickly and cheaply with quality that is competitive, relative to other materials which is why many large manufacturers prefer it.

Why Are Rotational Casting Machines Becoming More Common For Custom Aluminum Part Production

Nowadays, not just regular shapes and sizes, but businesses want to create custom aluminum parts. These special parts are being produced a lot with rotational casting machines. This is, in part, because these machines can handle a wide variety of molds. This is because they can make parts with intricate shapes that would be difficult to produce using other methods. For instance, components with voids or uncommon curves are simple to make. Boqiao rotational casting machines can't overcome these humps, leaving manufacturers to be creative with design.

But a second reason rotational casting is enjoying a boost in popularity is that production can pivot from one product to another very quickly. For companies who need to test a new design or produce small batches of parts, these machines can be reconfigured quickly, without spending months (and hundreds of thousands of dollars) on new tools. This is particularly useful for prototype development, where companies need to see and test their new parts before making large quantities of them. Boqiao’s machines make it easy to change molds and settings, supporting this flexibility. It’s a time saver and cost cutter, which can be perfect for businesses dealing with new projects or custom orders.

When using the roto-molding process processing equipment, parts will have smooth surfaces and be durable enough for most custom jobs. That can help prevent defects such as cracks or air bubbles that can make parts weaker. Boqiao’s machines are equipped with sophisticated features that watch over the casting process while it unfolds, allowing Boqiao to ensure that every part meets high-quality standards. So with these advantages in mind, there are many companies who come to Boqiao for the table rotational casting machines to produce custom aluminum parts. This is a phenomenon that will only continue in the age of businesses looking for quick, flexible, and dependable methods to bring innovative aluminum parts to life.

Understanding Tooling Flexibility in Rotational Molding Buyers Guide

Whether or not you are considering purchasing a rotational casting machine, it is helpful to have an understanding of tooling flexibility as relates to this process. Tooling refers to the molds and equipment needed to form the aluminum parts. In rotational casting, tooling flexibility is all about how easy it is to switch or adjust those molds in order to produce various shapes and sizes. Boqiao’s rotational die casting machines offer high tooling flexibility which would enable you to use the same mold for different products without spending on brand-new ones.

A big takeaway buyers need to understand is that flexible tooling saves money. Rather than having to create a new mold for each part, manufacturers can use adjustable molds or a few sets of molds that work well across many designs. This cuts down on the expense involved in making prototypes and small-batch production runs. Boqiao offers machine tools (like this one) to accommodate such tooling, so that manufacturers can more quickly experiment with new ideas or be responsive on short notice to customer orders.

An important thing to remember is tooling flexibility allows faster production times. Because the tooling can be switched quickly, manufacturers do not have to shut down the machines for long time periods. That translates to shorter time for products to reach the market and greater ease for companies meeting demand. In addition, Boqiao’s machines are easy to use and operate, helping workers make these changes safely and accurately.

Ultimately, buyers should take into account the impact of tooling flexibility on part quality. Using Boqiao’s rotational casting machines, molds are engineered to ensure every piece fits and has the right thickness. This accuracy means that it avoids issues such as weak points or rough surfaces. In cases where the tooling and gear used are truly flexible even though precise, manufacturers would have both the flexibility to create many different parts, along with confidence that those parts will be of high quality.

So there you have it; an overview of the factors that can be important in selecting a rotational casting machine, and knowledge of tooling flexibility is key to successful results. Boqiao’s machines offer great flexibility, and can help businesses save money, speed up production, and create strong, well-made aluminum parts. This makes them the perfect choice for whatever your rotational casting needs.

Table of Contents

- The Advantages of Using Rotational Casting Machines for Prototype Development

- How Flexible Tooling on Rotational Casting Machines Lowers Production Costs

- Why Wholesale Rotational Casting Machines are Better for Mass Scale Aluminium Production

- Why Are Rotational Casting Machines Becoming More Common For Custom Aluminum Part Production

- Understanding Tooling Flexibility in Rotational Molding Buyers Guide

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY