Sustainable manufacturing is booming fast because people want to make stuff in ways that don’t bode destruction for the planet. One way to accomplish this is by employing rotational casting machines to create aluminum components. Aluminum is relatively light, strong and recyclable. With rotational casting you can produce parts that match the shape and size very closely right off the bat. In other words, less wastage and fewer work fixing or cutting the parts in the after-master. Boqiao sells these special machines, which enable factories to save energy and materials. The process is smart, clean and helps companies produce better aluminum parts while caring for the earth

How Rotational Casting Delivers Precise Near-Net-Shape Aluminum Parts

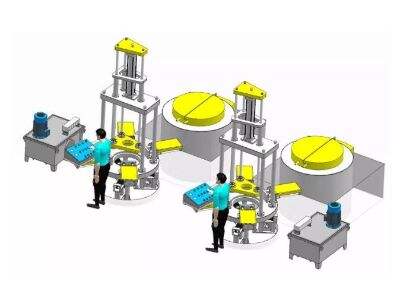

Rotational casting is a bit of a smart trick to make aluminum parts, which come out nearly perfectly shaped to their final shape. This technique involves slowly turning a mold while liquid aluminum is poured in. As the mold rotates, spreading metal evenly along its walls, it creates parts that are smooth, strong and close to their final design. No more cutting or fixing after the part is made. For example, if you want a round aluminum object like a pipe or vessel, rotational casting will shape it pretty much right out of the mold so there’s not much difference after being cast. It also cures some of the common issues such as air bubbles or uneven thickness. The parts emerge with a nice surface finish and good structure, which can be critical in industries like cars or electronics. Boqiao’s machines are made to maintain the right temperature and rotation, so that each one is exactly the same as the last, regular and dependable. Other times, scrap is generated en masse by other means shapes going wrong. Moving on to rotational casting – an absolute lifesaver in terms of material and time. The machines also can process various sizes and shapes, adding flexibility in factories. The fact that the parts don’t require much changing after they are cast means factories use less energy and chemicals, so the whole process is greener. It feels good to use machines that not only produce quality parts, but also have the environment in mind. That, Boqiao knows, is why this technology has to be perfected

Where To Get Wholesale Rotational Casting Machines For Producing Aluminum Efficiently

If you are looking to enhance the way your make parts by using the rotational casting process, then turn to Spin Casting. Wholesale machines purchase Buying machines in wholesale can save a lot of your money, and assist you in getting better tools for the factory. Boqiao, the company that makes the machines, sells them on a wholesale basis in an effort to develop products that allow industries to manufacture aluminum components as efficiently and with as little waste as possible. When you purchase from Boqiao, you receive hard-wearing, user-friendly machines that are crafted with care. There’s no need to worry about special settings because these machines come out of the box ready to do its job, and it can do so all day long with fewer problems. Factories using Boqiao’s machines may find their energy bills shrink as the machines perform work efficiently though this depends on where and how the technology is being used. The company also offers support and guidance to ensure machines run well. Boqiao is suitable for nearly all sizes of production: whether big or small factories, there are various models for customers

How to Get Low Cost Aluminum Part Casting Using Rotational Casting Technology

Aluminum parts can be expensive to make if the right process isn't chosen. But now, with rotational casting technology, companies like Boqiao can make aluminum parts in a manner that is both cheaper and faster. Rotational casting involves pouring molten aluminum into a hollow mold that spins slowly along two axes. The aluminum spreads in a uniform fashion along the inside of the spinning mold to create something close to the shape of novelty lit needed. The method may reduce post-casting work requirements, thereby reducing costs

One reason rotational casting is less expensive is because you create what we call near-net-shape parts. Near-net-shape is when the parts come out of the mold nearly ready to use, with minimal or no machine work required afterward. This results in less labor, energy and material usage. Here at Boqiao our rotational moulding machines are developed to produce this types of close-tolerance aluminum parts. That cuts down on waste and speeds up production, bringing the cost of the whole process down

Another reason rotational casting is economical is that it consumes less metal as compared to other processes. When you pour aluminum into a mold and apply some spin to it, the metal is forced evenly onto all the inside walls of the workpiece, so you don’t get thick, clunky parts. This decreases the amount of raw material needed and cuts down on the weight of the parts, which is crucial for industries like automotive and aerospace that can save energy and fuel through lighter-weight parts

Typical Problems in Rotational Casting Aluminum and Its Solutions

While rotational casting is a fantastic technique for manufacturing aluminum parts, it has its quirks. These problems help Boqiao make better machines and better products. One challenge is dialing in the appropriate thickness of the aluminum part. If the layer of metal is too thin, say some object will be weak. If it is too thick, it is overbuilt and has more weight than necessary. To help alleviate that, Boqiao’s machines have precise controls that modulate the spinning speed and temperature. ADDITIVEFurniers are now metal and pa designBack to Obed Vleugels (who is also one of the designers of Physalia): The UAMThermoplast-LayoutManager makes it possible for metal parts, springs, heating elements, sensors and other inserts to be integrated directly during the 3d print process. This even spreads out the aluminum mixture neatly as well as ensuring that a part has accurate thicknesses just where this is required

Another complication is getting the aluminum to cool in the right way. Cooling too quickly or unevenly can cause the part to crack or have rough surfaces. Boqiao relies on smart cooling systems and molds constructed from materials that can regulate temperate. This slows down how quickly the aluminum cools and minimizes defects

Occasionally, air bubbles or voids can develop in the aluminum components while casting. And these bubbles are making the parts weaker. Boqiao’s machines have features to evacuate air from the mold prior to and during casting. By managing the air pressure and employing vacuum systems, we minimize bubbles and create stronger parts Built in-house We also design our own machines

How Rotational Casting Machines Reduce Waste and Improve Accuracy of Aluminum Parts

One of the great benefits to using Boqiao’s rotational casting machines is that they help with the environment as well by decreasing waste. Leftover metal and scrap material are a problem for both the planet and the company’s costs when making aluminum parts. Both allow the casting of hollow objects, but with rotational casting, you only use enough metal to make the part and spin it so that it coats evenly where needed. That’s less metal to waste, compared with doing any of that in other ways, like casting dies or machining from big blocks of aluminum

As the parts emerge near-net-shape, they require less cutting and trimming. That’s less aluminum scrap, fewer chemicals or tools for finishing work. Mr. Boqiao’s machines can also recycle aluminum not used in the casting process. This metal can be re-melted and recycled, which means that there is less need to mine new aluminum, saving energy and natural resources

Not only does Boqiao’s rotational casting machines help to reduce waste, they also produce aluminum parts with high accuracy. The slow rotation allows the aluminum to spread naturally throughout the mould, delivering even surfaces and thickness. This helps parts fit together more smoothly in machines or products, and minimizes the risk of error or breakdown

Table of Contents

- How Rotational Casting Delivers Precise Near-Net-Shape Aluminum Parts

- Where To Get Wholesale Rotational Casting Machines For Producing Aluminum Efficiently

- How to Get Low Cost Aluminum Part Casting Using Rotational Casting Technology

- Typical Problems in Rotational Casting Aluminum and Its Solutions

- How Rotational Casting Machines Reduce Waste and Improve Accuracy of Aluminum Parts

AR

AR

BG

BG

HR

HR

CS

CS

FR

FR

DE

DE

EL

EL

HI

HI

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

ET

ET

GL

GL

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

SW

SW

BN

BN

LO

LO

MN

MN

MY

MY